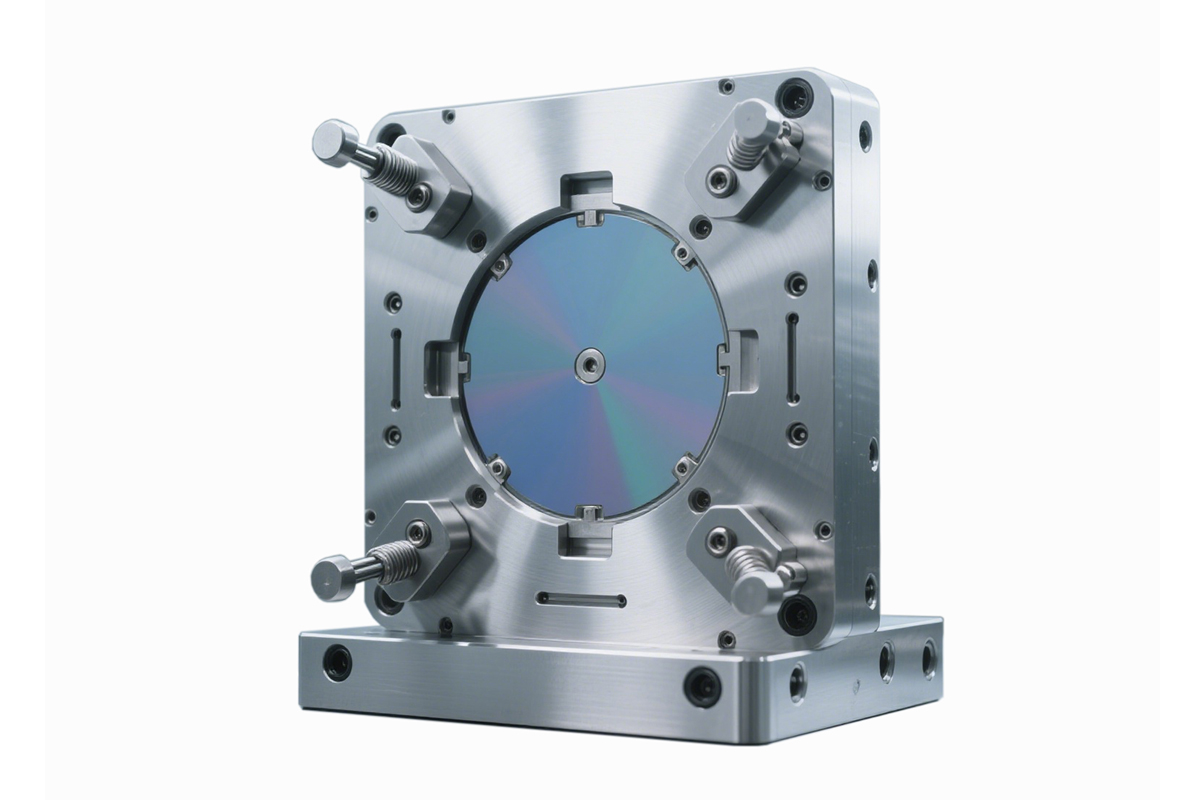

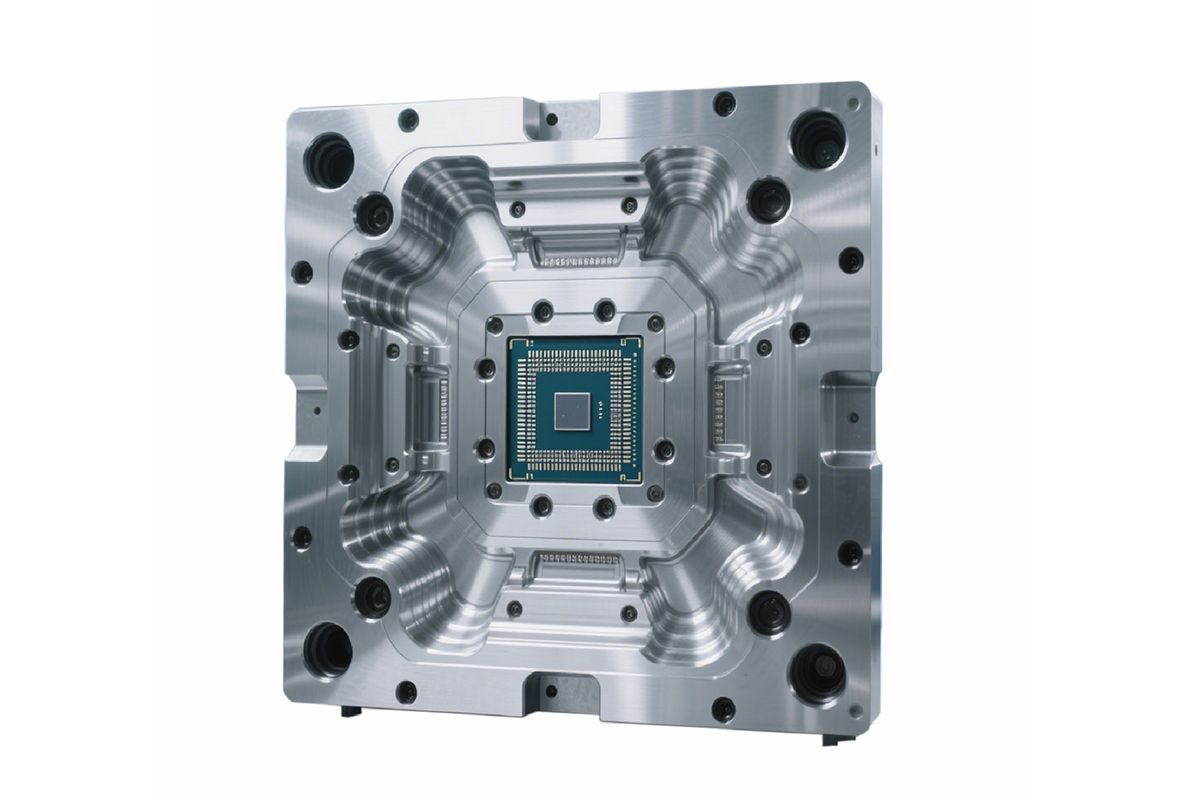

Vacuum Chamber Assembly

Product Name: Vacuum Chamber Assembly

Material: 316L Stainless Steel

Dimensions: 450×430×220 mm

Processing Method: 5 axis CNC service

Product Features:

Our 5-axis CNC-machined vacuum chamber demonstrates exceptional technical capabilities in precision manufacturing. Designed to meet semiconductor equipment's stringent requirements for hermetic sealing (±0.005mm geometric tolerances) and ultra-clean surfaces, we achieve seamless integration of complex curvatures, specialized flow channels, and high-precision interfaces through multi-axis synchronous machining, eliminating repositioning errors.

Specialized tooling and temperature-controlled processes overcome deformation challenges in thin-wall stainless steel machining. Combined with mirror polishing and particulate control technology, we guarantee surface roughness of Ra≤0.1μm, ensuring stability in 10⁻⁶ Pa vacuum environments.

With proprietary CAM programming optimization and real-time inspection systems, we achieve a 99% yield rate for complex structures. This solution provides semiconductor equipment manufacturers with core chamber components that deliver both extreme precision and reliability, setting new standards in vacuum-critical applications.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文