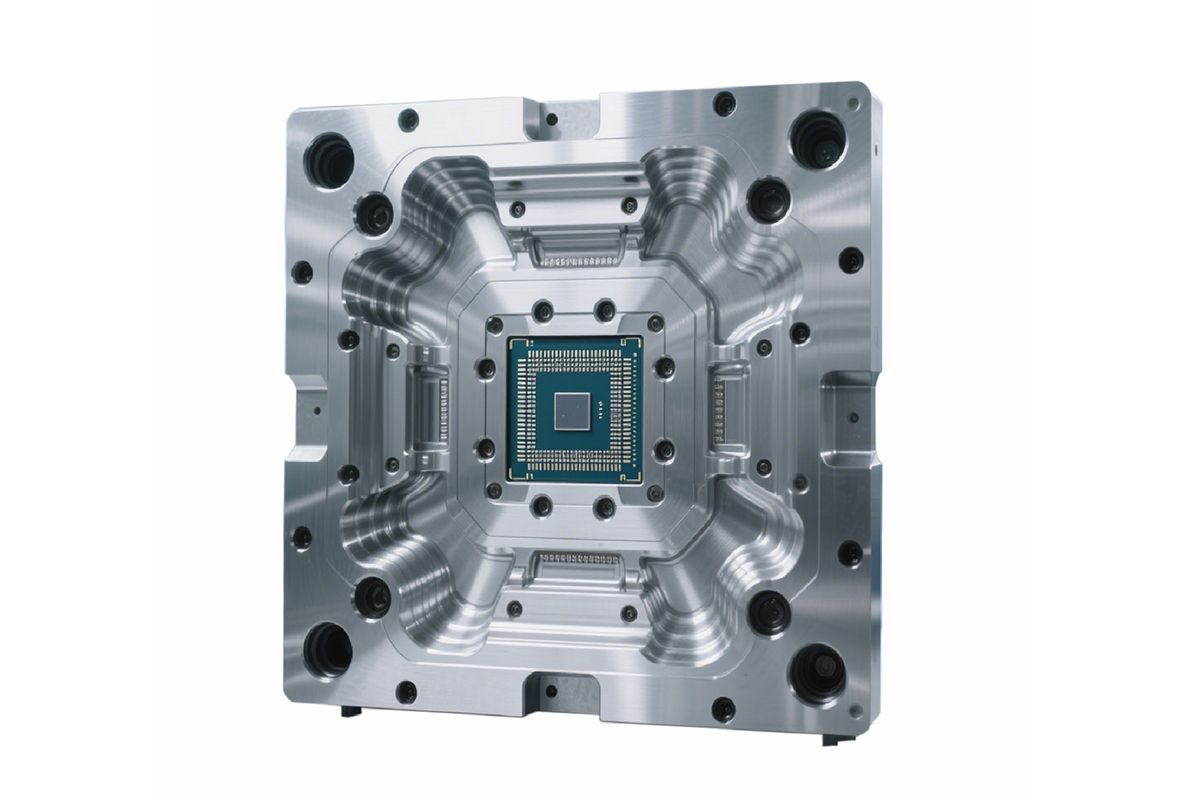

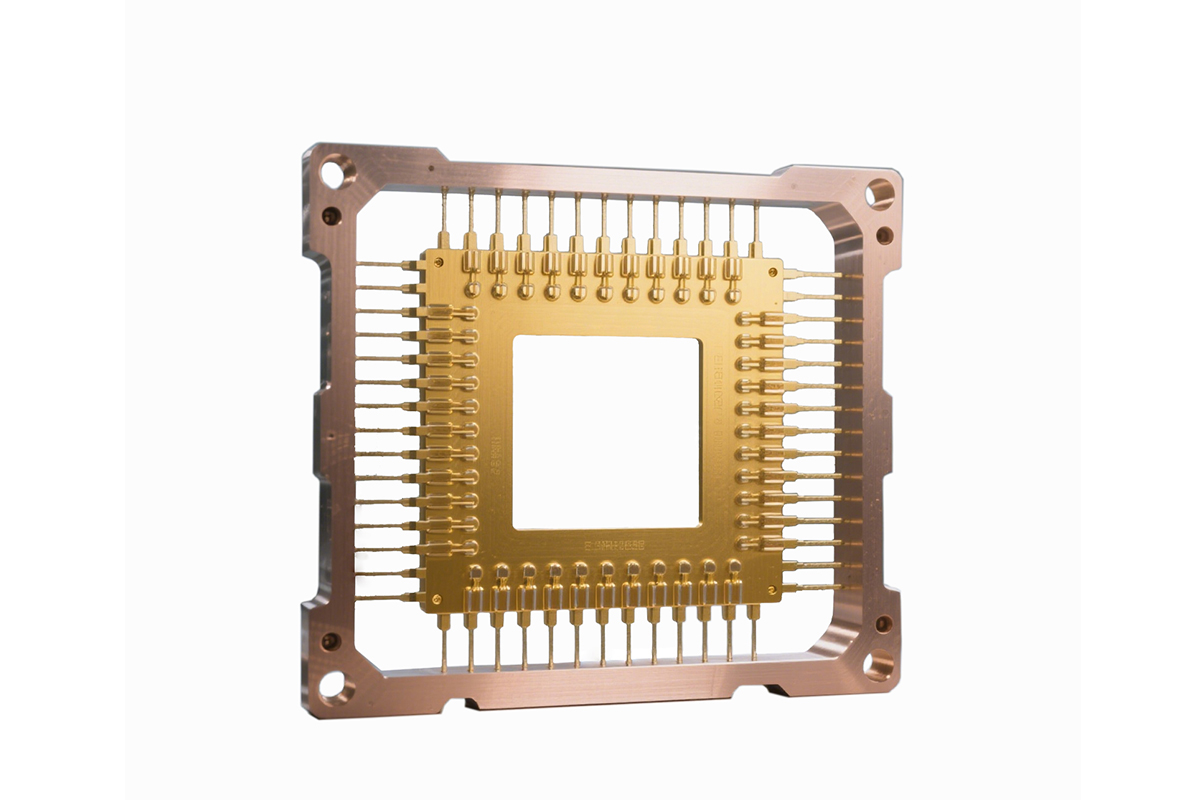

Encapsulation Mold

Product Name: Encapsulation Mold

Material: SKD 11

Dimensions: 450*450*180 mm

Processing Method: 5 axis manufacturing

Product Features:

As a core component of semiconductor encapsulation, this mold is renowned for its ultra-high precision, complex multi-curved structure, and stringent tolerances (±0.002mm), posing extreme challenges to machining processes. To address its hard material properties and miniaturized design, our company leverages 5-axis CNC technology to achieve multi-angle synchronized machining, completing complex features such as deep cavities, irregular holes, and micro-channels in a single setup, eliminating errors from repeated clamping and ensuring dimensional consistency across the entire part.

Integrated with intelligent temperature control and dynamic tool compensation technologies, the process effectively suppresses thermal deformation and vibration, achieving a surface roughness of Ra 0.1μm. This significantly enhances encapsulation efficiency and mold lifespan. Through process simulation optimization and full-process precision inspection, we deliver cutting-edge mold machining solutions to the semiconductor industry, combining stability and mass-production advantages.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文