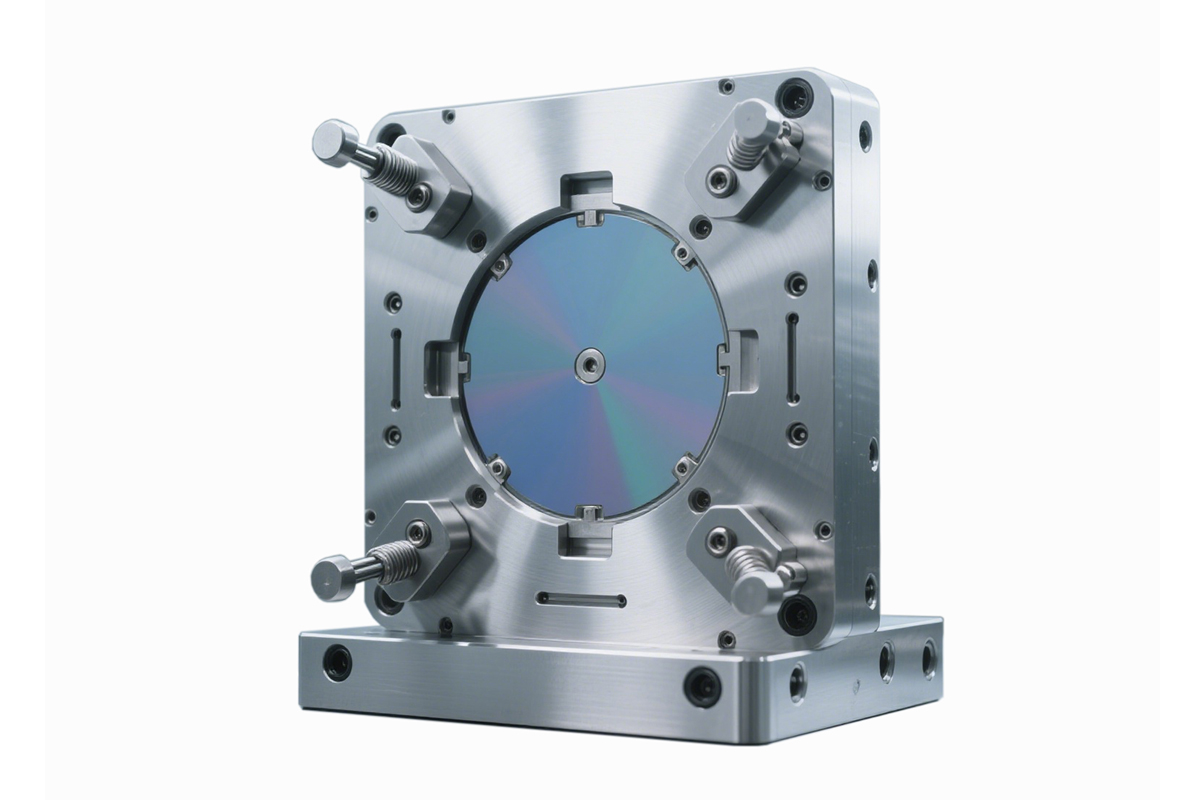

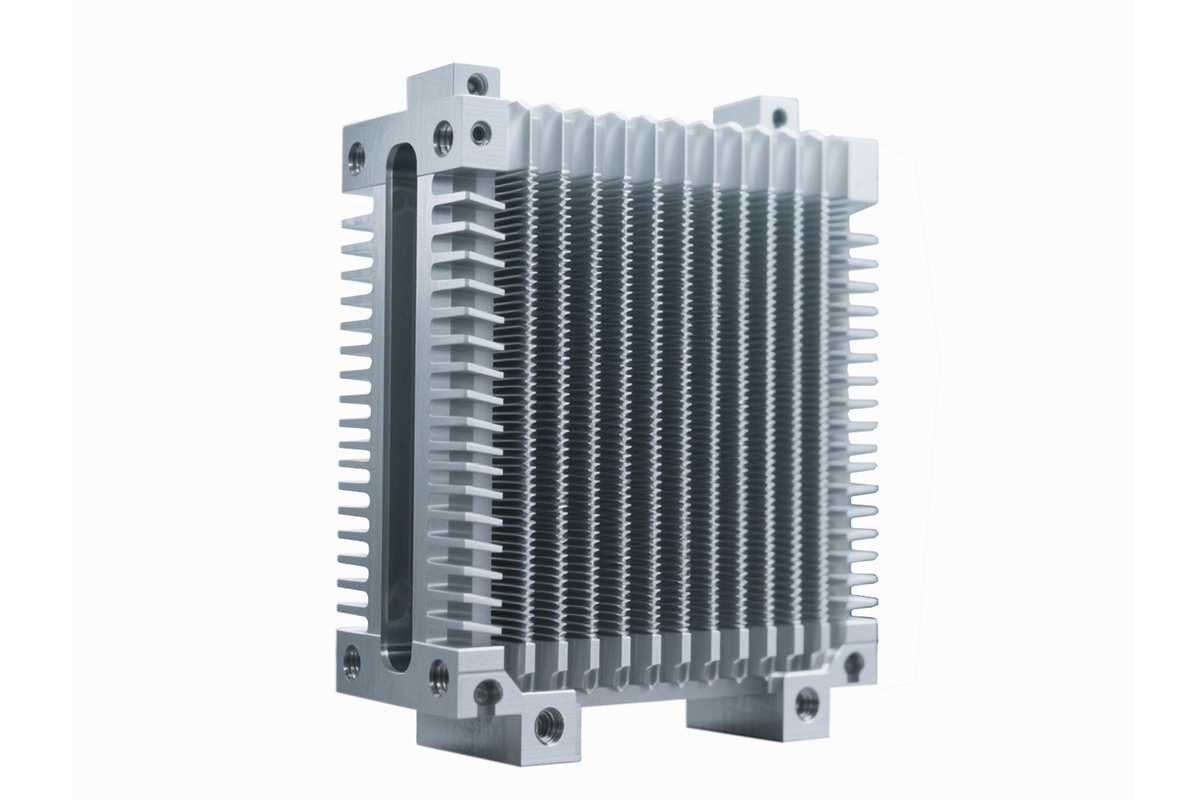

Wafer Clamp Assembly

Product Name: Wafer Clamp Assembly

Material: 316L Stainless Steel

Dimensions: 360*400*200 mm

Processing Method: 5 axis manufacturing

Product Features:

This wafer clamp assembly is manufactured through advanced 5-axis CNC integrated machining, overcoming traditional processing limitations to perfectly meet the nanometer-level precision requirements of wafer handling.

To achieve micron-level geometric tolerances, multi-axis synchronization technology enables omnidirectional precision cutting, completing multi-surface high-gloss machining in a single setup, eliminating repositioning errors. Material stress simulation optimizes cutting parameters, ensuring structural stability and deformation resistance while complying with cleanroom dust-free and contamination-free standards.

Real-time in-process inspection and an intelligent compensation system guarantee critical dimensional accuracy within ±0.002 mm and a surface roughness of Ra ≤ 0.1 μm. The assembly delivers zero-defect reliability for wafer transfer and positioning, showcasing our company’s unparalleled expertise in high-precision semiconductor equipment manufacturing.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文