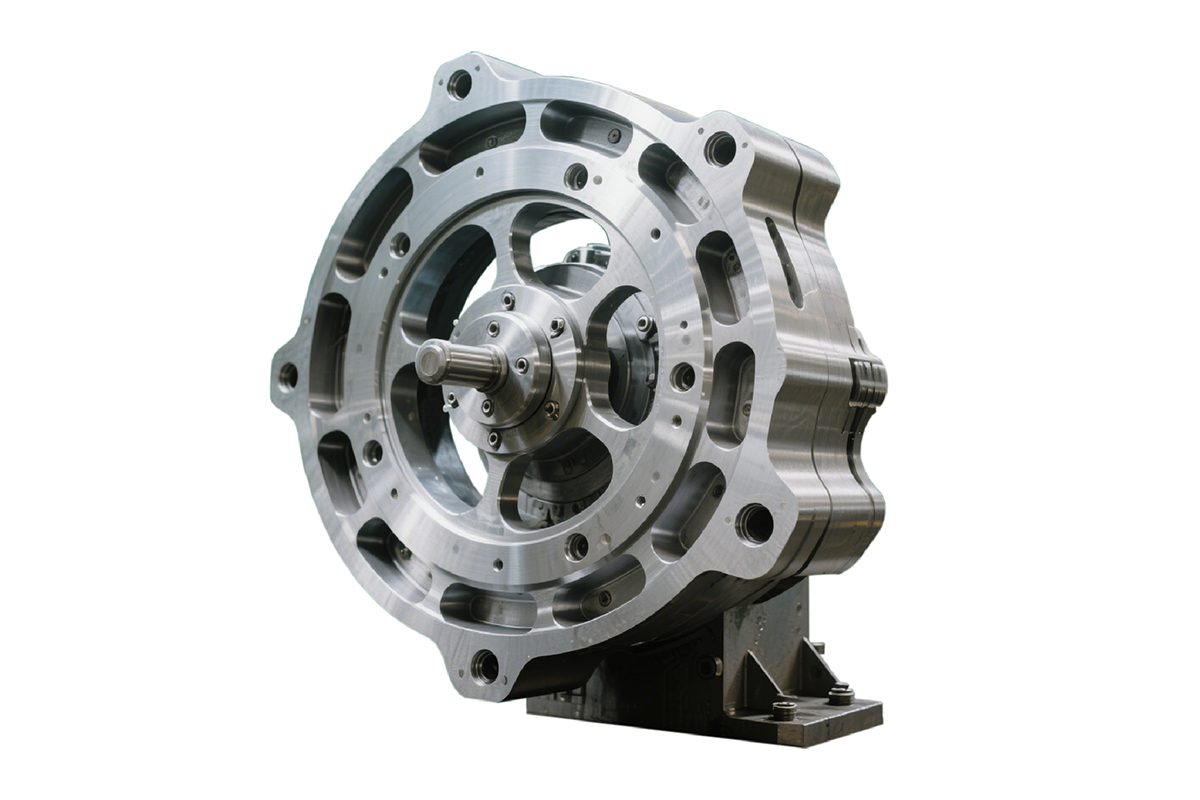

Impeller

Product Name: Impeller

Material: Titanium Alloy

Dimensions: D 850 × 280 mm

Processing Method: 5 axis cnc machining for sale

Product Features:

This product is integrally formed using high-precision 5-axis simultaneous CNC technology, specifically designed for marine fluid power systems to achieve seamless and precision machining of complex curved blades. Addressing the challenges of multi-angle twisted blades, thin-walled structures, and high-strength corrosion-resistant alloy materials, our 5-axis dynamic machining technology effectively resolves issues such as cumulative positioning errors from multi-step processes and deformation due to insufficient rigidity. It ensures an overall dimensional accuracy of ±0.02 mm, surface roughness of Ra ≤0.8 μm, and dynamic balance grade of G2.5. Through simulation-based optimization, the process achieves efficient cutting and maximizes material utilization, delivering exceptional hydraulic performance and extended service life. This highlights our core technical expertise in multi-axis machining of complex components.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文