Aluminum 6061

Material Properties of Aluminum 6061

Surface roughness-sandblasted state | ≥7um |

Hardness (printed)/HRB | 90±10 |

Hardness (after heat treatment)/HRB | 120±30 |

Tensile strength (printed)/MPa | 260±40 |

Tensile strength (after heat treatment)/MPa | 300±20 |

Yield strength (printed)/MPa | 202±40 |

| Yielding strength (after heat treatment)/MPa | 250±20 |

| Elongation (printed)/% | 14±5 |

| Elongation (after heat treatment)/% | 10± 5 |

Material Characteristics and Disadvantages are Evaluated of Aluminum 6061

Merit

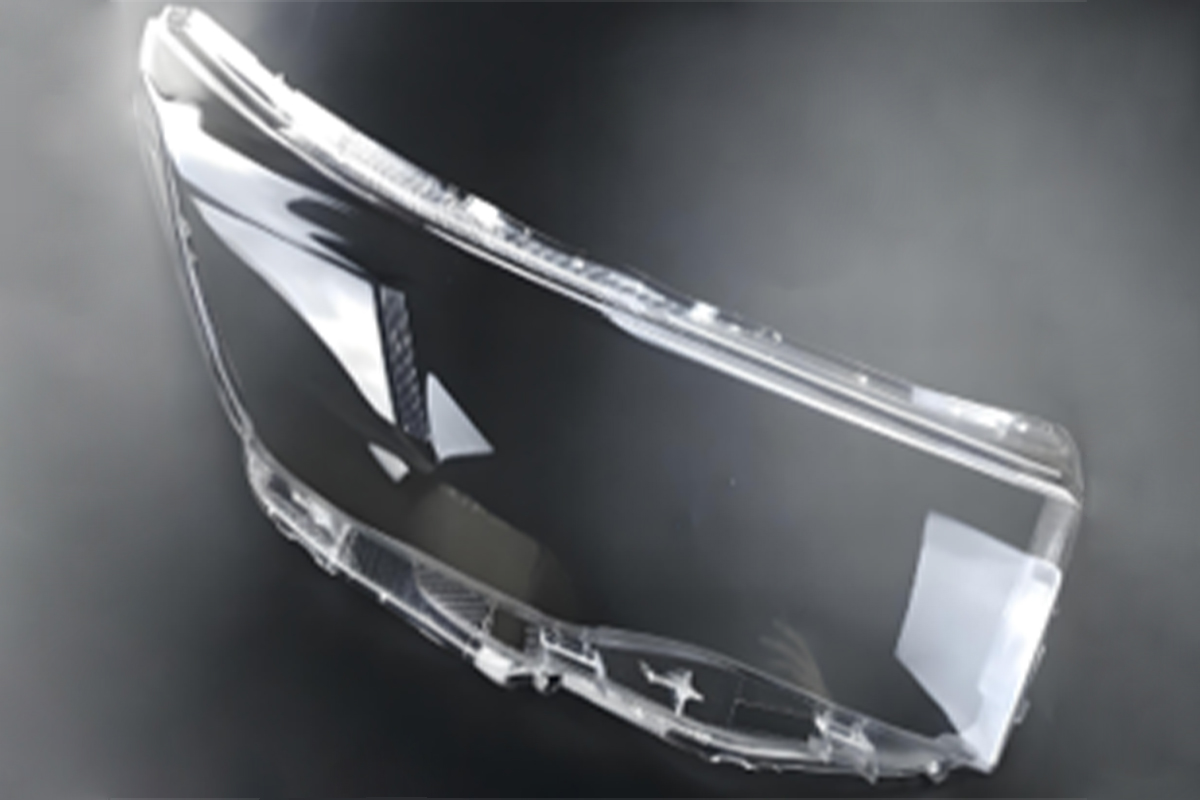

It has excellent processing performance, excellent welding and plating, good corrosion resistance, high toughness and no deformation after processing, easy polishing, coloring and oxidation and other excellent characteristics.

Shortcoming

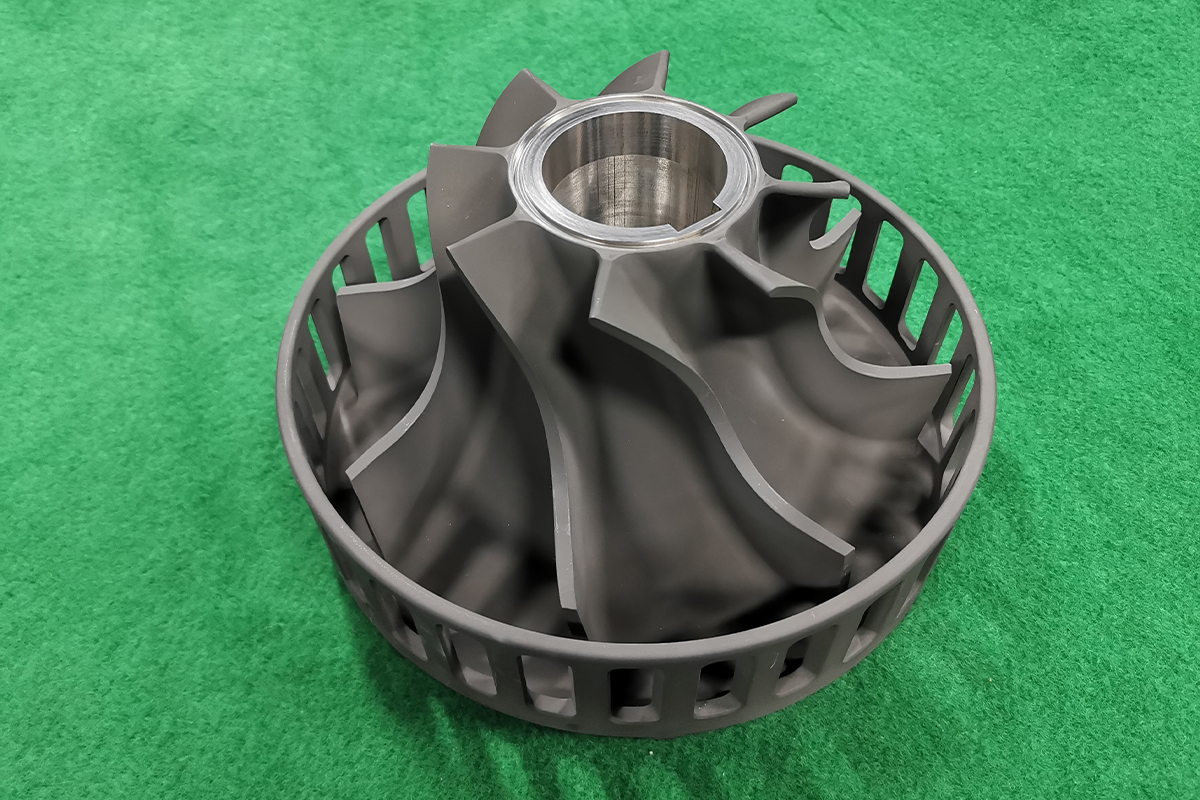

SLM (Selective Laser Melting) forming process is easy to oxidize, so it needs a strict protective gas environment. Stress will be formed during the forming process, and thin wall parts are easy to deform. When the shape is hollow, the batch size is more than 25, or CNC process is included, the delivery time needs to be confirmed offline.

Application Area of Aluminum 6061

Mechanical, automobile, aerospace and other industries are widely used in industrial structural parts with certain strength requirements and high corrosion resistance, such as truck manufacturing, tower buildings, ships, trams, railway vehicles, aerospace and so on.

English

English