Core Advantages of Precision Hardware Parts

High Precision Matching

The greatest advantage of precision hardware parts lies in their micron-level machining tolerances, enabling tight fitting between different components, ensuring overall assembly stability and operational efficiency.

Strong Material Adaptability

Precision machining processes can be applied to a variety of high-strength or high-hardness metal materials, providing assurance for parts used in high-temperature, high-pressure, and high-corrosion environments.

Excellent Surface Treatment Capability

Through surface treatment processes such as anodizing, electroplating, sandblasting, and polishing, precision hardware parts can possess enhanced wear resistance, aesthetic appeal, and functionality, thereby improving the overall quality of the product.

Wide Application Fields

Electronics and Communication Equipment

In smartphones, laptops, and communication base stations, precision hardware parts are used for connectors, shielding cases, structural parts, etc., meeting the requirements for lightweight and high strength.

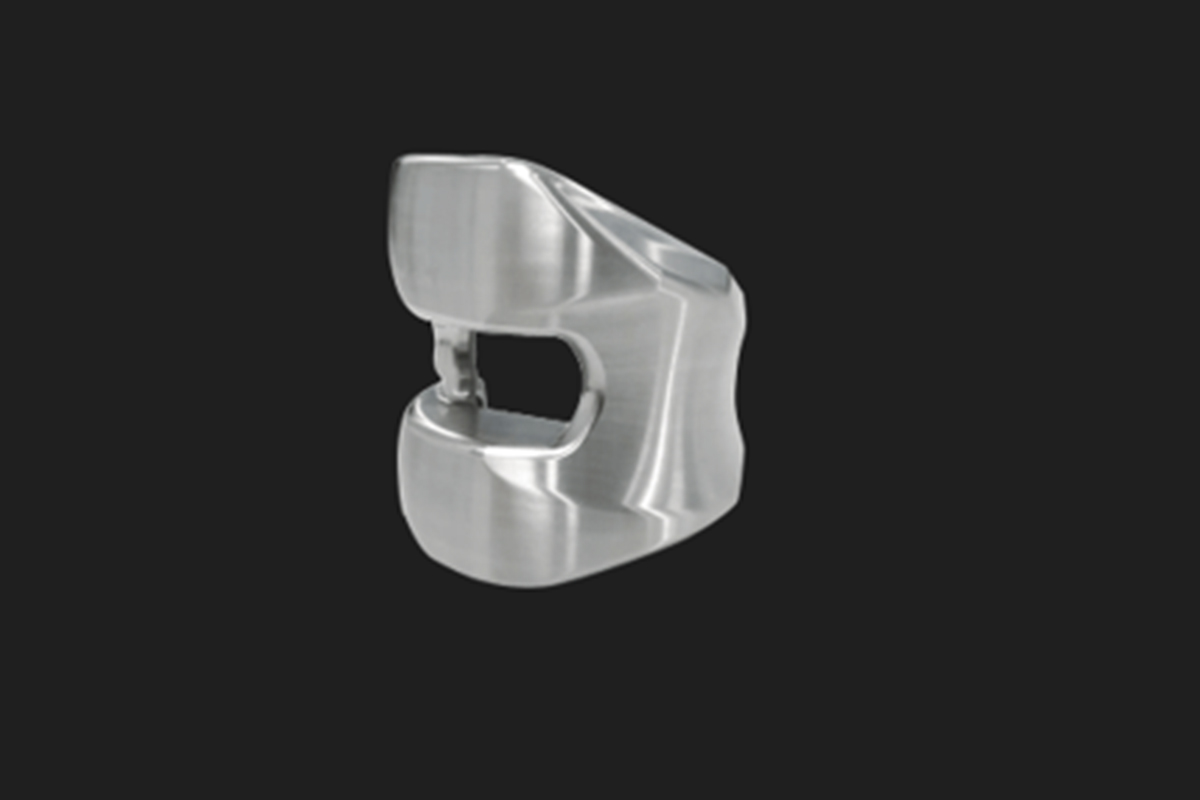

Medical Equipment

High-cleanliness, high-precision precision hardware parts are used in surgical instruments, diagnostic equipment, and implantable devices, ensuring medical safety and precise operations.

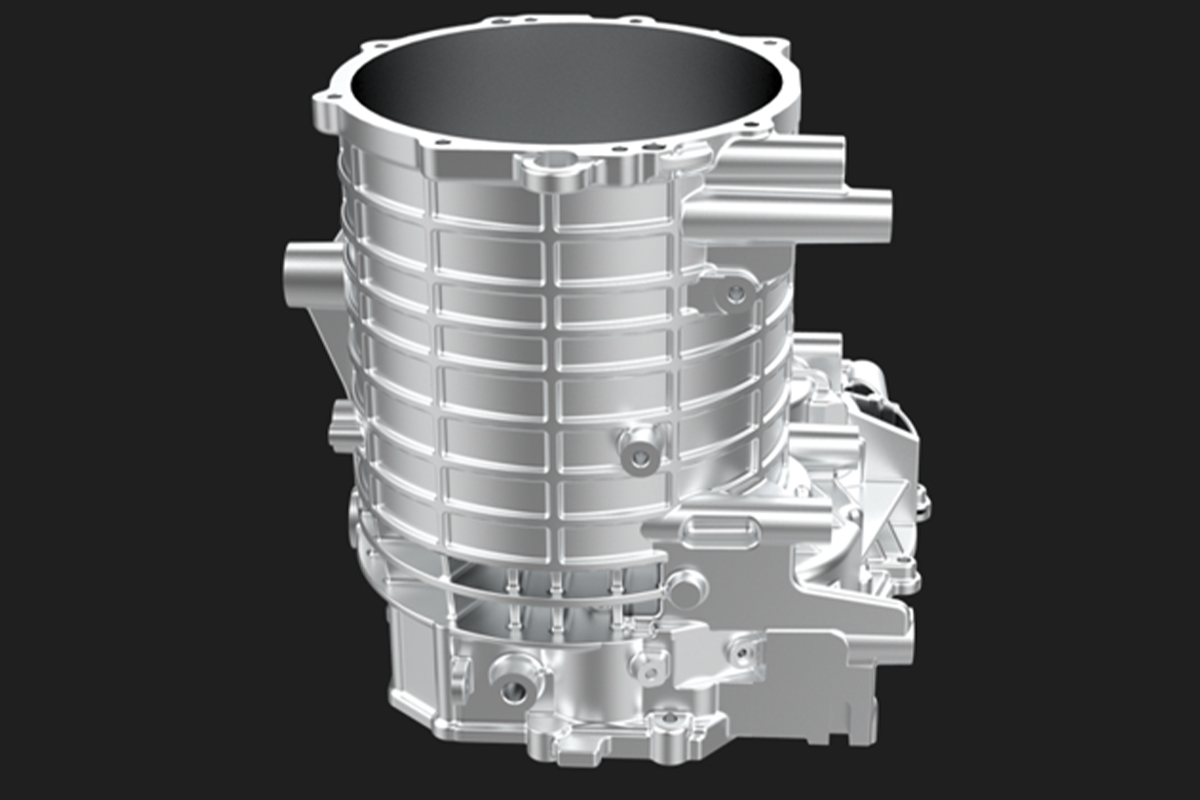

Automotive and Aerospace

From engine components and braking systems to spacecraft body connectors, precision hardware parts support the high-load operation of complex systems.

Industrial Automation Equipment

High-precision regions like robotic joints, drive shafts, and fasteners rely on stable-performance precision hardware parts to achieve efficient operation.

Development Trends and Future Prospects

With the development of smart manufacturing and Industry 4.0, the demand for precision hardware parts is evolving towards "smaller, more precise, more complex." Meanwhile, the introduction of new technologies such as 3D printing, nanoprocessing, and automated testing is driving the precision parts industry to higher levels.

In the future, precision hardware parts will continue to play key roles in strategic emerging industries such as new energy, 5G communication, biomedicine, and aerospace.

Zhihui Precision: Expert in Precision Part Manufacturing and High-Precision 5-Axis Machining

Zhihui Precision is a company specializing in the manufacturing of precision parts in aerospace, automotive, medical, and other sectors, offering high-precision 5-axis machining services to ensure the quality of every project. With a professional team and extensive experience, Zhihui Precision strictly controls each project to ensure the delivery of high-quality parts that meet customer requirements. The company serves industries including aerospace, military, automotive, medical, robotics, and automation, committed to providing customized precision parts for clients. Customers generally regard Zhihui Precision as a reliable partner, especially excelling in solving critical issues and delivering high-quality projects. To obtain services, customers can submit project requirements through Zhihui Precision's official website, and the professional team will provide personalized solutions.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文