1. Machining feasibility analysis and process optimization.

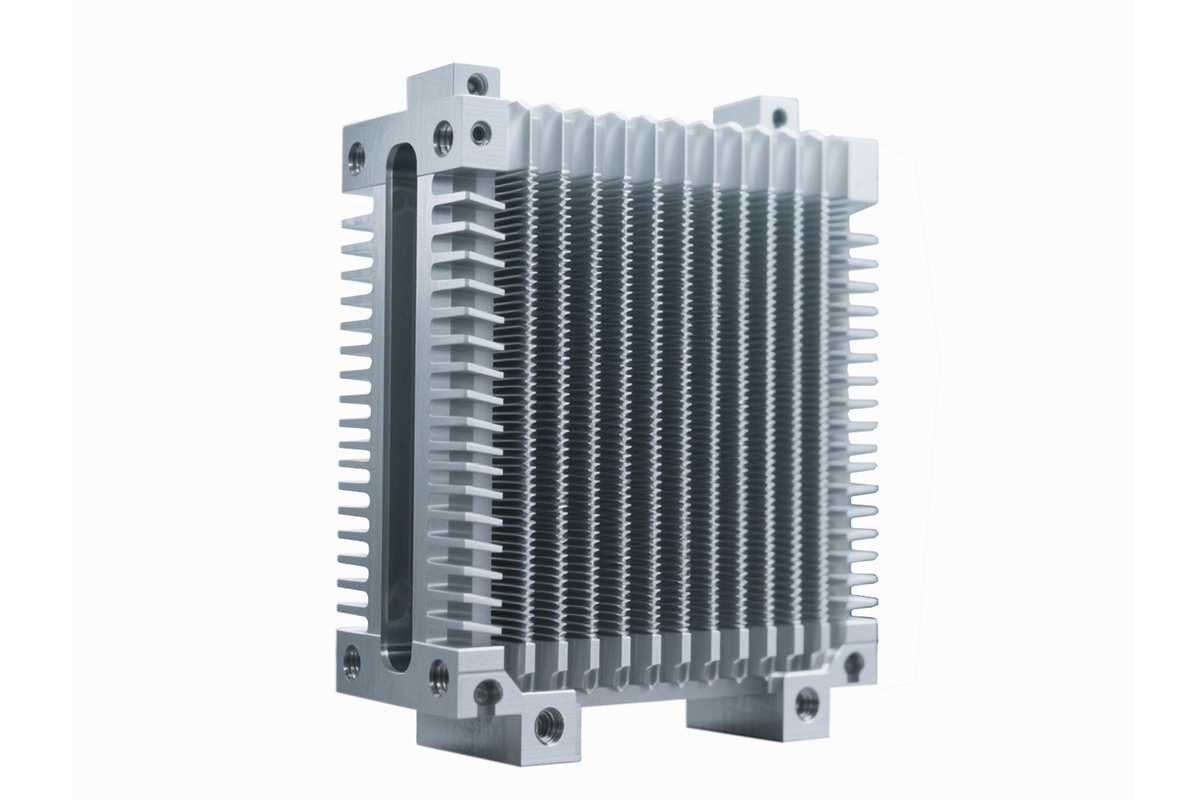

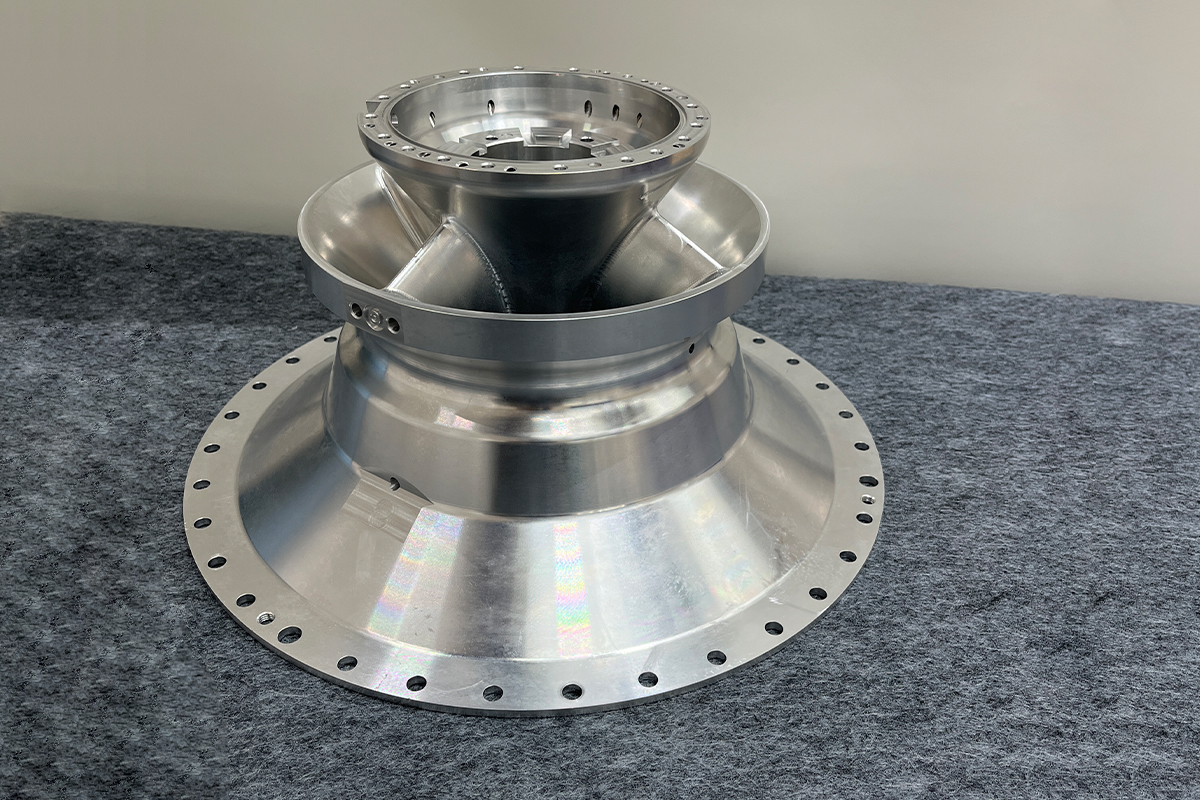

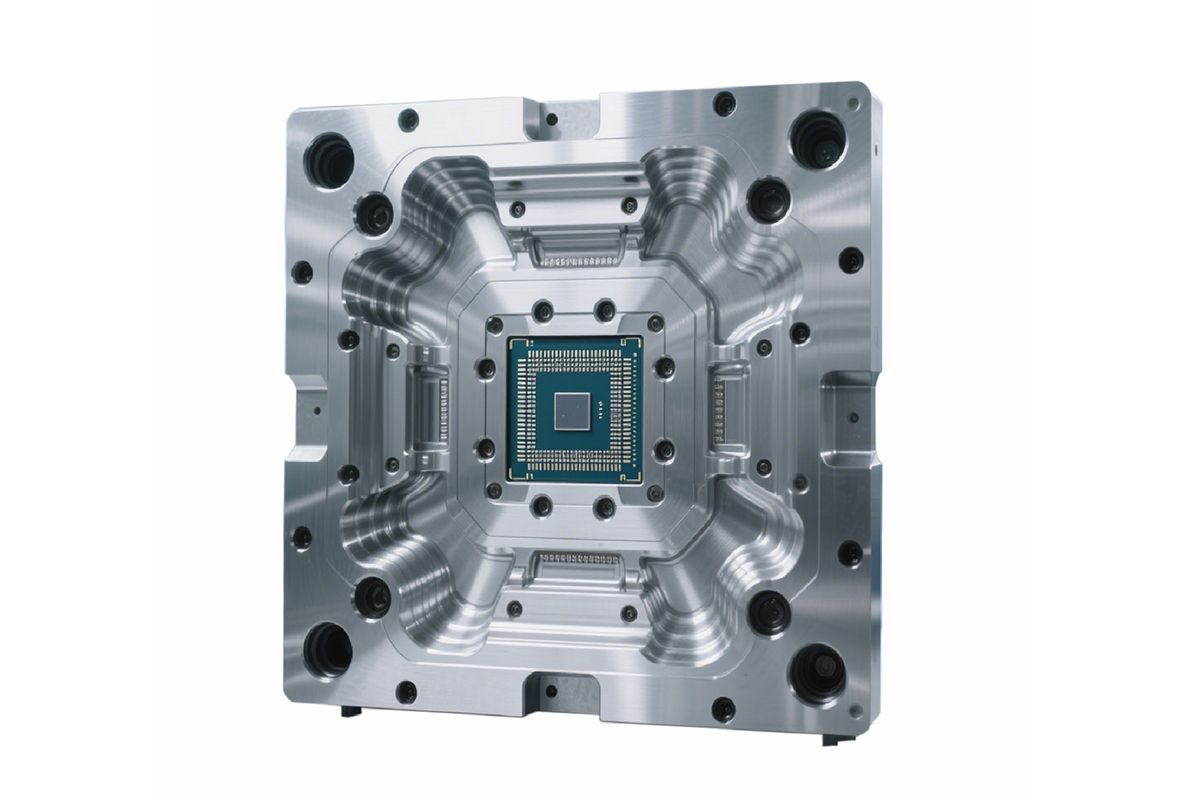

1.1 Part Structure Review: Evaluate the machining risk of complex geometric features (e.g., thin walls, deep cavities, curved surfaces) and make design optimization recommendations. For example, avoid interference and improve accuracy by reducing the number of fixtures or optimizing tool paths.

1.2 Material machinability suggestion: recommend materials suitable for 5-axis machining (e.g. titanium alloy, aluminum alloy) according to customer needs, and provide cutting parameter optimization solutions (e.g. tool coating selection, cutting force simulation).

1.3 Process route planning: design roughing, semi-finishing and finishing strategies in stages, combined with stress relief margin and layered cutting technology to ensure surface quality (e.g. Ra 0.4μm or less).

2. Fixture and clamping program design

2.1 Customized fixture development: Design multi-datum positioning fixtures for complex workpieces, e.g. vacuum chucks for thin-walled parts, five-axis linkage special fixtures to reduce the number of clamping times and improve efficiency.

2.2 Dynamic stability verification: simulate the rigidity of the fixture in high-speed machining through modal analysis to avoid the loss of precision caused by vibration.

3. Tool path planning and simulation

3.1 Five-axis linkage strategy optimization: adopt pendulum milling, side edge machining and other technologies to optimize the machining efficiency of deep cavities and complex surfaces, and carry out collision detection and path simulation through VERICUT and other software.

3.2 Intelligent parameter adjustment: AI algorithm is used to adjust machining parameters (e.g. feed speed, spindle speed) in real time to adapt to the needs of different working conditions and improve machining stability.

4. Cost and delivery cycle assessment.

4.1 Man-hour and tool consumption prediction: Based on the CAM simulation to predict the machining time, combined with the tool life model (e.g., the life of carbide tool machining titanium alloy is about 30 minutes) to provide cost optimization suggestions.

4.2 Mass production feasibility analysis: Evaluate the economics of automated production lines (e.g., robotic clamping systems) to reduce manual intervention and achieve three-shift production.

English

English