-

Introduction to the Basic Situation of Surface Finishing

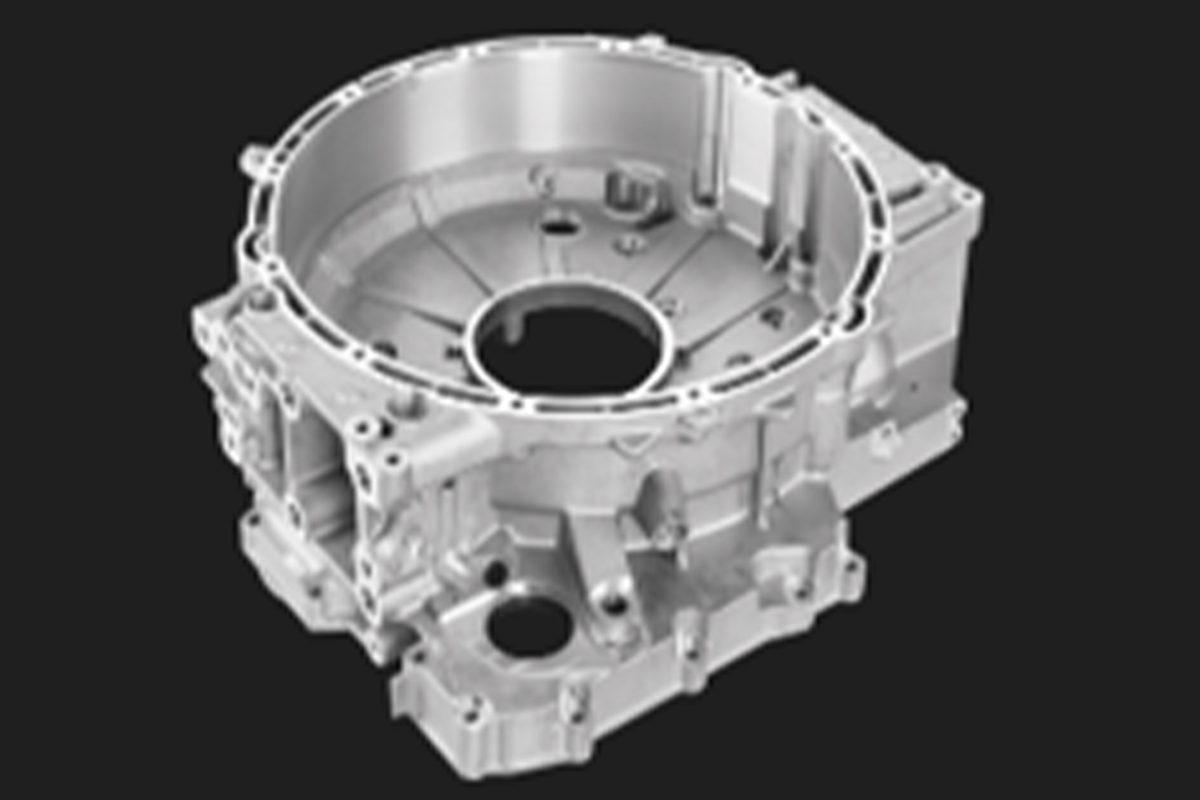

Zhihui Precision is capable of providing you with suitable and effective product surface treatment solutions. The process involves utilizing various technologies to alter and enhance the surface quality of products. Surface treatment techniques can improve both the aesthetics and functional properties of parts, including adhesion or wettability, solderability, corrosion resistance, anti-fouling properties, chemical resistance, wear resistance, hardness, modification of electrical conductivity, removal of burrs and other surface defects, as well as control of surface friction—all achieved through professional precision surface finishing.

With years of seamless collaboration with our surface treatment partners, we offer a range of high-quality surface treatment services for metals, composite materials, and plastics, bringing your envisioned prototypes or parts to life.

Surface finishing processes can be categorized based on their impact on the workpiece:

Removal or Reshaping Surface Treatments

Addition or Modification of Surface Treatments

Surface Finishing Overview

To ensure that the parts meet the desired process standards, perform stably and optimally in practical applications, and maintain their best condition, we conduct surface treatment operations after completing the appropriate processes or all machining procedures. This precision surface finishing process includes polishing, texturing, painting, anodizing, coating, electroplating, and related techniques—each integral to delivering top-tier precision surface finishing. These treatments are like dressing the parts in a "multifunctional outer layer," which not only significantly improves the appearance quality of the parts, making their texture more refined and aesthetically pleasing, but also provides comprehensive protective properties. In terms of stress relief and oxidation resistance, they effectively delay the aging process of the parts. In removing surface defects, they ensure the parts are put into use in perfect condition. Additionally, they significantly enhance properties such as chemical corrosion resistance and wear resistance, greatly extending the service life of the parts and enabling them to handle various complex working conditions with ease, operating stably and efficiently.

Surface Finishing Services Available

The surface treatment processes we can provide include:

Anodizing

Painting

Bead Blasting

Sanding and Polishing

Vapor Polishing

Color Matching

Texturing

Powder Coating

Electroplating

Pad and Silk Screen Printing

Factors to Consider When Choosing a Surface Treatment

Production Speed of the Surface Treatment Method: Consider the required delivery timeline. Evaluate the time involved in executing various procedures for alternative mixed-metal surface treatment options.

Hardness of the Metal is particularly important when applying secondary techniques. Harder metals require stronger abrasives during processing. Conversely, excessive force on softer materials may cause irreparable or difficult-to-repair damage to the parts.

Cost and Financial Projections: While several processes may seem ideal for your specific situation, some more challenging tasks may require specialized tools and equipment, potentially leading to budget overruns. Assess whether your decision will result in long-term cost savings.

Surface Finishing Services Capabilities

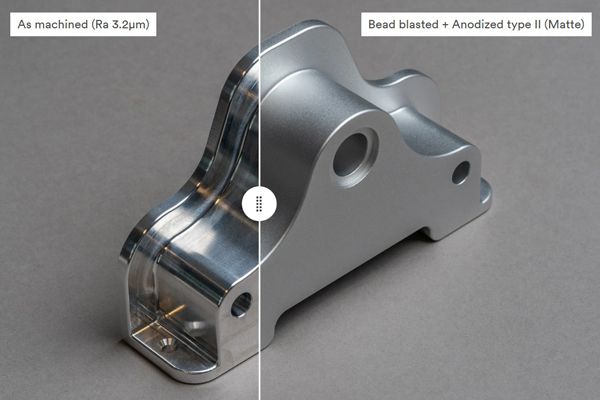

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of metal parts, enhancing their durability and resistance to corrosion. It works by immersing the metal in a chemical solution and passing an electric current through it, causing the metal to oxidize.

Standard: MIL-A-8625F, AMS2469,AMS2470 or AMS2471

Colors: Anodized natural, black, green, red

Test Specification: ASTM B117 336H

Application: Aerospace

Electroless nickel plating is a chemical process that deposits a nickel-phosphorus alloy onto a metal substrate without using an electric current, offering uniform coatings with good corrosion and wear resistance. Standard: GB/T 13913-92

Plating type: Electroless nickel

Test index: Hardness>800HV

Application: Automotive industry

Chrome plating is a technique of electroplating a thin layer of chromium onto a metal object. The chromium layer can be decorative, provide corrosion resistance, facilitate cleaning, and increase surface hardness. Sometimes it may be used for aesthetic purposes.

Standard: GS 90010

Type of plating: Decorative chrome

Plating testing standard: CASS 48H; NSS 360H.

Application: Automotive industry

Custom CNC machining parts are manually polished in multiple directions. The surface is smooth and slightly reflective.

Polishing Level: SPI A1 to B1

Roughness: Ra0.005 to Ra 0.05

Material: All materials

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

Color: Custom surface finishing

Texture: Glossy

Price: based on the requirements of the customer.

Material: All metal materials

Painting involves spraying a layer of paint onto the surface of the part. Color can be matched to a Pantone color number of the customer's choosing, while finishes range from matte to gloss to metallic。

Color: Custom

Texture: Gloss, semi-gloss, flat, metallic.

Price:

Material: Aluminum, Stainless Steel, Steel

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance, and to minimize light reflection. To achieve maximal corrosion resistance, the black oxide must be impregnated with oil or wax.

Color: black

Texture: Smooth, matte。

Price: based on the requirements of the customer.

Material: Steel, Stainless. Copper, Zinc.

Bead/Sand blasting, also known as abrasive blasting, is a process that uses compressed air to propel abrasive materials against a surface, smoothing, cleaning, or roughening it.

Color: custom.

Texture: custom.

Price: based on the requirements of the customer.

Material: all materials.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文