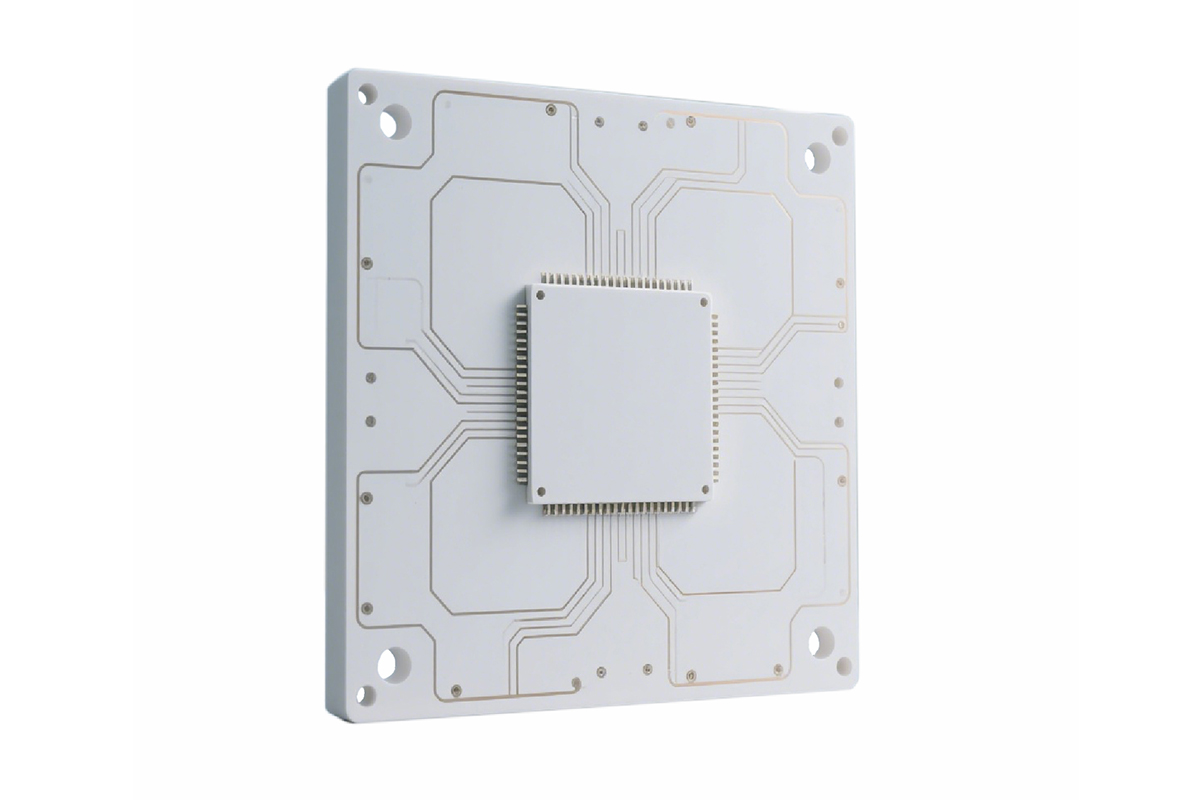

Ceramic Substrate

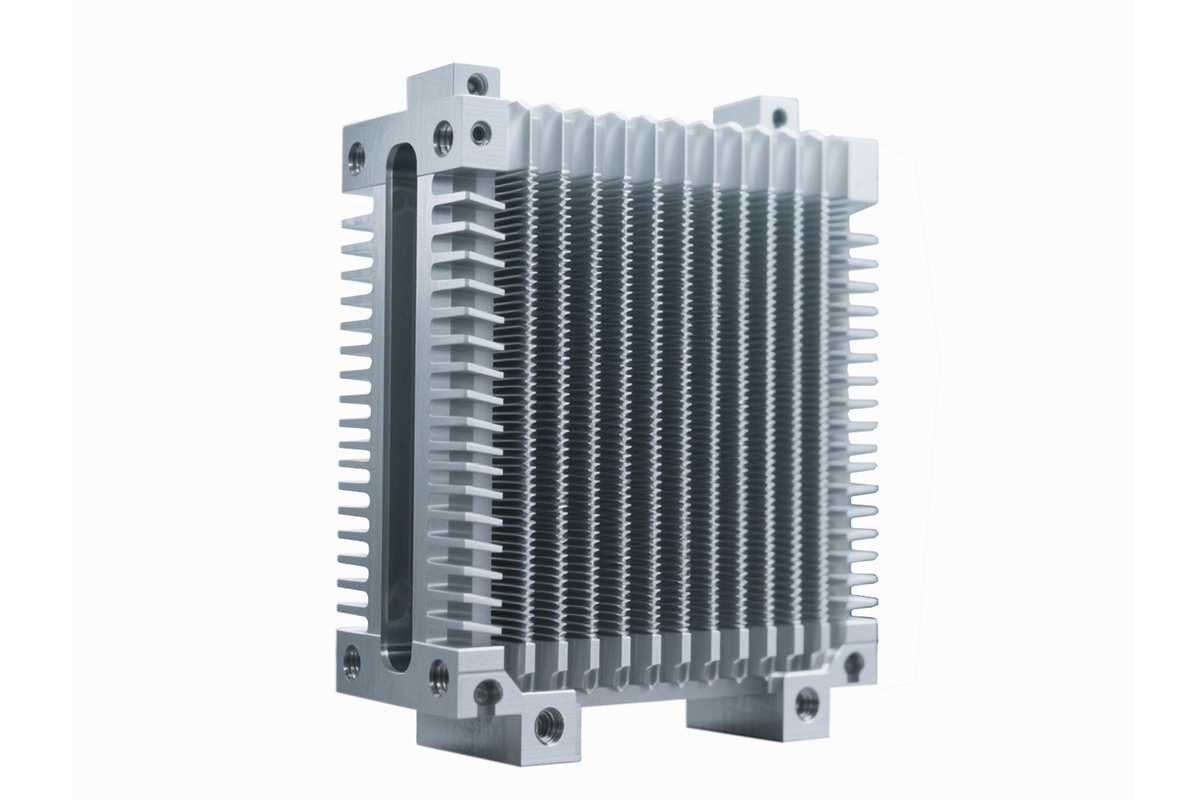

Product Name: Ceramic Substrate

Material: Aluminum Nitride (AlN)

Dimensions: 120*120*15 mm

Processing Method: 5 axis machining services

Product Features:

As a critical component in semiconductor manufacturing, ceramic substrates demand extreme precision and structural complexity. Our advanced 5-axis CNC technology overcomes the machining challenges posed by the high hardness and brittleness of ceramics. Through precision multi-axis synchronization and dynamic toolpath optimization, we achieve single-step machining of intricate micro-holes, curved surfaces, and irregular contours, with dimensional tolerances consistently controlled within ±0.005 mm.

To address ceramics' susceptibility to chipping, we developed proprietary custom tools and an intelligent temperature-controlled cooling system, combined with layered progressive cutting techniques. This ensures a surface finish of Ra 0.2 μm, free from micro-cracks and with exceptional edge integrity.

A closed-loop quality inspection system guarantees product uniformity, delivering high-reliability, high-performance precision ceramic substrate solutions for semiconductor equipment. Our expertise in machining advanced ceramics sets a benchmark for the industry.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文