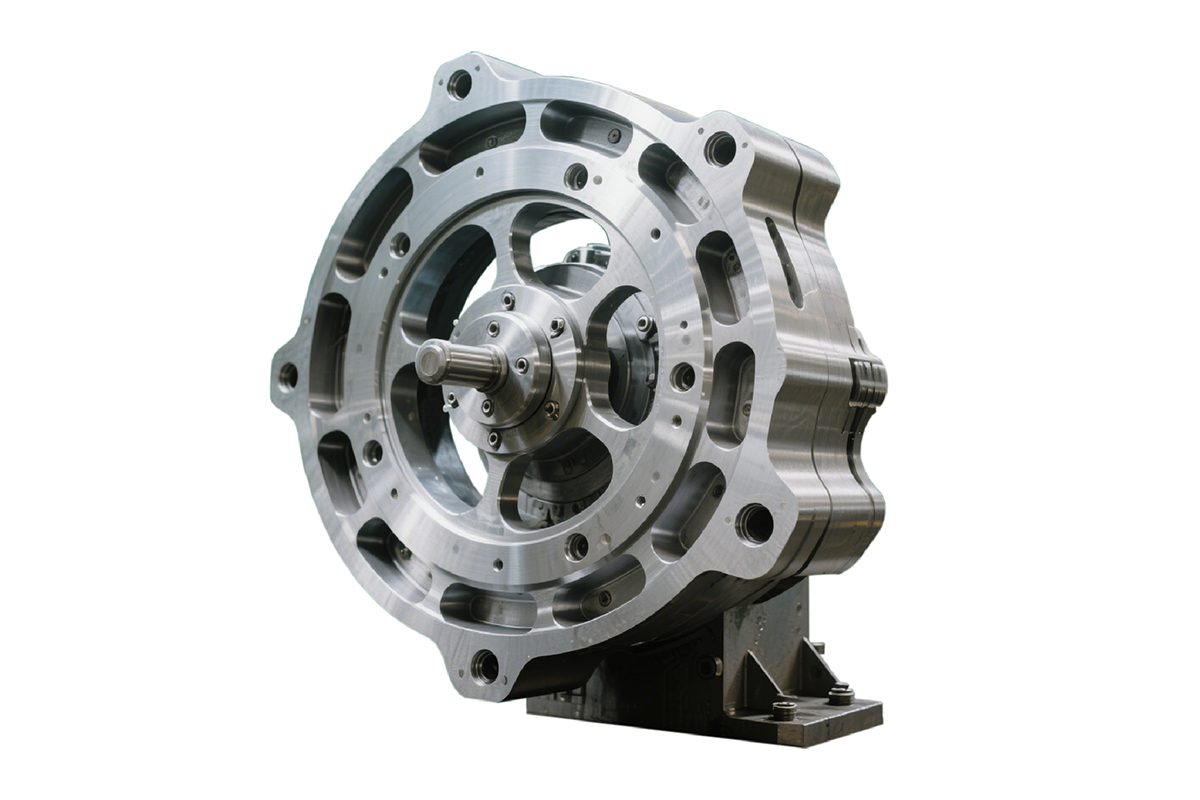

Transmission Gear

Product Name: Transmission Gear

Material: 45# Steel

Dimensions: D350 × 320 mm

Processing Method: 5 axis machining services

Product Features:

This transmission gear is manufactured using integrated 5-axis CNC precision machining technology, breaking through the limitations of traditional processes to achieve highly efficient forming of complex curves, helical tooth profiles, and high-precision meshing surfaces.

To meet the stringent demands of the marine industry for high-pressure resistance, fatigue resistance, and low-noise operation, our 5-axis simultaneous machining technology overcomes challenges such as multi-angle deep cavity machining and seamless transitions for irregular contours. This ensures a tooth surface roughness of ≤ Ra 0.8 μm and geometric tolerance accuracy of ±0.005 mm, significantly improving load-bearing capacity and transmission smoothness.

The entire machining process utilizes a dynamic compensation system to minimize errors from repeated clamping, integrating all steps efficiently while balancing ultra-precision machining with batch stability. We provide customized gear machining solutions for marine power systems, delivering high reliability and extended service life.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文