What is Five-Axis CNC Machining?

Five-axis CNC machining refers to a process where the tool can move simultaneously in the directions of the X, Y, and Z linear axes, as well as in the A axis (rotating around the X axis) and the B axis (rotating around the Y axis). This means that the workpiece can be processed from any direction, significantly enhancing the freedom of machining and the feasibility of complex geometries.

Main Advantages of Five-Axis CNC Machining

Improve Machining Accuracy and Efficiency

Since five-axis CNC machining can complete the processing of multiple surfaces in one setup, it avoids the positioning errors caused by multiple setups, thereby significantly improving machining accuracy. At the same time, it reduces manual intervention, shortens the machining cycle, and improves production efficiency.

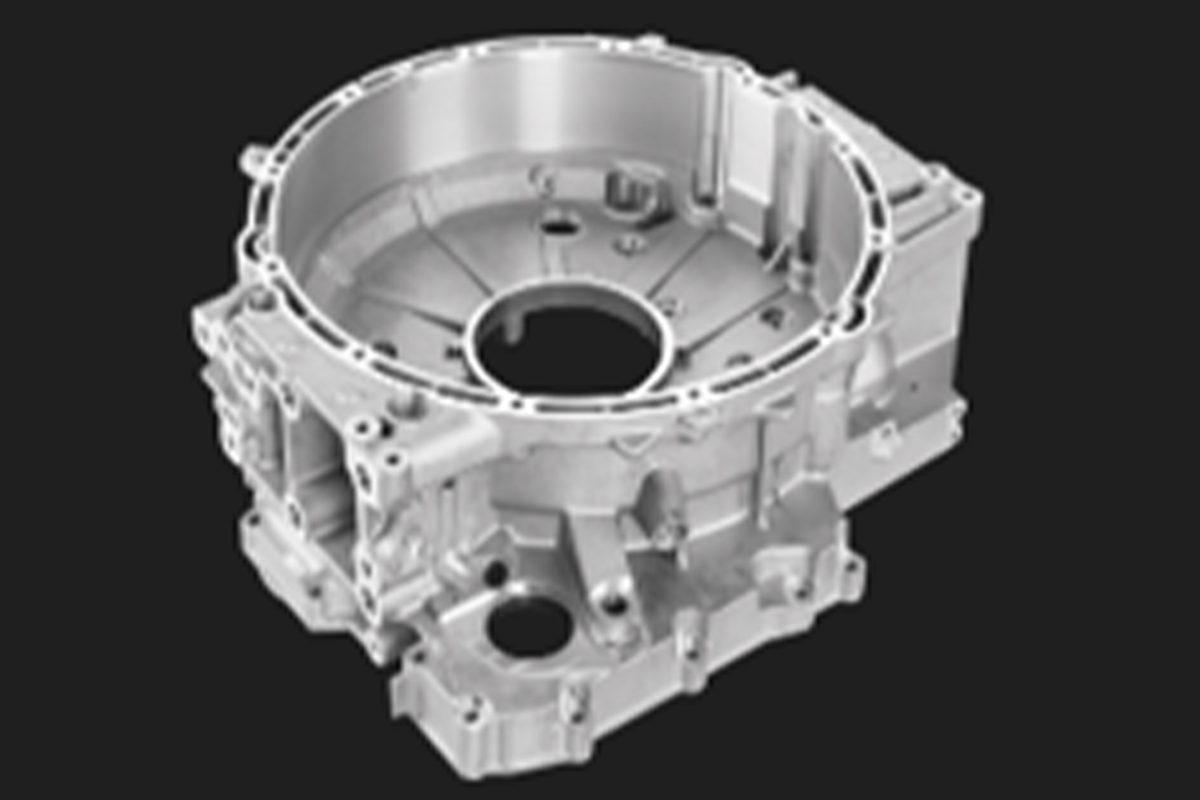

Achieve Complex Parts Machining

Complex structures such as curved surfaces, deep cavities, and inclined holes, which are difficult to handle with traditional three-axis machining, can be easily achieved with a five-axis system. For example, five-axis CNC machining is particularly important in structures like aircraft engine blades and artificial joints.

Extend Tool Life and Improve Surface Quality

In five-axis CNC machining, the tool can contact the workpiece surface at the most suitable angle, reducing cutting force, vibration, and heat accumulation, effectively extending the tool life while improving the surface finish of the machined surface.

Development Trends

In the wave of intelligent, personalized, and green development of global manufacturing, five-axis CNC machining technology is showing broader development prospects. In the future, with the further reduction of equipment costs, continuous optimization of programming software, and improvement of talent training systems, five-axis CNC machining is expected to become popular in small and medium-sized enterprises, accelerating the global layout of high-end manufacturing capabilities.

Conclusion

As an important tool in modern high-end manufacturing, five-axis CNC machining is promoting process upgrades in various industries with its unparalleled flexibility and precision. It not only enhances the capability to manufacture complex parts but also effectively optimizes the production process, reduces human dependence and error rates, and provides a solid foundation for "high precision, high efficiency, and intelligent" manufacturing.

By Leo Liao

Hi everyone, I am one of the co-founders of Zhihui Precision. You can call me Leo.

I've been in the parts machining industry for 15 years, I'm 38 years old, and now I'm a senior engineer at Zhihui Precision.

In the past 15 years of career, from the very beginning of the mechanical design apprenticeship, to bench-worker, machining process engineers, project engineers, and then to the senior engineer, all the way, has been in the machining industry inside the deep cultivating, learning a amount of rich theoretical knowledge and practical experience.

What makes me persist in this seemingly boring industry? I think it should be the love, as well as watching part process start from scratch, from the beginning of a concept to design, and then step by step to make it into a physical process, so that I have a sense of fulfilment and achievement, love and enjoyment in it, the joy will come with it.

I have a dream, that is, in their own professional life while taking care of family life can always stick to the original intention, tireless in their favourite machining industry with the attitude of craftsmanship to do a good job of every part by my hands, so that looks very textured, it smell rust, plus gorgeous surface treatment to add, the appearance and dimensions are just prefect, so that every part like a work of art in the hands of the customer.

So, what can be done to give each part the appearance and dimensions that are just perfect and present it to the customer like a work of art?

I think we're on our way, because here's what we did.

1. Upgraded factory facilities and equipment, respectively:

1.1 With a 10,000 square metres factory workshop.

1.2 50+ CNC Machining Centres and Turn-Mill Machining Centres (Vertical and Horizontal) with 40 sets of 4 & 5 Axis CNC Machining Centres.

1.3 Complete production and machining auxiliary equipment, including a flexible line with automatic loading, a complete and leading cutting tools management warehouse, a separate parts polishing department, a warehouse centre, and a production management system scientifically managed by MES and ERP.

2. Enriched team, with 100 + people, 15 people more than 10 years of 5-axis CNC programming and machining experience in the core team, 5 people experienced in foreign trade project management team.

3. Equipped with an advanced inspection system and equipment, with multiple RENISHAW inspection systems, including CMMs of ZEISS and LK, hand-held material analysers, hand-held 3D part scanners, as well as providing CT scanning measurement.

4. Improving and perfecting our company through international certifications, we are ISO9001:2015 certificated, in the process of applying for ISO13485 certification, China High-Tech Enterprise certified, and have 20 company technology patents.

5. We are still moving forward to the goal, towards refinement, lean process, and through advanced digital, automation equipment and improve the company, so that the production process is more efficient, quality is more stable, through lean process and automation continuously optimise the cost, so that customers can rest assured and satisfied.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文