Engineering

Zhihui Precision has the Engineering Capability including R&D with Early Projects Support, Design & Engineering, Materials we use, Mass Production, Assembly, Fast Delivery.

R&D with Early Projects Support

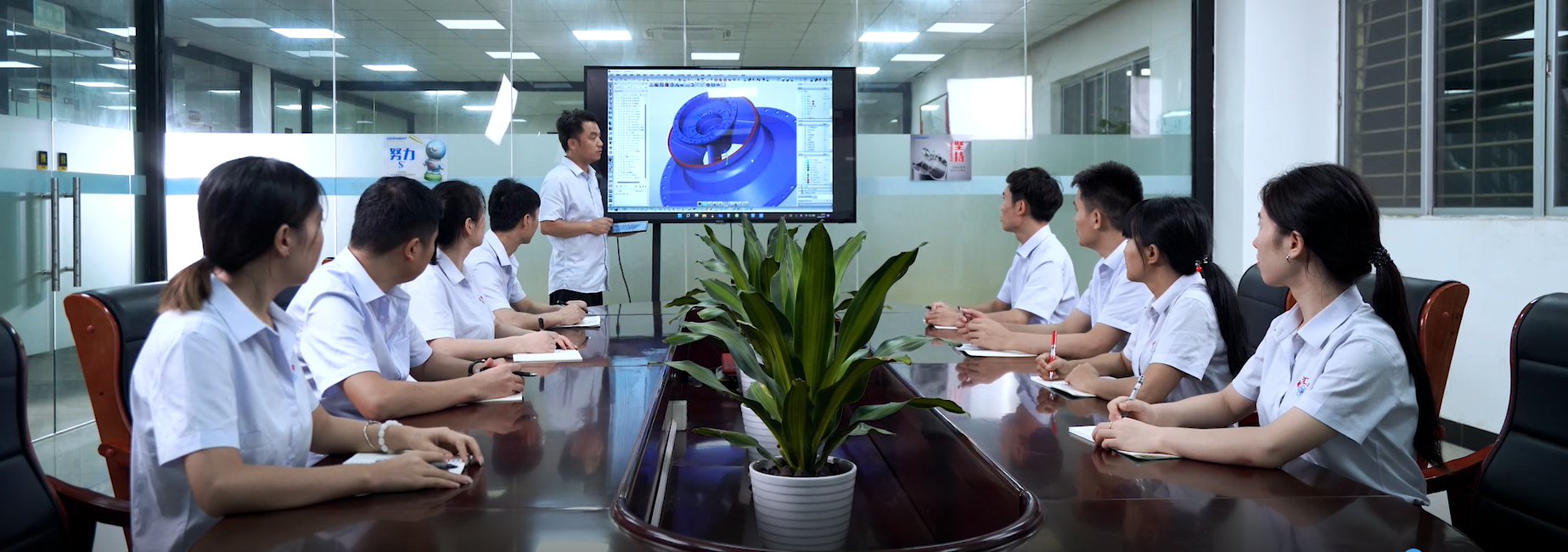

When customers promote development projects with potential intentions, we closely track the progress of the project in real time and provide our customers with professional advice and support to the best of our ability. As long as the customer puts forward the demand for support, we will do everything we can. With deep professional expertise, cutting-edge industry insights, and rich practical experience, we can quickly deploy resources to customize the optimal solution for the project and significantly shorten the development cycle. At the same time, we pinpoint and overcome all kinds of difficulties and pain points to provide a solid guarantee for the smooth progress of the project and help the project efficiently achieve the expected results.

When we receive a new project, we conduct a comprehensive and rigorous verification of its specifications and functions, and clearly define the quality requirements to set clear standards for the subsequent processing steps. Relying on our deep technical accumulation and rich experience, we analyze the feasibility of processing in-depth and consider the technical difficulties and potential challenges that may be faced in the process. Scientifically evaluate the quality achievement rate to ensure that the expected quality standard can be stably achieved in the actual production. Explore intelligent production with human-machine support and strive to maximize efficiency. At the same time, we carry out comprehensive planning for cost optimization and reasonably control the costs of raw material procurement, production and processing, and manpower input under the premise of quality assurance. From multiple dimensions, conduct an all-around and deep analysis. On this basis, further integration of all aspects of the elements, to build a complete set of parts processing program, which covers from the initial conception of engineering design, to the fine layout of process planning, to the quality control of the whole process of supervision, until the final packaging and shipment of the rigorous end. This ensures that each part can be produced according to the optimized process and delivered to the customer with high efficiency and high quality.

Key tasks for R&D and Early Projects Support

1. Machining feasibility analysis and process optimization.

1.1 Part Structure Review.

1.2 Material machinability suggestion.

1.3 Process route planning.

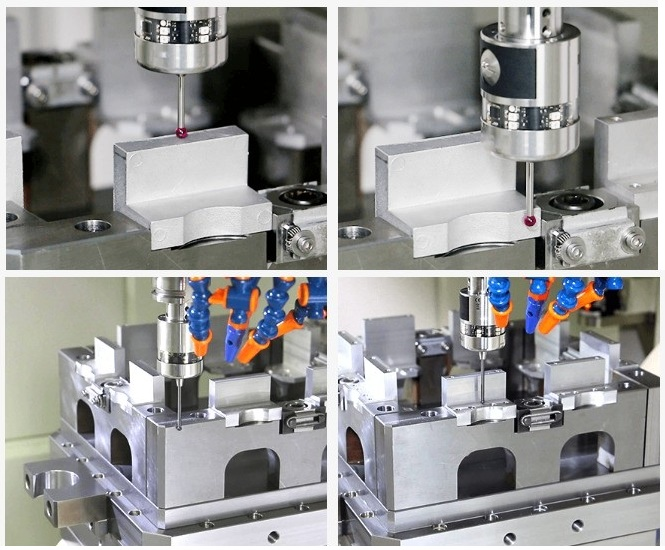

2. Fixture and clamping program design.

2.1 Customized fixture development.

2.2 Dynamic stability verification.

3. Tool path planning and simulation.

3.1 Five-axis linkage strategy optimization.

3.2 Intelligent parameter adjustment.

4. Cost and delivery cycle assessment.

4.1 Man-hours and tool consumption prediction.

4.2 Mass production feasibility analysis.

From the early R&D and design stage of our customers' products, our company will provide strong technical support. We will conduct detailed analysis on the manufacturability of the products, cost controllability for mass production, and quality reliability of the processed products, and offer effective recommendations.

Design & Engineering

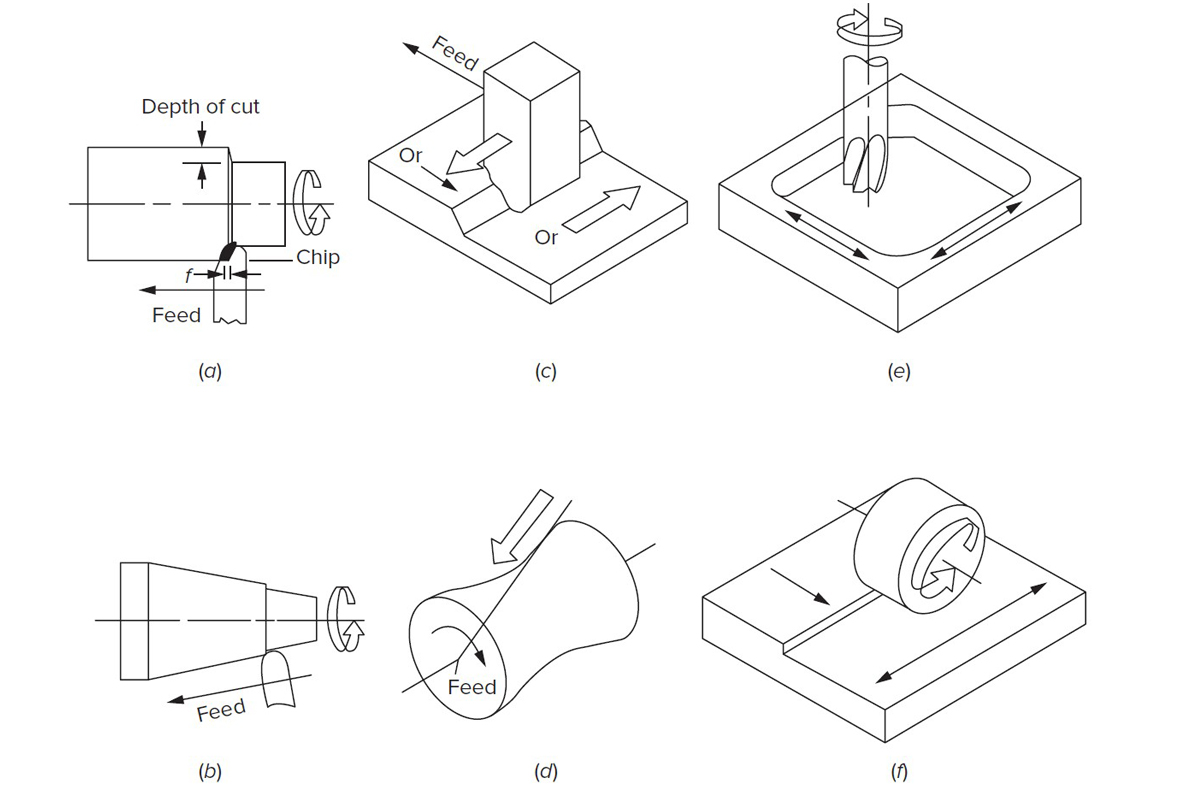

The engineering design process for precision 5-axis CNC parts machining is a structured approach that ensures high accuracy and efficiency. Here's a comprehensive breakdown:

1. Requirements Gathering & Analysis

2. Conceptual Design

3. Detailed Design

4. Simulation & Analysis

5. Toolpath Planning & Optimization

6. Setup & Fixturing

7. Machining Execution

8. Post-Processing

9. Inspection & Quality Control

10. Documentation & Handover

11. Continuous Improvement

Cross-Cutting Considerations:

By integrating these steps, the process ensures precision, reduces lead times, and balances cost-efficiency with high-quality outcomes. Collaboration between design and manufacturing teams is critical to align intent with execution.

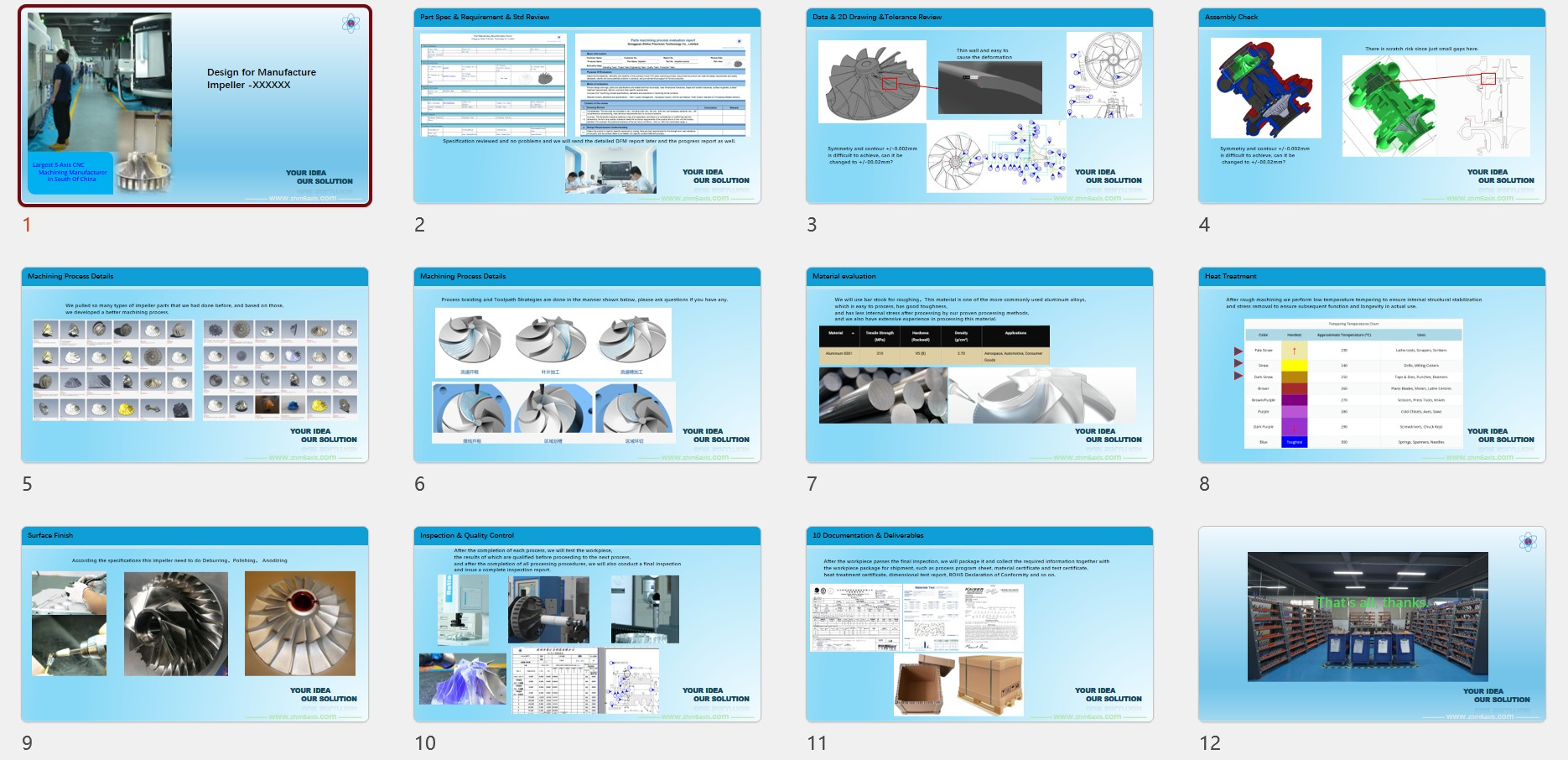

After receiving the confirmation of the order and the final processing product drawings from the customer, our company will conduct a detailed technical analysis based on the provided materials and furnish a report. We will thoroughly analyze the feasibility of processing the customer's product, the cost controllability for mass production, and the reliability of the processed product's quality. Furthermore, we will offer effective recommendations.

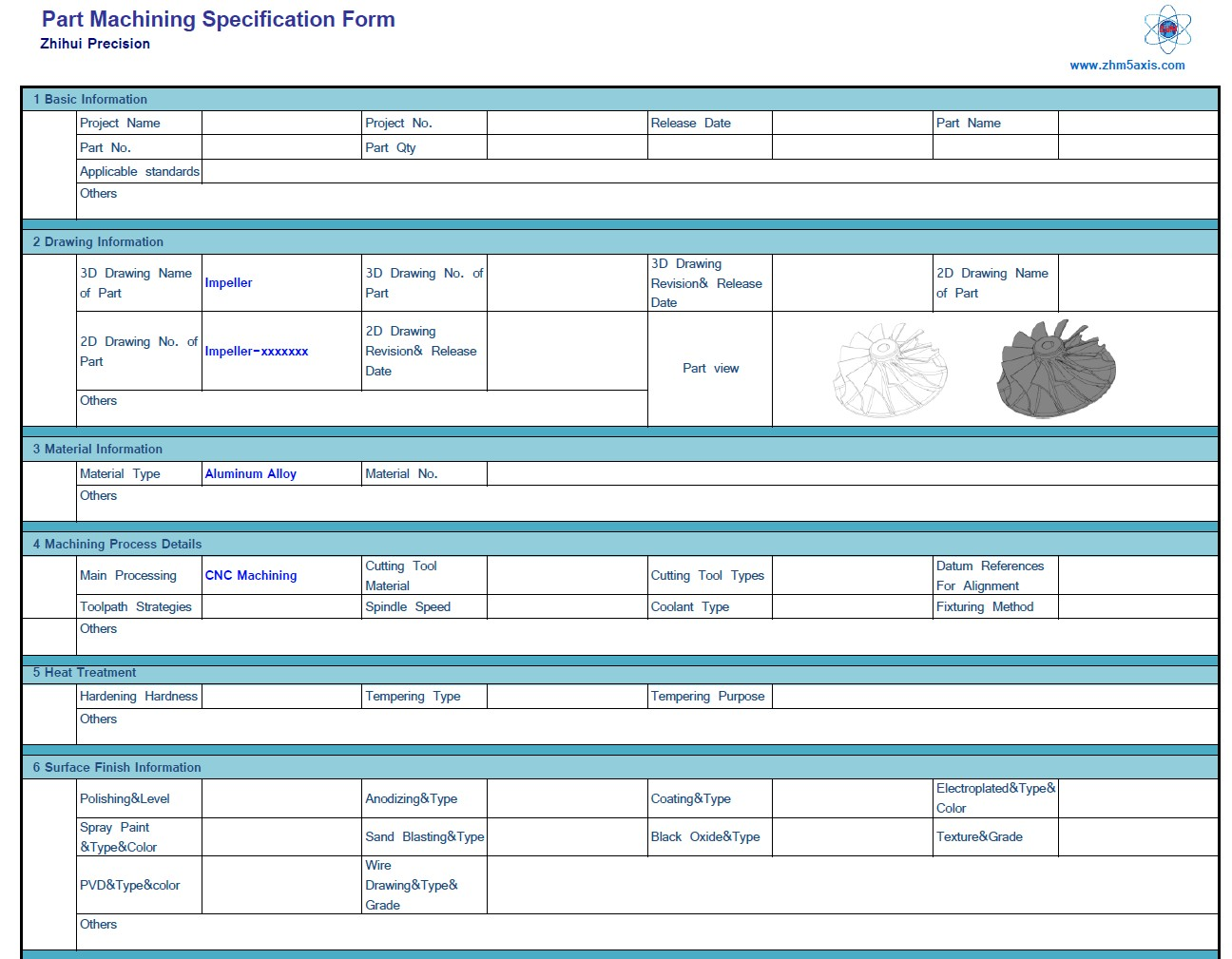

At Zhihui Precision, we dedicate our utmost attention to every product. For the machining of each item, we meticulously prepare a detailed Parts Manufacturing Specification Form (PMSF), accompanied by both 3D and 2D drawings of the product. This standardized input not only saves communication time and reduces the error rate but also streamlines the process, thereby providing a solid foundation for ensuring efficient output.

In order to determine in advance the feasibility, rationality and reliability of the parts processing technology, to ensure that the product can meet the design requirements and quality standards, we will also be on the processing of each precision parts according to the parts machining processing evaluation report(PMPER) for pre-processing review, in advance of the identification and resolution of potential problems for the formal production to provide technical support.

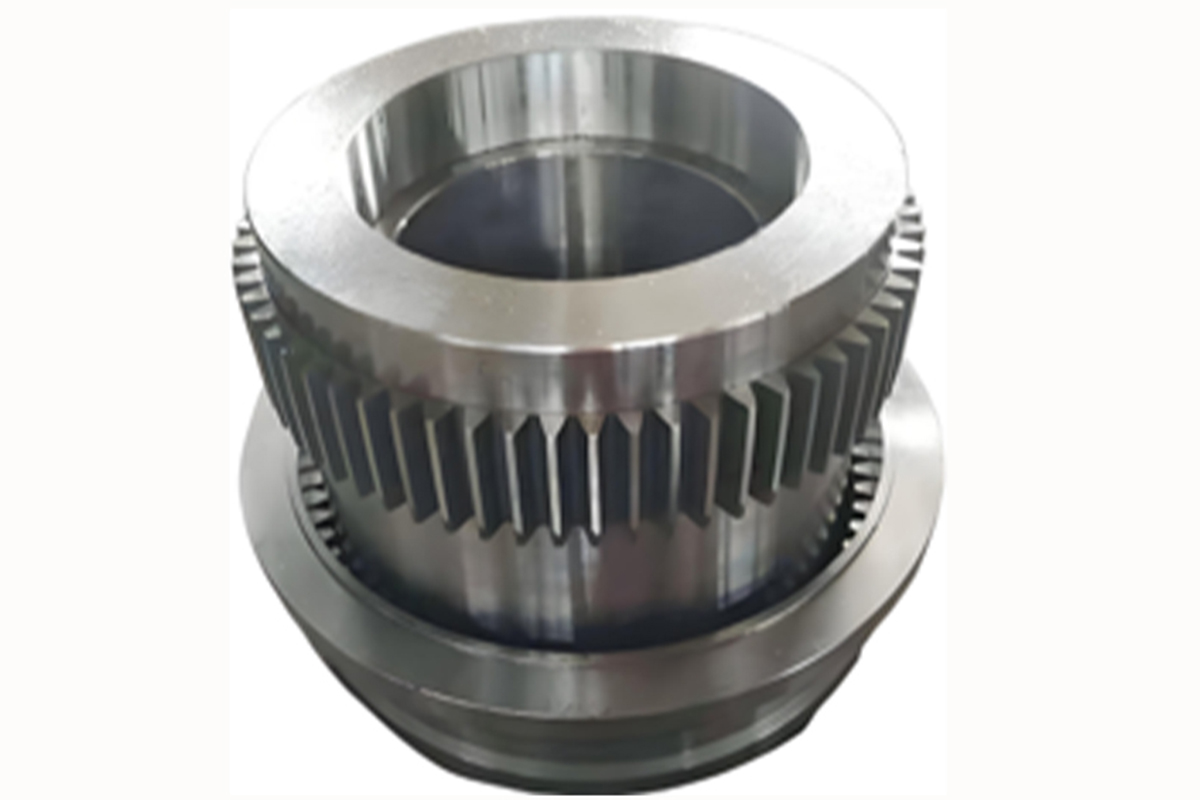

Mass Production

In today's highly competitive manufacturing environment, mass production requires not only efficient equipment and technology but also reliable partners. With its extensive equipment scale, experienced team, and mature production system, Zhihui Precision is committed to providing customers with stable, high-quality mass production services, making us your trusted manufacturing partner.

1. Extensive Equipment Scale to Meet Diverse Needs

2. Experienced Team Ensuring Production Excellence

3. Mature Manufacturing System Ensuring Stable Delivery

4. High-Quality Output Earning Customer Trust

5. Customized Services to Meet Individual Needs

6. Continuous Innovation Leading Industry Trends

Choosing Zhihui Precision means selecting a reliable, efficient, and innovative partner. With our powerful equipment resources, professional team, and mature management system, we will provide strong support for your mass production needs, helping you stand out in the competitive market.

Reduced setups: Complex parts are machined in a single setup, minimizing human error and cycle time.

Higher accuracy: Simultaneous 5-axis machining maintains tighter tolerances (±0.005 mm or better).

Material savings: Near-net-shape machining reduces waste.

Scalability: Automated workflows allow seamless scaling from hundreds to thousands of parts.

Comparison: 5-Axis vs. 3-Axis for Mass Production;

Factor: 5-Axis CNC; 3-Axis CNC;

Setup time: Minimal (single setup); Multiple setups required;

Complex geometries: Ideal (e.g., aerospace impellers); Limited (requires manual repositioning);

Cycle time: Shorter (simultaneous machining); Longer (sequential operations);

Tool access: Better for undercuts/angled features; Restricted;

Cost per part is Lower at scale (reduced labor/machines); Higher for complex parts.

Example: Mass-Producing Aerospace Turbine Blades

Material: Inconel 718.

Process:

Roughing with carbide end mills at 10,000 RPM.

Finish machining with diamond-coated tools.

In-process probing to check airfoil profiles.

Automated deburring and shot peening.

Output: 500+ blades per week with <0.01 mm profile tolerance.

Critical Challenges in Mass Production

Tooling costs: High initial investment in specialized tools/automation.

Thermal management: Heat buildup in long runs affects accuracy (compensate with coolant or machine thermal stabilization).

Workholding: Fixtures must withstand high cutting forces without deflection.

Cross-Cutting Considerations

Sustainability: Recycle metal chips, use eco-friendly coolants, and optimize energy consumption.

Cost trade-offs: Balance tighter tolerances with scrap rates and tool wear.

Operator training: Skilled technicians are needed to manage automation and troubleshoot.

By integrating advanced 5-axis CNC machining with automation, smart monitoring, and lean workflows, manufacturers can achieve high-volume production of precision parts while maintaining quality and competitiveness.

The mass production process for 5-axis CNC machining involves scaling precision manufacturing while maintaining high efficiency, repeatability, and cost-effectiveness. Unlike prototyping or small-batch production, mass production requires optimized workflows, automation, and rigorous quality control.

Here's a detailed breakdown of the key steps and considerations:

1. Design for Manufacturability (DFM)

2. Material Preparation

3. Process Planning & Toolpath Optimization

4. Fixturing & Setup Automation

5. Machining Execution

6. In-Process Quality Control

7. Post-Processing Automation

8. Final Inspection & Packaging

9. Documentation & Traceability

10. Continuous Improvement

To obtain efficient and fast machining of small-lot 5-axis precision parts, we purchased the JDFMS automated flexible production system from Beijing Jingdiao Company, which provides a guarantee for the machining of small-lot precision parts. The automation unit based on JINGDlAO high-speed machining center deeply integrates the JDFMS material handling system, reduces the dependence on labor for material transfer in the production process, realizes automatic loading and unloading, ensures the timeliness and accuracy of production factor supply, and meets the continuous machining needs of the night shift.

JDFMS flexible manufacturing system is a production system for multi-species and small-lot product processing with Jingdiao's high-speed machining centers as the core and the deep integration of automatic material supply modules. Relying on Jingdiao's mature processing equipment and application technology, it effectively reduces the dependence on manual operation for material transfer in the production link, and it guarantees the timeliness and accuracy of the supply of production elements and provides customers with a safe, stable, and continuous flexible manufacturing experience.

Assembly

Zhihui Precision can provide comprehensive assembly inspection and testing services before product shipment, effectively reducing the risk of assembly anomalies caused by design issues, thereby offering solid assurance for your project timeline.

When assembling machined parts, the process involves integrating components into a final product. Here's a simplified breakdown of the key assembly contents (elements and considerations):

1. Components to Assemble

2. Tools & Equipment

3. Documentation

4. Quality Checks

5. Post-Assembly Requirements

Fast Delivery

To achieve the goal of fast delivery, we have built up a set of complete and efficient operation system.

At the supply chain level, our strategic cooperative suppliers, who have been working with us for many years, ensure the smooth operation of every link. At the same time, the mature and advanced supply chain management system, from raw material procurement, parts supply to finished product distribution, the whole process to realizes precise control and efficient deployment.

In terms of the technical team, we have a group of like-minded colleagues and partners who have a deep technical background, all of them dare to fight, and never retreat in the face of technical problems. During more than 10 years of working side by side, we have a clear division of labor, and with the tacit understanding formed by long-term bonding and common values, we have injected a constant momentum for project promotion.

In terms of internal process management, mature internal processes and documentation systems provide solid support for business operations. Process design adheres to the principles of efficiency, simplicity, and standardization, and we also conduct regular comprehensive reviews to update the relevant documents and processes according to the ever-changing market dynamics and the individual needs of our customers, to achieve real-time updates and adaptations. The advanced MES system, as a powerful engine of digital management, is deeply integrated into all aspects of production and operation, and through real-time data collection and analysis, it provides precise navigation for efficient internal operation and ensures that the rhythm of production is well-organized.

In addition, large-scale, diversified hardware equipment at the forefront of the industry constitutes a solid foundation, from production and processing to quality inspection, building a solid foundation for product quality and delivery speed in all aspects.

Because of this, we can confidently promise our customers: you only need to be frank with the ideas and needs, rest assured that the project entrusted to us. We will take over all the subsequent work from program planning, implementation, to delivery of the finished product. You can rest assured that you can arrange their own schedule, to be completed successfully we look forward to your acceptance of the results of the project.

Achieving fast delivery for 5-axis CNC precision parts requires a combination of strategic planning, process optimization, and collaboration. Here’s a step-by-step guide to meet tight deadlines without compromising quality:

1. Optimize Design for Speed

2. Streamline Pre-Production

3. Accelerate Machining

4. Automate Workflows

5. Prioritize Supplier & Shop Selection

6. Integrate Quality Control Early

7. Fast-Track Post-Processing

8. Improve Logistics

9. Communication & Documentation

10. Mitigate Risks

Materials We Use

As the function and appearance of products are becoming more and more diversified, the materials used for parts have also been diversified, and new processes and materials are constantly being developed and challenged. In the past, we have used the following types of materials, which are still being updated and enriched, and our material suppliers, who have been steadily and quietly supporting us, are also expanding our possibilities of using new materials. Commonly used materials include: aluminum alloys, various types of steel (cast iron, alloy steel, stainless steel, spring steel, tool steel, etc.), copper alloys (bronze, brass, red copper, beryllium copper, etc.), titanium alloys, nickel alloys, magnesium alloys, glass, ceramics, and various types of plastics. Details of raw materials are shown in the table below.

| Your choices are | Material picture view | Introduction of materials & applications |

| Aluminum Alloy |

| Aluminum alloy is an alloy based on aluminum and a certain amount of other alloying elements, and it is one of the light metal materials. Aluminum is a metal with low strength and good plasticity. Except for some pure aluminum, it is made into an alloy to improve the strength or comprehensive performance, It has good casting performance and plastic processing performance, and good electrical conductivity. Thermal conductivity, good corrosion resistance, and weldability can be used as structural materials, and have a wide range of applications in aerospace, aviation, transportation, construction, electromechanical, light, and daily necessities. |

| Brass Alloy |

| Brass, by definition, is an alloy of copper and zinc. If it is composed of these two types, it is ordinary brass, but if it is composed of these two other elements, it is Special brass. Brass provides good strength, excellent high-temperature ductility and reasonable cold ductility, good conductivity, excellent corrosion resistance, good bearing properties, and low magnetic permeability. |

| Bronze Alloy |

| Bronze is a versatile alloy used in a diverse range of applications. It is synonymous with high corrosion resistance and high friction resistance against dissimilar metals. Typical applications include springs, bushes, and bearings. Bronze bars are prevalent in marine applications, including shipping and the offshore sector. Their anti-microbial properties make them ideal for use in hospitals. |

| Cast Iron |

| Cast Iron Bars are a family of engineered cast iron bar products that are designed to offer the best combination of machinability, sliding wear resistance, heat treat response, noise and vibration damping, and guaranteed mechanical properties when compared to most other as-rolled ferrous materials. Applications include shafts, sprockets, bushings, gears, molds, and more. |

| Copper |

| Copper is a common reddish metallic element that is ductile and malleable, and one of the best conductors of heat and electricity. Copper alloys are specified for services where superior corrosion resistance, electrical conductivity, and good bearing surface qualities are desired. It is widely used in electronics, energy, petrochemicals, transportation, machinery, metallurgy, light, and other new industries, and some high-tech fields. |

| Glass |

| Glass is a hard, brittle material consisting of a mixture of silicates. It is usually transparent or translucent. Glass is considered to be a cooled liquid rather than a true solid. The CNC machining process utilizes advanced CNC machines to shape, drill, and cut glass with high precision. The ability to CNC machine glass opens up various applications in industries requiring detailed and precise glass components, such as in optics, electronics, and decorative arts. |

| Glass Ceramics |

| Glass ceramics are ceramics that can be fused and then molded, formed, ground, or machined using conventional glass fabrication techniques. After part fabrication, the glass ceramic's structure is transformed from an amorphous glassy state to a crystalline ceramic state. |

| Hardened Metals |

| Metals such as tool steel are hardened before machining. Hardening of metals is a metallurgical metalworking process used to increase the hardness of a metal. Strength and hardness are different material properties. Because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation, or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness. |

| Nickel / Nickel Alloys |

| Nickel, as an important industrial metal, is widely used in steel, alloys, electroplating, batteries, magnetic materials and other fields due to its excellent mechanical strength, ductility, magnetism, and high chemical stability, high mechanical strength, which allows it to withstand heavy loads and long periods of operation. High corrosion resistance under a wide range of conditions, including high temperatures, aggressive media, and water. Nickel and its alloys find extensive use in various industries, including aerospace, chemical processing, electronics, and power generation. |

| Stainless Steel |

| Stainless steel, also known as inox or corrosion-resistant steel, is an iron-based alloy that contains a minimum of 10% chromium, which imparts remarkable resistance to rusting and corrosion. It is widely used in various applications due to its durability, aesthetic appeal, and resistance to heat and staining. Stainless steel is commonly found in kitchenware, medical instruments, and construction materials, making it a versatile choice in many industries. Stainless steel is widely used in various applications across different industries, including: Construction, Aerospace, Medical Technology, Food and Beverage, and Transportation. |

| Steel / Steel Alloys |

| Steel alloys are types of steel that are alloyed with various elements to enhance their mechanical properties. They are categorized into low alloy and high alloy steels, with the distinction based on the amount of alloying elements present. The addition of these elements improves strength, hardness, toughness, and wear resistance, making alloy steels more robust than standard carbon steels. From building structures to precision medical equipment, from energy production to high-tech electronics, alloy steel plays an indispensable role. |

| Titanium |

| Titanium is a hard, lustrous, silvery element that is relatively abundant in the Earth's crust. It is known for its lightness, strength, and corrosion resistance. For this reason, it is used widely in the aerospace industry and the medical field (e.g., replacement joints). When alloyed with other metals, especially steel, titanium adds strength and oxidation resistance. |

| Plastics |  | Plastics are any of various organic compounds produced by polymerization. They are capable of being molded, extruded, cast into various shapes and films, or drawn into filaments and used as textile fibers. Applications included housing, toys, covers, gears, prototypes, etc. |

| Rubber |  | Rubber is any of numerous synthetic elastic materials of varying chemical composition with properties similar to those of natural rubber. Applications included seal parts, toys, prototypes, etc. |

| Wood |  | Wood comes from trees and can be cut and dried, especially for use as a building material or fuel. Applications included toys, prototypes, etc. |

| Others |  | Other unlisted, specialized, or proprietary material. |

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文