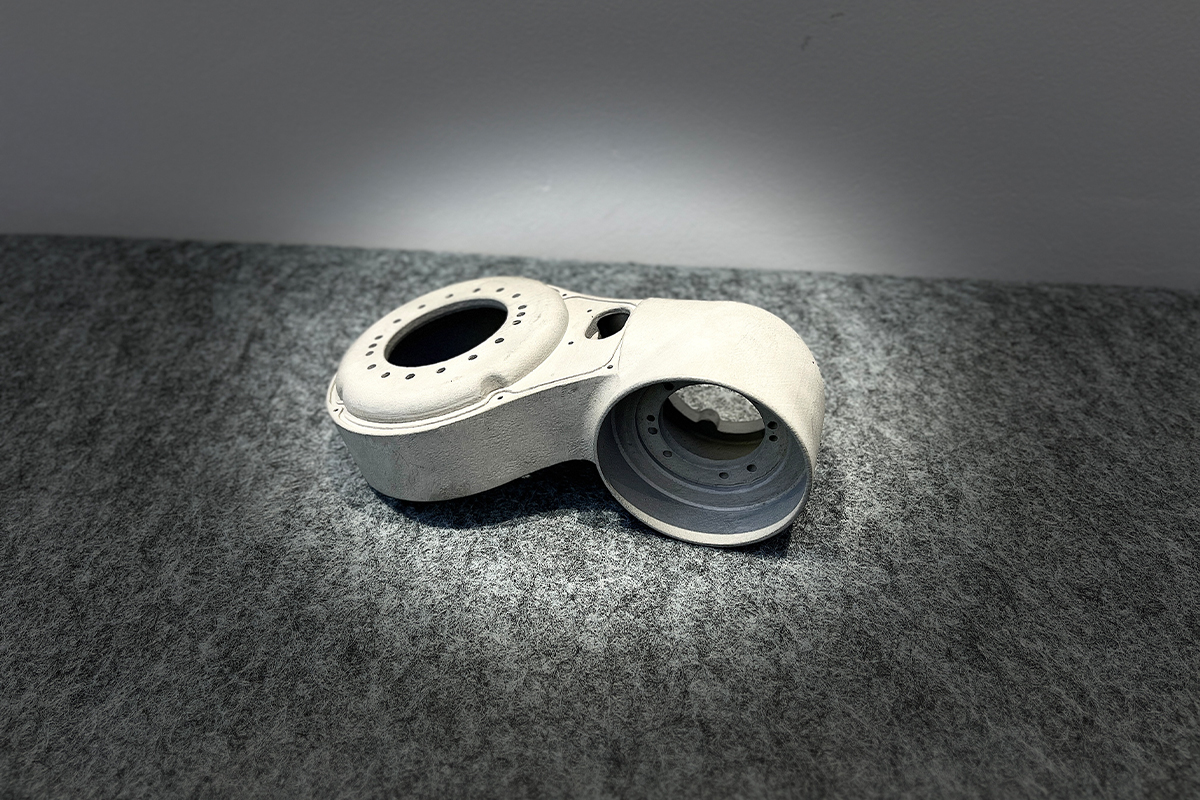

ABS

Material Properties of ABS

Hot deformation temperature | 104 ℃ |

Tensile strength | 32.5-34.1MPa |

Fracture elongation | 2.3% -3.1% |

Bending strength | 59 ± 1.3MPa |

| Simply supported beam impact strength | 12.6±1.1KJ/M² |

Material Characteristics and Disadvantages are Evaluated of ABS

Merit

The polymer material has good comprehensive performance, high impact strength, strong chemical stability and good electrical performance, can be chrome plating and spraying on the surface, and has high impact resistance and high heat resistance

Shortcoming

Due to current technological limitations, please order the following parts with caution and do not accept after-sales service caused by the following risks:

(1) Fine structures with a diameter<2mm may break or be missing;

(2) Structural surfaces with an inclination<45°, especially curved surfaces, have rougher surfaces and may deform slightly (it is recommended to choose imported materials);

(3) Large flat structures with a length> 150mm may warp or deform (it is recommended to choose imported materials);

(4) Parts with many supports will have rougher bottom support surfaces (it is recommended to choose imported materials);

(5) Complex internal structures cannot be fully removed by hand (it is recommended to choose imported materials for water-soluble supports).

English

English