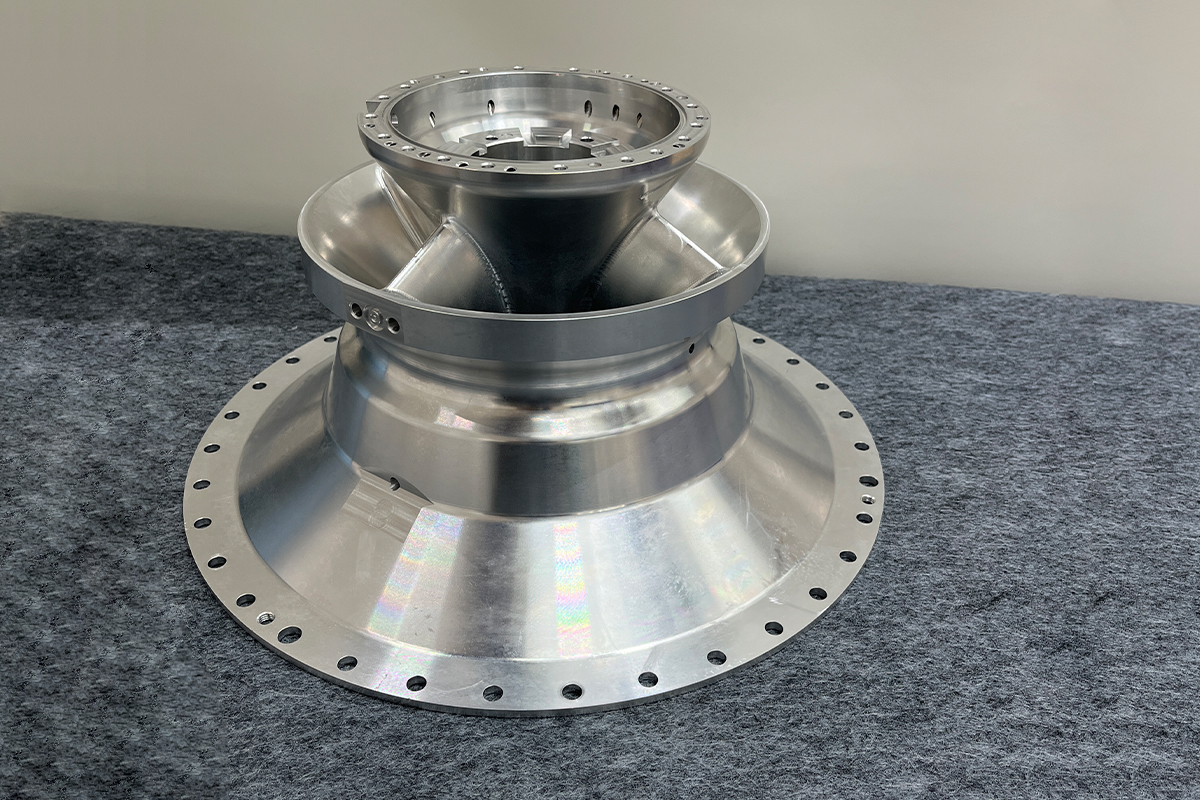

Stainless 316L

Material Properties of Stainless 316L

Surface roughness - sandblasted state | ≥ 6um |

Hardness (printing)/HRB | 93 ± 3 |

Hardness (after heat treatment)/HRB | 93 ± 3 |

Tensile strength (printed)/MPa | 700 ± 100 |

Tensile strength (after heat treatment)/MPa | 720 ± 100 |

Yield strength (printed)/MPa | 510 ± 100 |

Yield strength (after heat treatment)/MPa | 520 ± 100 |

| Elongation (printing)/% | 35 ± 10 |

| Elongation (after heat treatment)/% | 32 ± 10 |

Material Characteristics and Advantages and Disadvantages are Evaluated of Stainless 316L

Merit

316L belongs to high chromium stainless steel, which has excellent corrosion resistance, and is food grade and medical material.

Shortcoming

(1) The SLM process is prone to oxidation and requires a strict protective gas environment.

(2) Stress is generated during the forming process, making thin-walled parts susceptible to deformation.

(3) For irregular hollow parts, batch parts, threads exceeding 25, or scenarios involving CNC processes, delivery dates must be confirmed offline.

(4) During the acceleration trial run, delays in delivery may occur due to insufficient production capacity, print failures, or the time-consuming grinding of complex parts, which is considered normal.

Application Area of Stainless 316L

In the medical, food, automotive, aerospace, Marine engineering, chemical processing and other industries, it is widely used in structural components with high strength requirements and high corrosion resistance and good biocompatibility, such as high precision and customized implants, surgical instruments and prosthetics that are compatible with the human body, and machinery and components that require frequent disinfection and resistance to food acids.

English

English