When assembling machined parts, the process involves integrating components into a final product. Here’s a simplified breakdown of the key assembly contents (elements and considerations):

1. Components to Assemble

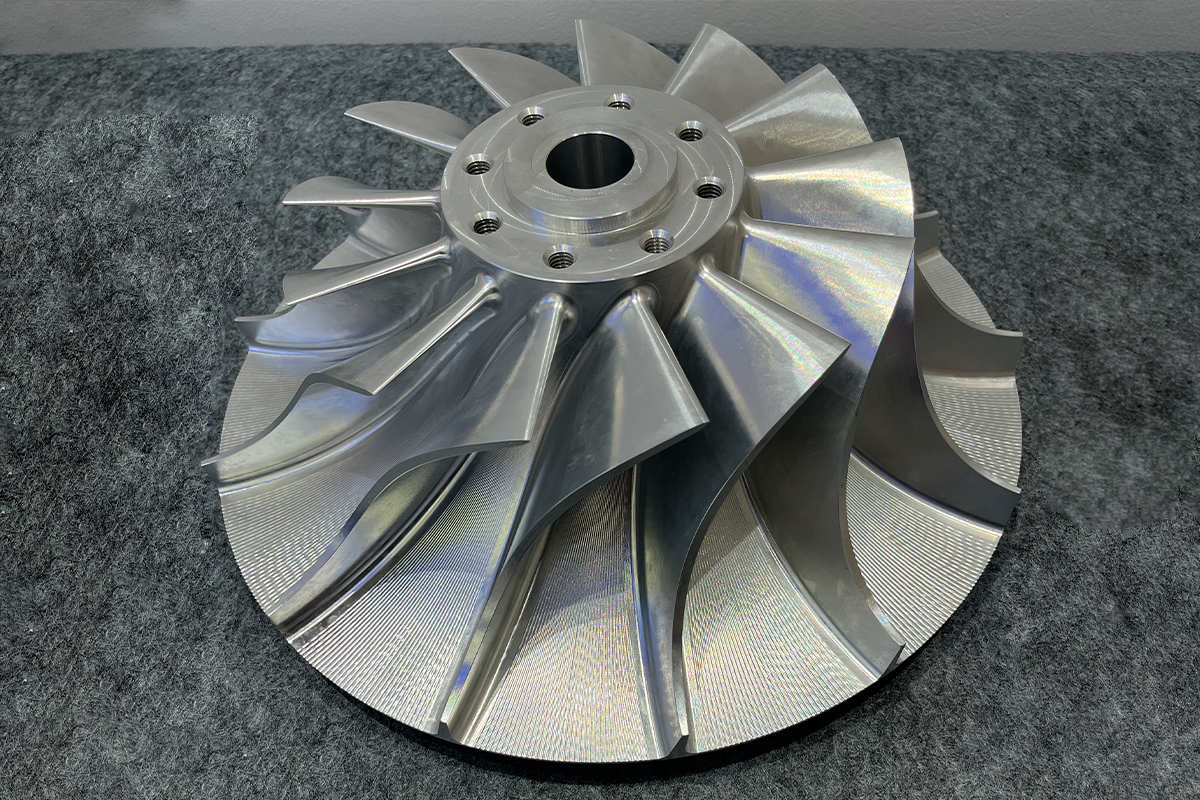

Machined parts: Precision parts produced via CNC (e.g., housings, brackets, shafts).

Fasteners: Bolts, screws, rivets, or adhesives to join parts.

Sub-assemblies: Pre-assembled units (e.g., bearings, gears, sensors).

Seals/gaskets: For waterproofing or pressure retention.

Electrical/electronic parts: Wires, connectors, PCBs (if applicable).

2. Tools & Equipment

Torque wrenches: For tightening bolts to specified values.

Presses or alignment tools: For fitting bearings/shafts.

Adhesive applicators: For epoxy or threadlocker.

Testing equipment: Multimeters, pressure testers, or alignment lasers.

3. Documentation

Assembly drawings: Step-by-step visual guides with exploded views.

Bill of Materials (BOM): List of all parts, quantities, and sources.

Torque specifications: Required tightening forces for fasteners.

Tolerance stack-up analysis: Ensures cumulative part tolerances don’t affect fit/function.

4. Quality Checks

Dimensional verification: Confirm parts fit together (e.g., pin-and-hole alignment).

Functional testing: Test moving parts (e.g., gears, actuators) for smooth operation.

Leak/pressure tests: For sealed systems (e.g., hydraulic assemblies).

Surface inspection: Check for scratches or damage during assembly.

5. Post-Assembly Requirements

Lubrication: Apply grease/oil to moving parts.

Calibration: Adjust sensors or actuators to meet performance specs.

Labeling: Add serial numbers, safety warnings, or certification marks.

Packaging: Protect finished assemblies for shipping (e.g., foam, anti-static bags).

Common Pitfalls to Avoid

Missing parts: Double-check BOM before assembly.

Over-tightening: Can strip threads or deform components.

Misalignment: Use jigs/fixtures to ensure accuracy.

Contamination: Keep work areas clean to avoid debris in assemblies.

Why It Matters

Proper assembly ensures the final product:

Works as intended: No binding, leaks, or failures.

Meets safety standards: Critical for automotive, aerospace, or medical devices.

Reduces warranty costs: Minimizes returns due to assembly errors.

By organizing parts, tools, and documentation upfront, assembly becomes efficient and error-free.

English

English