Nickel-based Alloy GH4169

Material Properties of Nickel-based Alloy GH4169

Surface roughness - sandblasted state | ≥ 6um |

Hardness (printing)/HRB | 30 ± 3 |

Hardness (after heat treatment)/HRB | 45 ± 3 |

Tensile strength (printed)/MPa | 1080 ± 80 |

Tensile strength (after heat treatment)/MPa | 1400 ± 100 |

Yield strength (printed)/MPa | 770 ± 80 |

Yield strength (after heat treatment)/MPa | 1150 ± 100 |

Elongation (printing)/% | 25 ± 3 |

| Elongation (after heat treatment)/% | 18 ± 5 |

Material Characteristics and Disadvantages are Evaluated of Nickel-based Alloy GH4169

Merit

It has good comprehensive properties in the temperature range of-253~650℃. The yield strength below 650℃ ranks first among the deformation high temperature alloys, and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, as well as good processing properties and welding properties.

Shortcoming

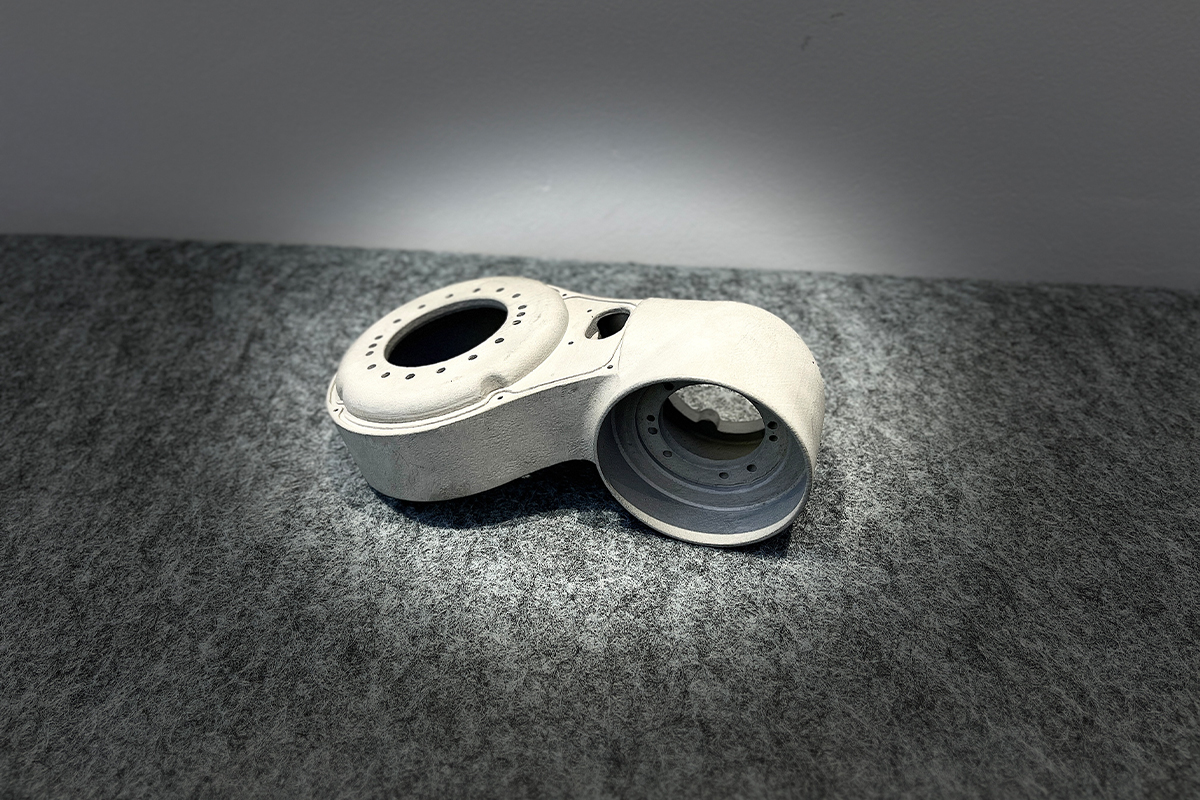

SLM (Selective Laser Melting) molding process are easy oxidation and strict protective gas environment is required. Stress will be formed during the molding process, and thin wall parts are prone to deformation. When the shape of hollow parts, batch parts, number of threads exceeds 25, CNC process is included, etc., the delivery time needs to be confirmed offline.

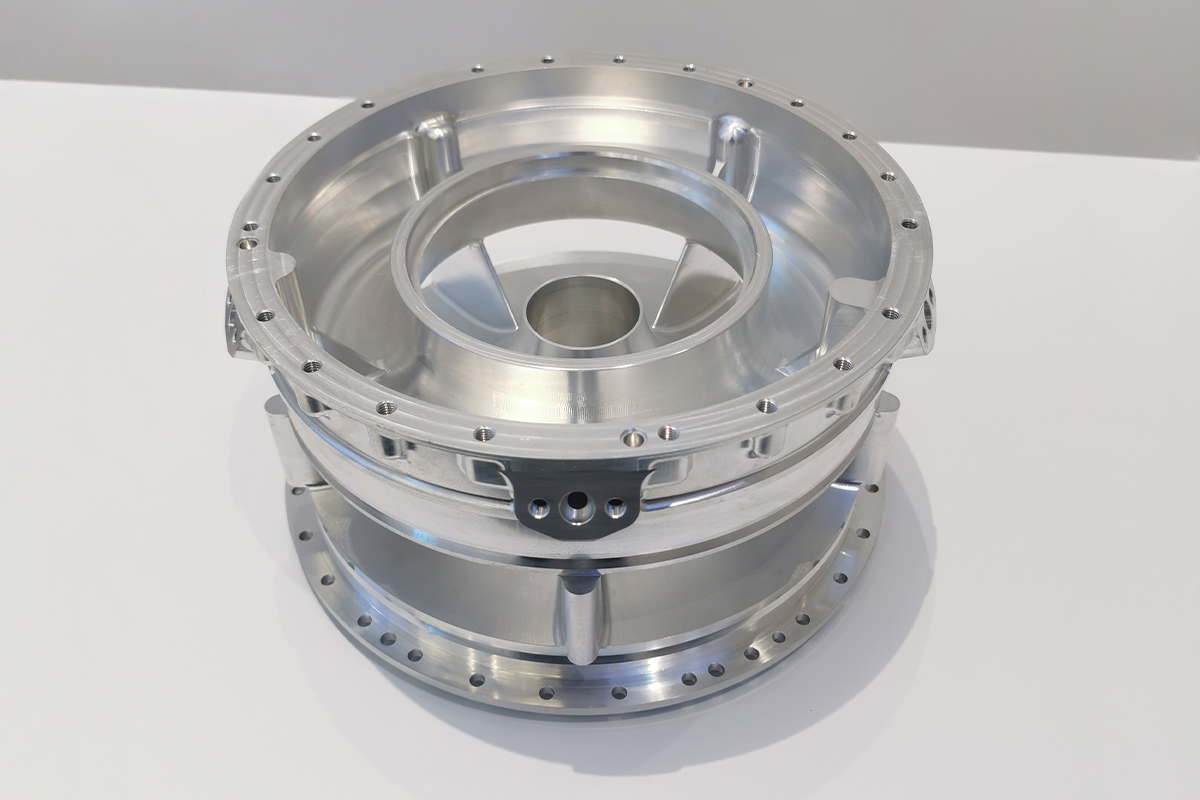

Application Area of Nickel-based Alloy GH416

Aerospace, nuclear industry, petrochemical industry are often used to manufacture gas turbine, turbine disk, combustion chamber core components.

English

English