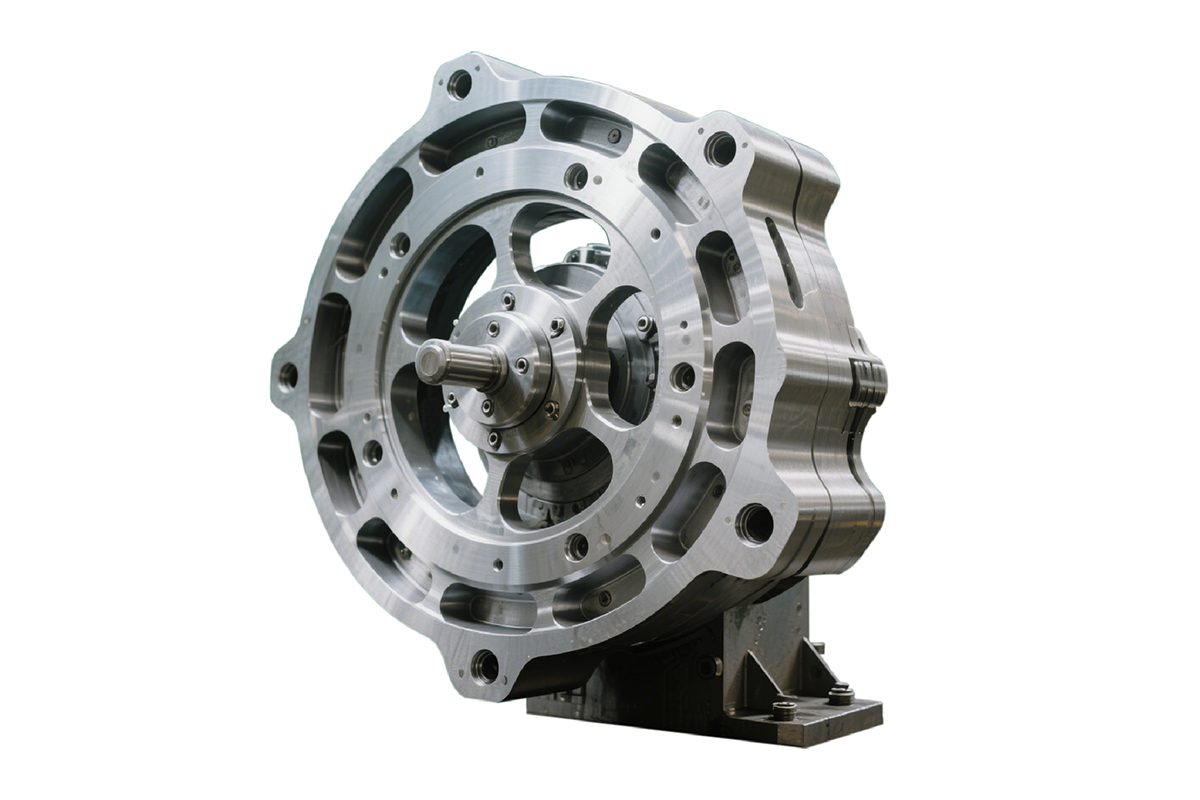

Impeller for Shipbuilding

Product Name: Impeller

Material: Titanium Alloy

Dimensions: Ø350 × 80 mm

Manufacturing Process: 5-Axis CNC Machining

Product Features:

As a professional 5-axis CNC precision machining service provider, we manufacture this marine impeller using integrated 5-axis simultaneous machining technology. This advanced process overcomes the technical challenges of complex hydrodynamic curved surfaces and thin-walled structures by completing all machining operations—including flow channels, gradually-varied blades, and hub base—in a single setup.

Utilizing dynamic tool-axis vector control technology, we achieve an exceptional surface profile accuracy of 0.02mm. Our high-speed precision milling process effectively minimizes thin-wall deformation, ensuring the final product meets G2.5 dynamic balance standards.

This impeller fully demonstrates our core competencies in:

5-axis spatial interpolation algorithms

Multi-axis coordinated machining

Aerospace-grade surface precision

The result is a mission-critical component for marine propulsion systems that delivers both superior hydrodynamic performance and structural reliability.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文