-

Introduction to the Basic Situation of Company 3D PRINTING

Zhihui Precision can support you in effectively applying 3D printing technology. With 3D printing technology, you can quickly create durable, high-quality parts without investing in expensive equipment or developing complex molds. Our 3D printers—paired with precision 3d cnc processing support—use lasers to fuse metal powders or mixed wires, or materials such as plastic resins, to produce parts with intricate details and smooth surfaces that meet 3d cnc manufacturing standards.

Proper application of 3D printing processes can not only effectively enhance business efficiency and flexibility, whether by eliminating the need for design drawings and machining, or significantly shortening the delivery time of product development cycles.

We have years of seamless collaboration with our 3D printing partners, enabling us to provide a range of high-quality 3D printing (rapid prototyping) services, including FDM, SLA, SLS, and SLM. 3D printing breaks through material and structural limitations, allowing the use of various materials such as metals and plastics, and offers options for both prototype design and production. Particularly for parts with complex features, it ensures precise molding, guaranteeing the functionality and mechanical properties of the components. 3D printing is an excellent method for manufacturing one-off parts or small-batch products, capable of producing complex geometries that traditional manufacturing processes cannot achieve. Additionally, our large-scale printing capability meets the demand for high-precision manufacturing of large parts, effectively reducing splicing errors. With exceptional technical expertise, we provide a one-stop solution for the manufacturing of complex parts.

Based on the latest 3D printing technology, we can help you quickly and successfully implement 3D product printing, delivering significant business benefits and technological advantages of combined 3D printing and 3d cnc solutions.

Overview of 3D PRINTING (Metal and Plastic)

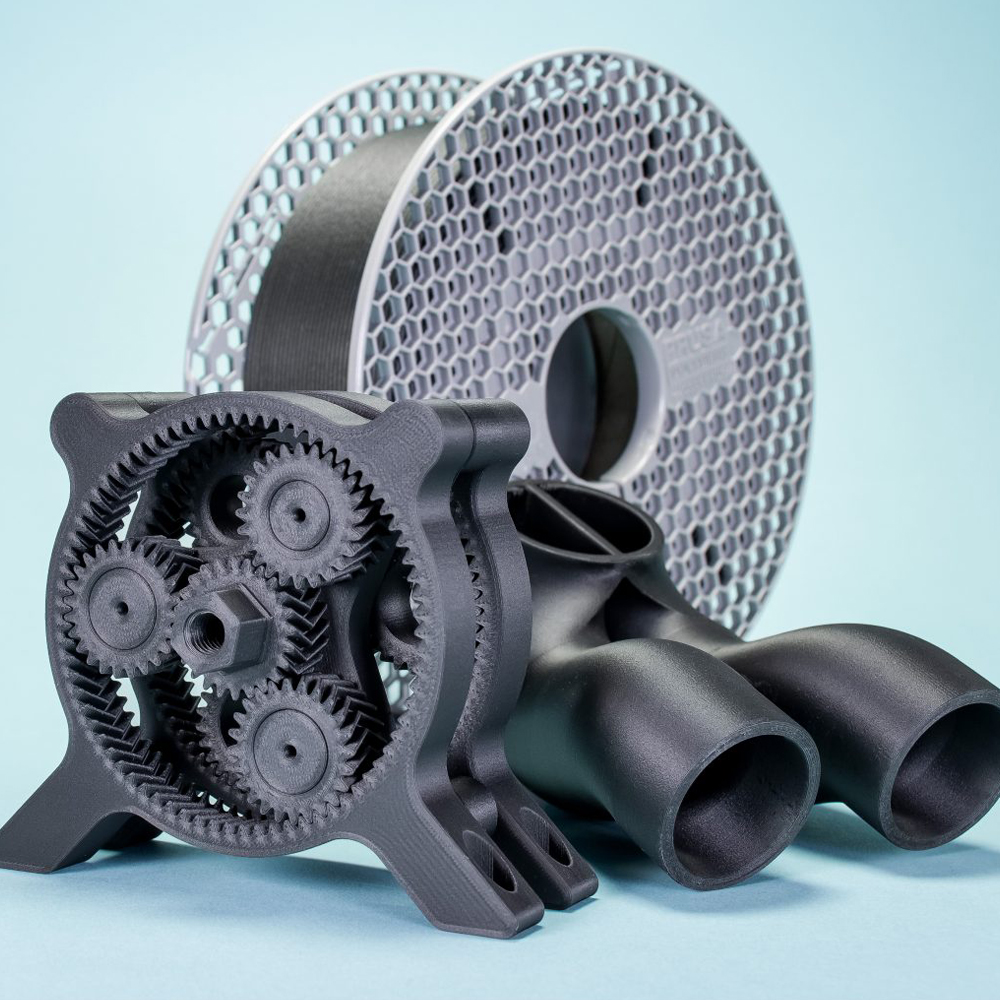

Overview of 3D Printing (Metal and Plastic) 3D Printing, also known as Additive Manufacturing, is a technology that creates three-dimensional objects by layering materials. It is widely used in prototyping, customized production, and the manufacturing of complex parts. Based on material types, 3D printing can be divided into metal and plastic categories. Metal 3D Printing Metal 3D Printing uses metal powders or wires as raw materials, melting and layering them with high-energy lasers or electron beams. Common metal materials include titanium alloys, aluminum alloys, stainless steel, and nickel-based alloys. Technologies: 1. Selective Laser Melting (SLM): Uses a laser beam to selectively melt metal powders, building layers. 2. Electron Beam Melting (EBM): Uses an electron beam to melt metal powders in a vacuum, suitable for high-melting-point materials. 3. Direct Metal Deposition (DMD): Deposits metal powders or wires into a molten pool through a nozzle. Advantages: • Capable of manufacturing complex geometric metal parts. • High material utilization, reducing waste. • Suitable for high-strength and high-temperature metal parts. • Supports customization and small-batch production. Applications: • Aerospace: Engine components, turbine blades, etc. • Medical: Customized implants (e.g., titanium alloy bones). • Automotive: Lightweight parts, high-performance components. • Mold Manufacturing: Direct manufacturing of complex molds. Plastic 3D Printing Plastic 3D Printing uses plastic materials (e.g., ABS, PLA, nylon, resin) as raw materials, layering them through technologies such as fused deposition, photopoly merization, or powder sintering. Technologies: 1. Fused Deposition Modeling (FDM): Melts plastic filaments through a heated nozzle, building layers. 2. Stereolithography (SLA/DLP): Uses UV lasers or projectors to cure liquid resin, layer by layer. 3. Selective Laser Sintering (SLS): Sinters plastic powder with a laser, suitable for complex structures. Advantages: • Low cost, suitable for prototyping and small-batch production. • Diverse materials to meet different performance needs. • Fast manufacturing and flexible design. • Supports multi-color and multi-material printing. Applications: • Consumer Goods: Toys, household items, electronic housings. • Medical: Surgical guides, prosthetics, dental models. • Education: Teaching models, experimental tools. • Industrial: Functional prototypes, jigs, and fixtures.

3D printing technology, in both metal and plastic fields, demonstrates significant potential and is driving manufacturing toward digitization, customization, and efficiency.

3D PRINTING Process & Material We Use

| Metal | Aluminum, Copper, Brass, Stainless steel, Titanium |

| Resin | PC, ABS, PP, ASA, POM, etc. |

| Nylon | PA6/66, PA12 |

| Elastoplastic | TPU, TPE, SEBS, And More than 70 materials available. |

For Metals material, more details are as below description: | |

| Aluminum | Aluminum is a highly ductile metal, known for its ease of machining. It offers an excellent strength-to-weight ratio and is available in various types to suit a wide range of applications. |

Copper | Copper boasts outstanding thermal conductivity, electrical conductivity, and plasticity. It is also highly ductile, corrosion-resistant, and easily weldable. |

| Brass | Brass is prized for its desirable properties in numerous applications. It features low friction, excellent electrical conductivity, and a distinctive golden appearance. |

Stainless Steel | Stainless steel, a low-carbon steel, is highly valued for its properties in industrial applications. It typically contains a minimum of 10% chromium by weight. |

Titanium | Titanium is renowned for its exceptional material properties, making it ideal for demanding applications. These include superior resistance to corrosion, chemicals, and extreme temperatures, as well as an impressive strength-to-weight ratio. |

Metal And Plastic Materials And Product Cases

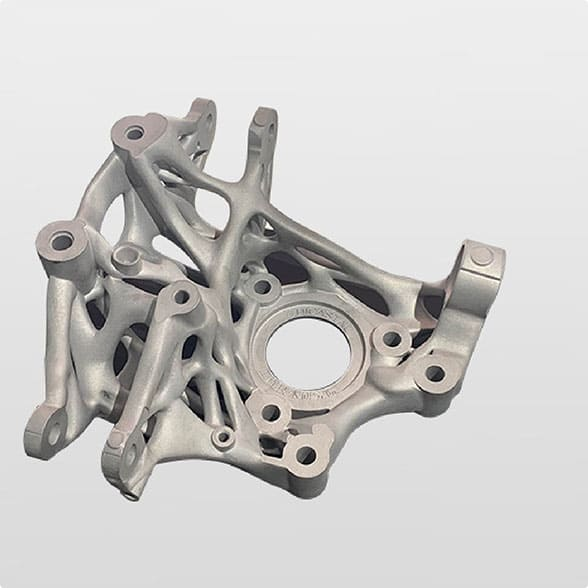

Forming process: SLM selective laser fusion

Material introduction: Aluminum alloy 6061 is a heat treatment strengthening alloy, which has good formability, weldability and machining, as well as medium strength, and can maintain good operability after annealing.

Key characteristics: excellent processing performance, excellent welding and plating, good corrosion resistance, high toughness and no deformation after processing, easy polishing, coloring, and oxidation, and other excellent characteristics.

Delivery time: 7 days

Forming process: SLM selective laser fusion

Material introduction: excellent corrosion resistance, and belongs to medical and food grade materials, widely used in aerospace, handboard, mold, medical, electronic, jewelry,and other fields.

Key characteristics: 316L is a high chromium stainless steel with excellent corrosion resistance and is a food grade and medical material.

Delivery time: 72 h

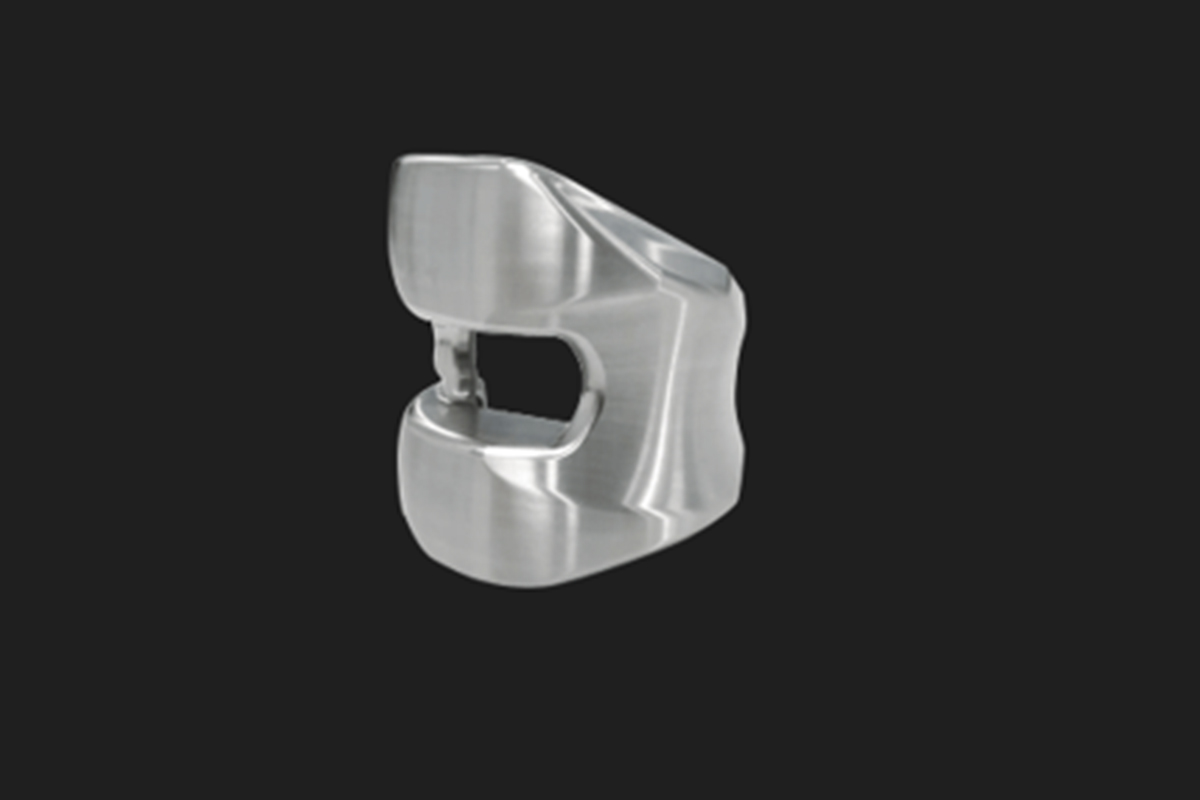

Forming process: SLM selective laser fusion

Material introduction: This material is a medium-strength α-β type two-phase titanium alloy with excellent mechanical properties, biocompatibility, and corrosion resistance, and has been widely used in aerospace, medical, chemical, and other fields.

Key characteristics: This material can achieve high specific strength, light weight, high strength, and long working temperature up to 400℃.

Delivery time: 4 days

Forming process: SLM selective laser melting

Material introduction: It can manufacture various complex parts and components, which are widely used in aerospace, nuclear industry, petrochemical industry, and extrusion molds.

Key characteristics: It has good comprehensive performance in the temperature range of-253~650℃, the yield strength below 650℃ ranks first among the deformation high temperature alloys, and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, as well as good processing performance and welding performance.

Delivery time: 8 days

Considerations for Custom 3D Printing of Metal Parts

When preparing to use metal materials for 3D printing products, the following factors need to be carefully considered and confirmed to ensure you select the appropriate material for printing your product:

Type of Metal

There are many types of metals, each with its unique properties. When choosing a metal for creating 3D-printed parts, you need to consider the characteristics of the metal and how they align with your requirements.

Strength of Metal

The strength of a metal is one of its most important properties. You need to consider how strong the metal needs to be to meet the product's demands.

Hardness of Metal

The hardness of the metal is another critical characteristic to consider. The harder the metal, the more challenging it is to print.

Corrosion Resistance of Metal

The corrosion resistance of the metal is equally important. The better the corrosion resistance, the longer the lifespan of the parts.

Cost of Metal

As with all traditional manufacturing processes, the more expensive the metal, the higher the cost of the 3D-printed parts made from that metal.

Application of Metal Products

Based on the actual application of the product, prototype parts made of metal materials are selected for testing. This step is indispensable in the process of new product development and product shape research.

Advantages of 3D Printing

Customized, Cost-Effective Manufacturing of Complex Geometries:

This technology allows for the easy creation of customized geometric parts, and increased complexity does not incur additional costs. In some cases, 3D printing is cheaper than subtractive manufacturing methods because it does not waste excess material.

Lower Startup Costs:

Since no molds are required, the associated costs of this manufacturing process are relatively low. The cost of a part is directly related to the amount of material used, the time required to build the part, and any necessary post-processing.

Fully Customizable:

Because the process is based on computer-aided design (CAD), product modifications can be easily made without impacting manufacturing costs.

Ideal for Rapid Prototyping:

Since the technology supports small-batch and in-house production, it is ideal for prototyping. This means products can be created faster compared to traditional manufacturing techniques, without relying on external supply chains.

Ability to Manufacture Parts with Specific Properties:

Although plastics and metals are the most commonly used materials in 3D printing, specially tailored materials can also be used to create parts with desired properties. For example, parts can be manufactured with high heat resistance, water repellency, or higher strength for specific applications.

Applications of 3D Printing

3D-printed parts can be widely applied across various product types and industries:

Custom Prototyping: Rapidly transform design concepts into functional and visual physical prototypes.

Custom Tools and Fixtures: Produce tools and jigs tailored to specific production needs, enhancing efficiency.

Medical Implants and Prosthetics: Develop customized implants and prosthetics for improved fit and comfort.

End-Use Components: Manufacture ready-to-use parts suitable for diverse applications.

Architectural Models: Create detailed models for design and planning purposes.

Custom Consumer Products: Craft unique items such as jewelry, phone cases, and home goods.

Educational Models: Produce precise models for research and teaching purposes.

Replacement Parts: Print rare or obsolete components for maintenance and repair needs.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文