In modern manufacturing, CNC (Computer Numerical Control) machining technology has become the mainstream method for precision manufacturing of metal parts. Depending on the degrees of freedom in the equipment's movement, it is commonly divided into 3-axis CNC machining and 5-axis CNC machining. Although both belong to the CNC machining system, they show significant differences in terms of structural complexity, processing efficiency, and application range.

Number of Axes Determines Machining Capabilities

3-axis CNC machining refers to the linear movement of the tool along the X, Y, and Z axes. This type of machining is suitable for flat parts or simple geometric structures, with clear machining paths and low costs, making it widely used in initial processing and mass production scenarios.

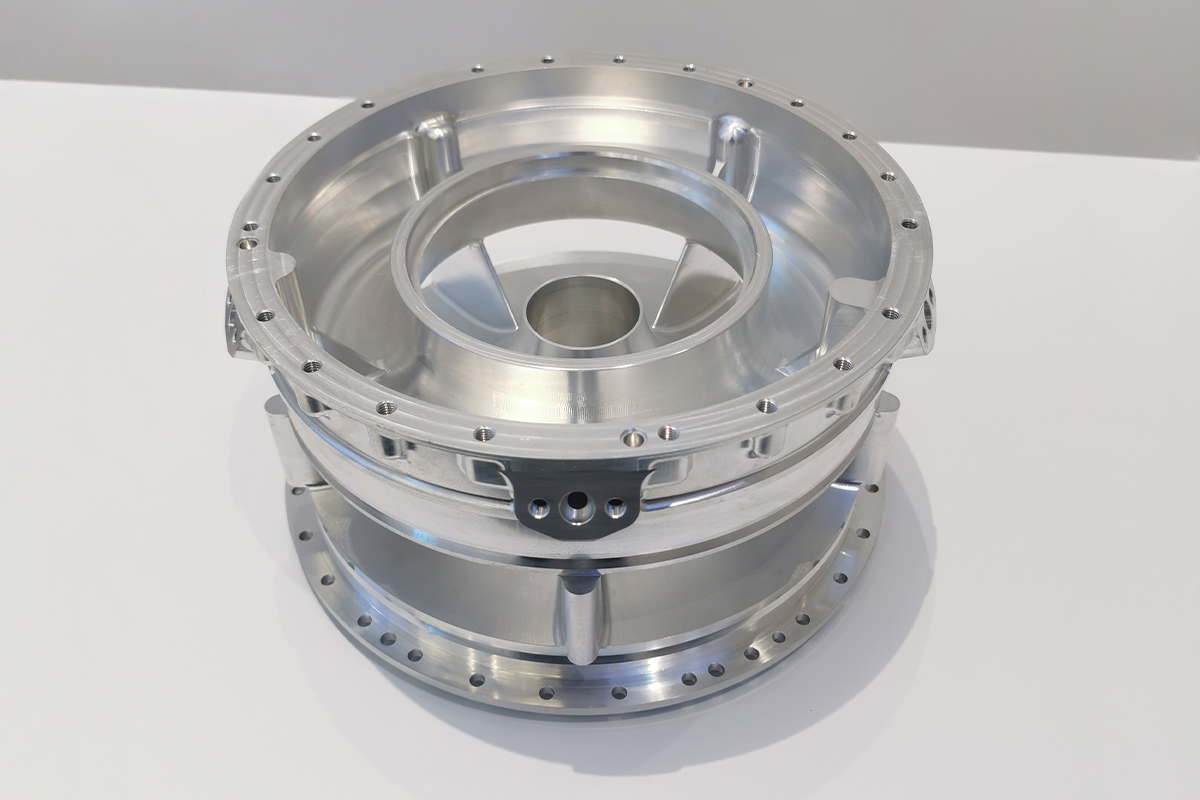

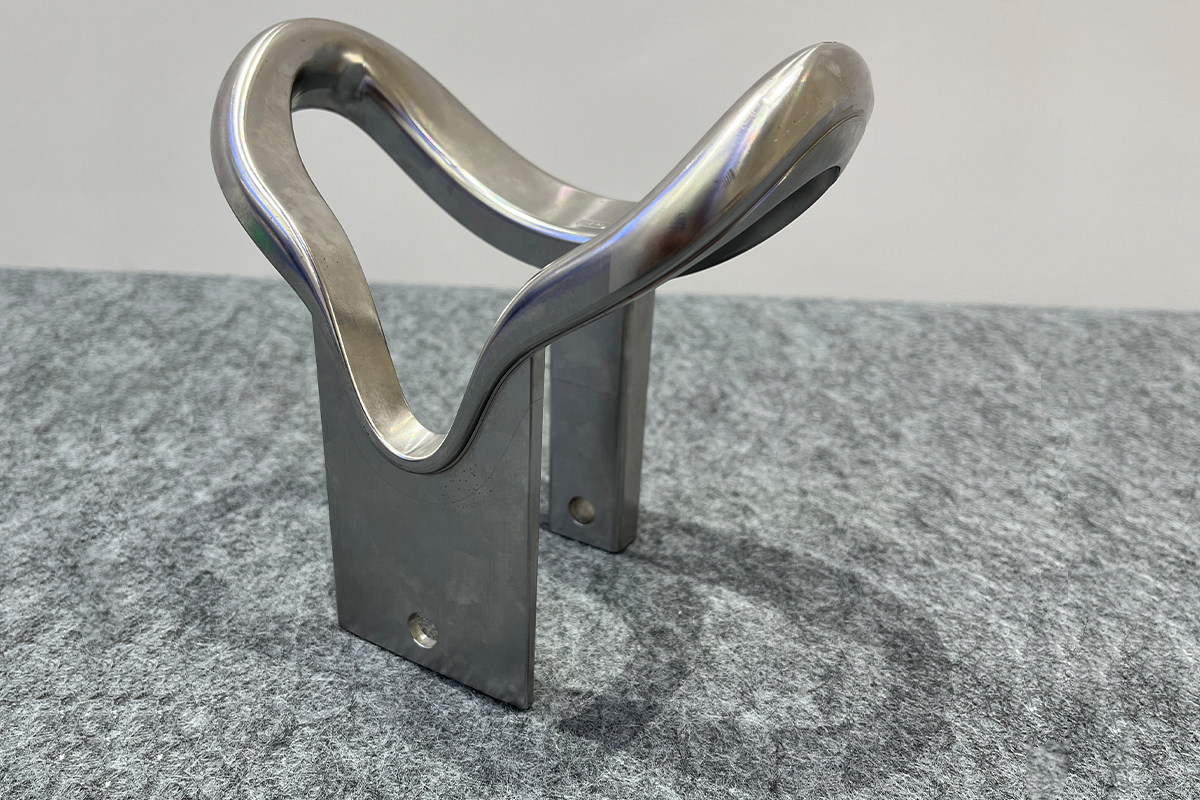

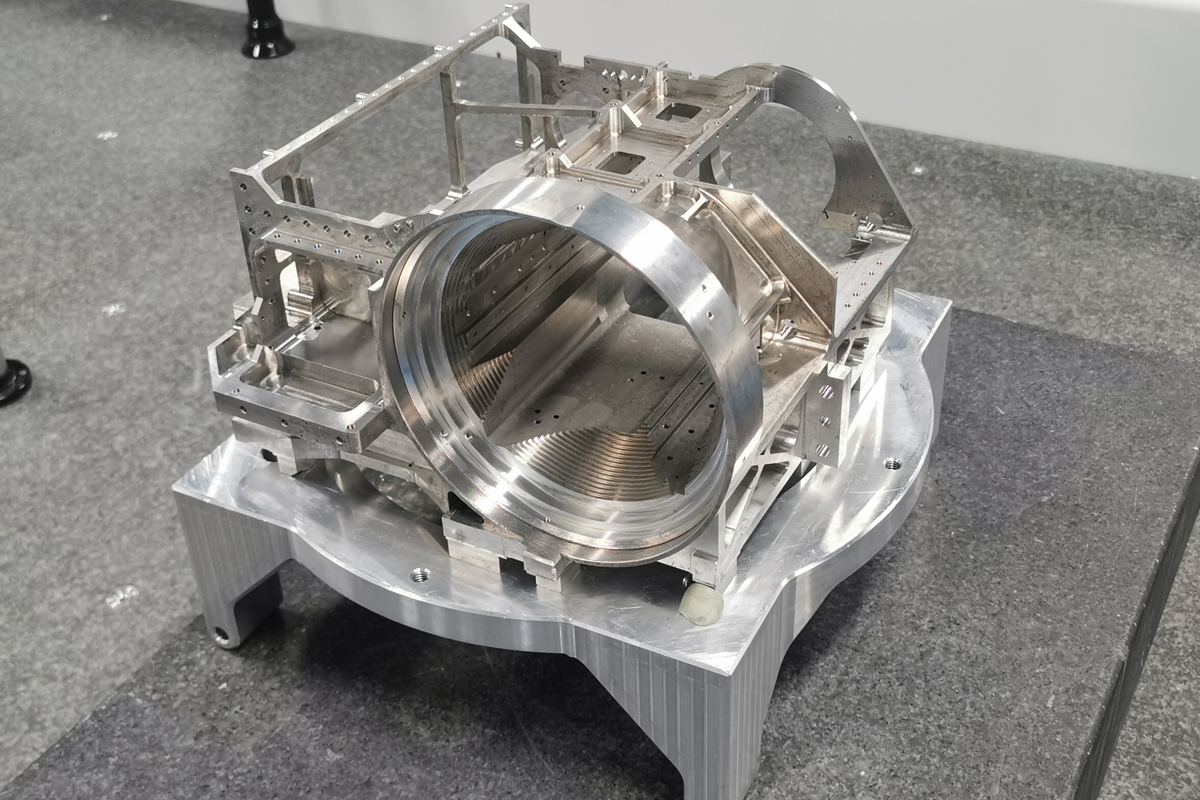

5-axis CNC machining builds upon the original three axes by adding two rotational axes (usually the A and B axis or C axis), allowing the tool to access the workpiece from more angles. Its biggest advantage is that it can complete complex curved surfaces or multi-surface machining in one setup, significantly reducing the number of setups and positioning errors.

Differences in Efficiency and Accuracy

In terms of efficiency

3-axis CNC machining processes are relatively straightforward, but when dealing with polyhedral parts or inclined surfaces, multiple setups or repositioning are often needed, affecting overall production time.

5-axis CNC machining leverages flexible tool angle adjustments to complete precise multi-surface cutting in one go, greatly enhancing machining efficiency.

In terms of accuracy

5-axis CNC machining offers higher consistency and repeatable positioning capabilities, making it especially suitable for fields with high demands for machining accuracy, such as aerospace and medical instruments.

3-axis CNC machining is often limited by tool length and interference risks when dealing with deep cavity structures, making it challenging to ensure machining accuracy and surface quality.

Technical Threshold and Return on Investment

5-axis CNC machining offers numerous technical advantages, but its equipment acquisition costs, operational programming difficulty, and maintenance requirements are relatively higher, making it suitable for high-end manufacturing enterprises and applications requiring high part complexity.

3-axis CNC machining, with its low entry threshold and high versatility, remains the preferred choice for many small and medium-sized manufacturing enterprises.

Select According to Need, Integrate and Develop

Overall, 3-axis CNC machining is suitable for simple structure and budget-limited mass production needs, while 5-axis CNC machining is better suited for high-complexity, high-precision, and high-value part manufacturing. As the manufacturing industry continues to move towards intelligence and precision, both will continue to play their respective advantages in different dimensions, jointly promoting modern manufacturing to a new level. The choice of which machining method to use should be based on a comprehensive assessment of the complexity of product design, accuracy requirements, and company budget.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文