What is Custom Machining Service?

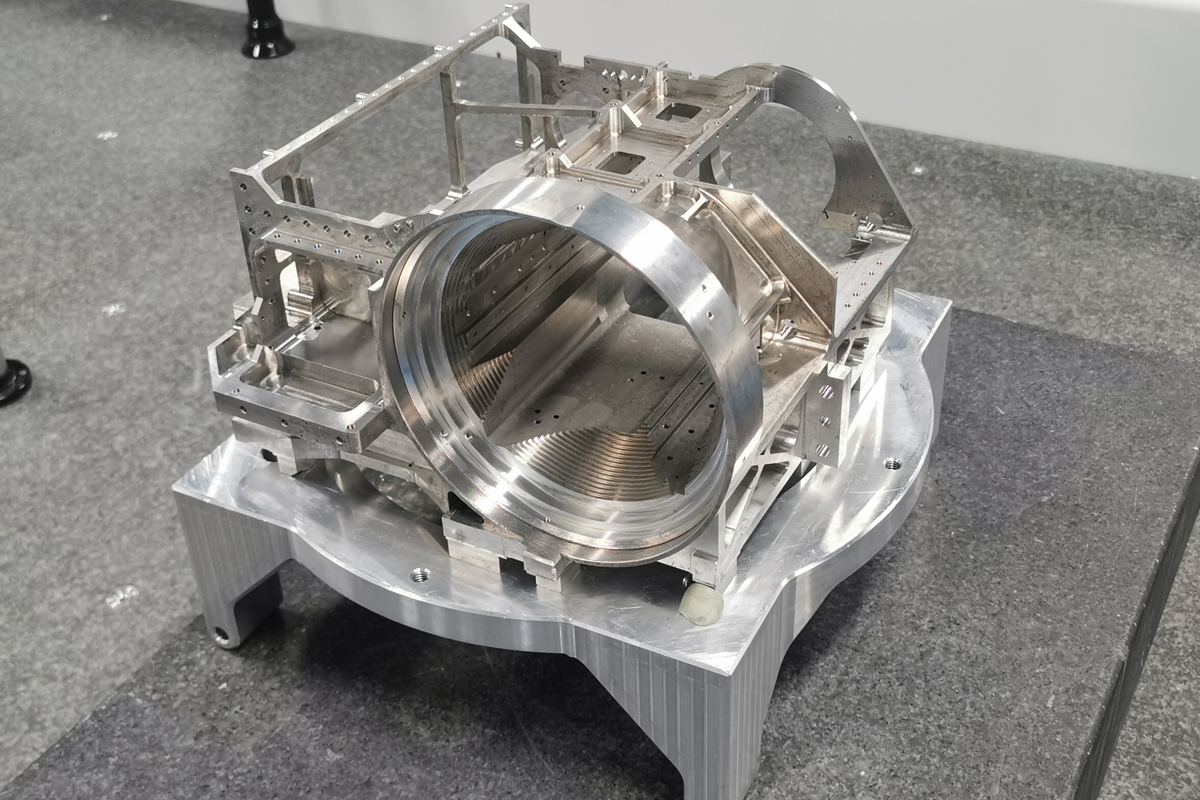

Custom machining service refers to the comprehensive process service of part machining, assembly, or surface treatment based on drawings, designs, or technical requirements provided by the customer. Unlike standardized mass production, custom machining service emphasizes precision, flexibility, and client exclusivity.

Its processing scope covers a variety of manufacturing technologies, including CNC turning, milling, EDM, laser cutting, and metal 3D printing, which can be widely applied in high-end fields such as aerospace, medical equipment, automotive parts, and robotics.

Zhihui Precision, as a professional machining manufacturer, can provide comprehensive custom machining services.

Key Features of a Quality Custom Machining Supplier

Choosing the right custom machining supplier is key to ensuring smooth project delivery and reliable quality. Quality suppliers typically have the following advantages:

High-precision equipment configuration: such as five-axis CNC machines, CNC lathes, and high-speed milling machines;

Complete quality management system: certified with ISO 9001, AS9100, etc., ensuring controllability and traceability of each process;

Strong technical support capabilities: can assist clients in optimizing designs, improving machining feasibility, and cost control;

Fast response speed: short lead time from quotation to sample delivery, adapting to the fast-iterating market demands.

Choosing Zhihui Precision as an experienced custom machining supplier can effectively reduce trial-and-error costs and shorten product development cycles.

Comprehensive Advantages of Custom Machining Factories

Modern custom machining factories are not just machining workshops but comprehensive platforms integrating design support, process optimization, quality inspection, and logistics services.

Their advantages mainly manifest in the following aspects:

High level of automation: introducing robotic-assisted machining and intelligent production lines to improve production efficiency and consistency;

Strong customization capabilities: have the ability for flexible production of multiple varieties and small batches to meet clients' special structural or functional requirements;

Outstanding cost optimization capabilities: control costs through internal process integration, centralized material procurement, and streamlined processes;

International service capabilities: can provide export certification, custom packaging, and global distribution support for overseas clients.

The excellent custom machining factory of Zhihui Precision is not only an executor of product machining but also an important partner of the client's R&D team.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文