Quality Introduction Contents

Our Quality Policy

Zhihui Precision is committed to becoming a leader in the field of 5-axis CNC machining. We understand that quality is the lifeline of our enterprise and the cornerstone of customer trust. Leveraging advanced equipment and manufacturing processes, stringent quality assurance measures, and adherence to industry standards, we ensure that your parts and prototypes are of high quality, precision, and durability.

To this end, we have established the following quality policy, which is integrated into every aspect of our production and operations:

Customer First: We always prioritize customer needs, aiming for customer satisfaction as our ultimate goal, and delivering high-quality products and services.

Striving for Excellence: We pursue perfection, continuously improving production processes and management standards, striving to perfect every detail.

Full Participation: We believe that quality is the shared responsibility of all employees. We encourage every team member to actively participate in quality management and contribute to enhancing product quality.

Continuous Improvement: We constantly learn advanced technologies and management practices, actively introduce new equipment and processes, and continuously improve our quality management system to provide even better services to our customers.

Integrity in Operations: We adhere to ethical business practices, strictly comply with industry norms and standards, and ensure the reliability and authenticity of product quality.

Zhihui Precision will steadfastly uphold the quality policy of "Striving for Excellence, Pursuing Perfection," rewarding customer trust with high-quality products and services. Together with our customers, we look forward to creating a brighter future!

Quality Control Procedure

Check the customer's part specification sheet.

Design optimization control.

Material Incoming inspection(right material, material composition, hardness, etc.).

Process Inspection.

Full inspection for all parts before shipment. (CMM, 2D Projector, Scanner, etc.).

CT scanner ( if needed, as it's an additional cost ).

Dynamic Balance inspection.

Pre-assembly & Parts packing inspection

-

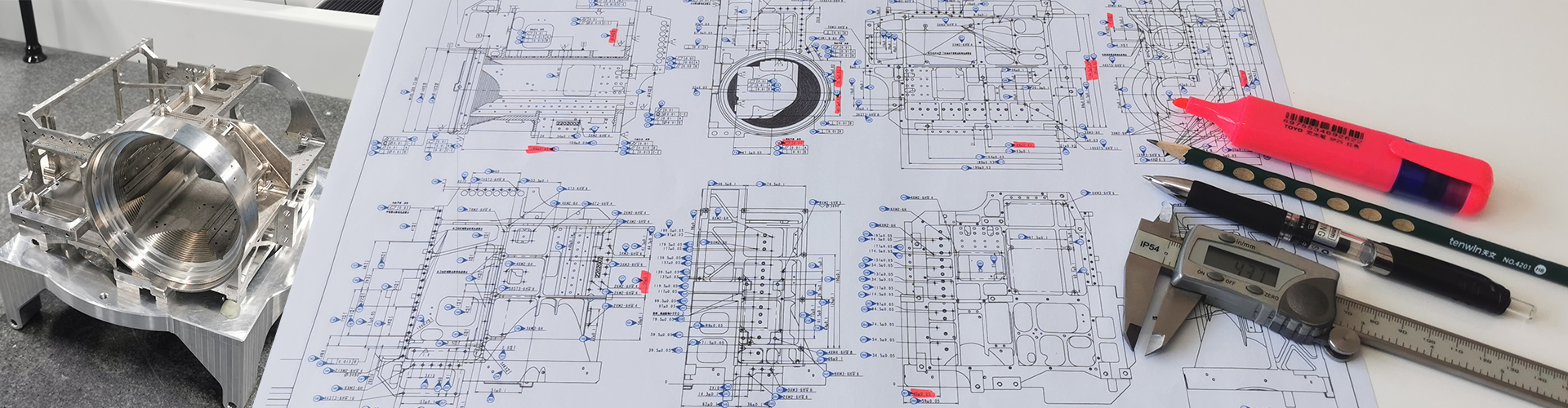

Check Customer Part Drawing & Specification Sheet

Quality control begins with the initial receipt of customer data, including detailed 2D product drawings and product specifications. Only by fully understanding and thoroughly digesting the customer's information can we effectively ensure quality.

-

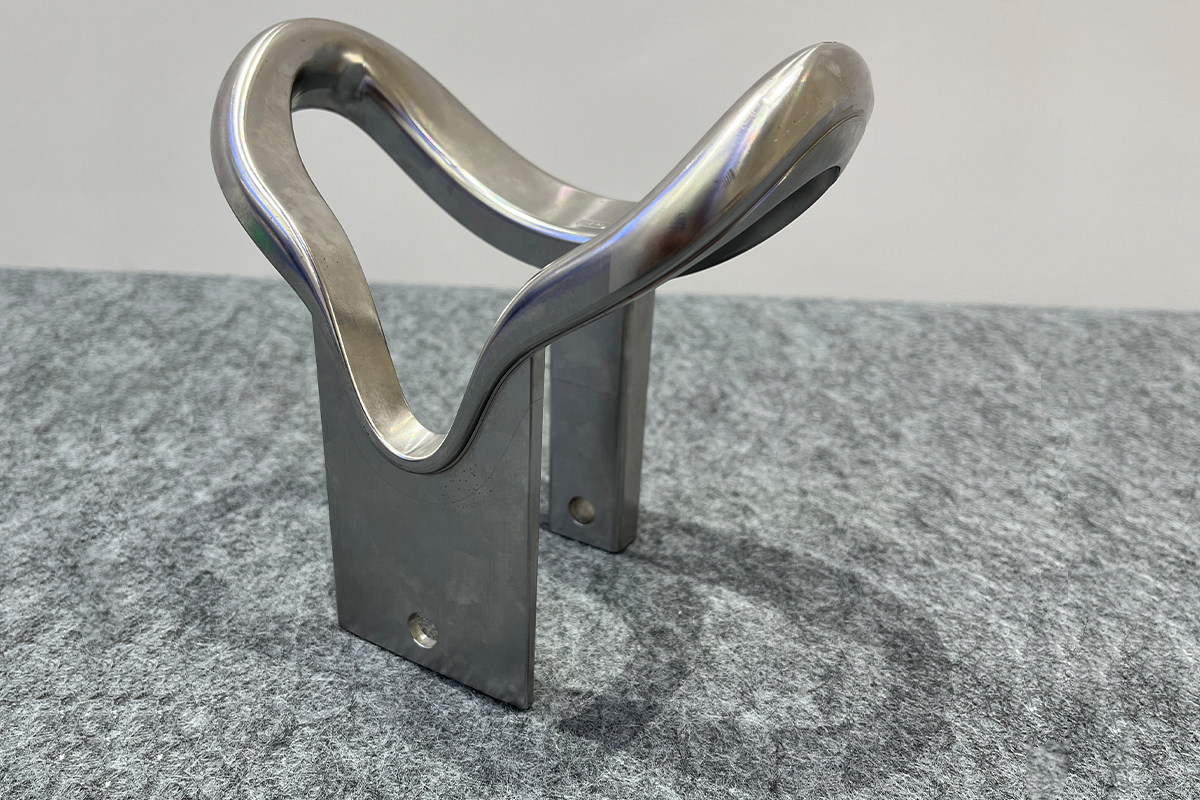

Design Optimization Control

After fully understanding and assimilating the customer's information, we provide effective analysis and suggestions for the product design to ensure that the final product achieves perfect quality, high precision, and durability after processing.

-

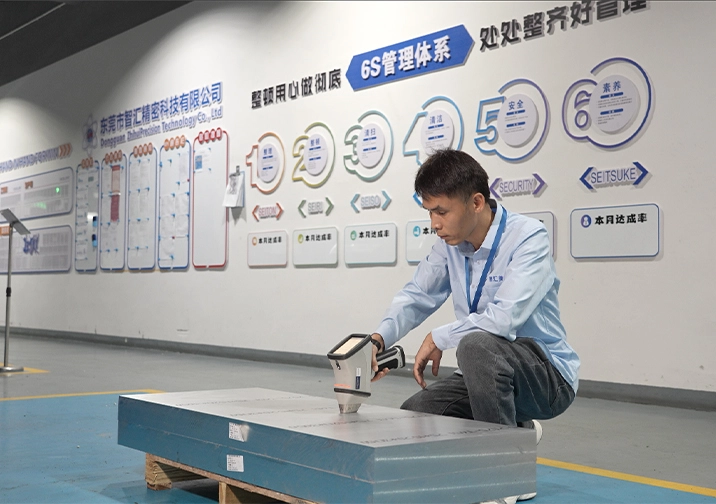

Material Incoming Inspection

Incoming material inspection is an extremely critical step in ensuring product quality. Only by confirming that the materials meet the customer's product design requirements can we manufacture high-quality products. Incoming material inspection includes verifying the correct material type, material composition, hardness, and other relevant indicators.

-

Process Inspection

Quality control during the production process is a crucial aspect of ensuring product quality. For process quality control, all of our 5-axis machines are equipped with Renishaw online measurement systems. Additionally, we have a dedicated team ready to support any measurement needs during the process to guarantee the production of high-quality products.

-

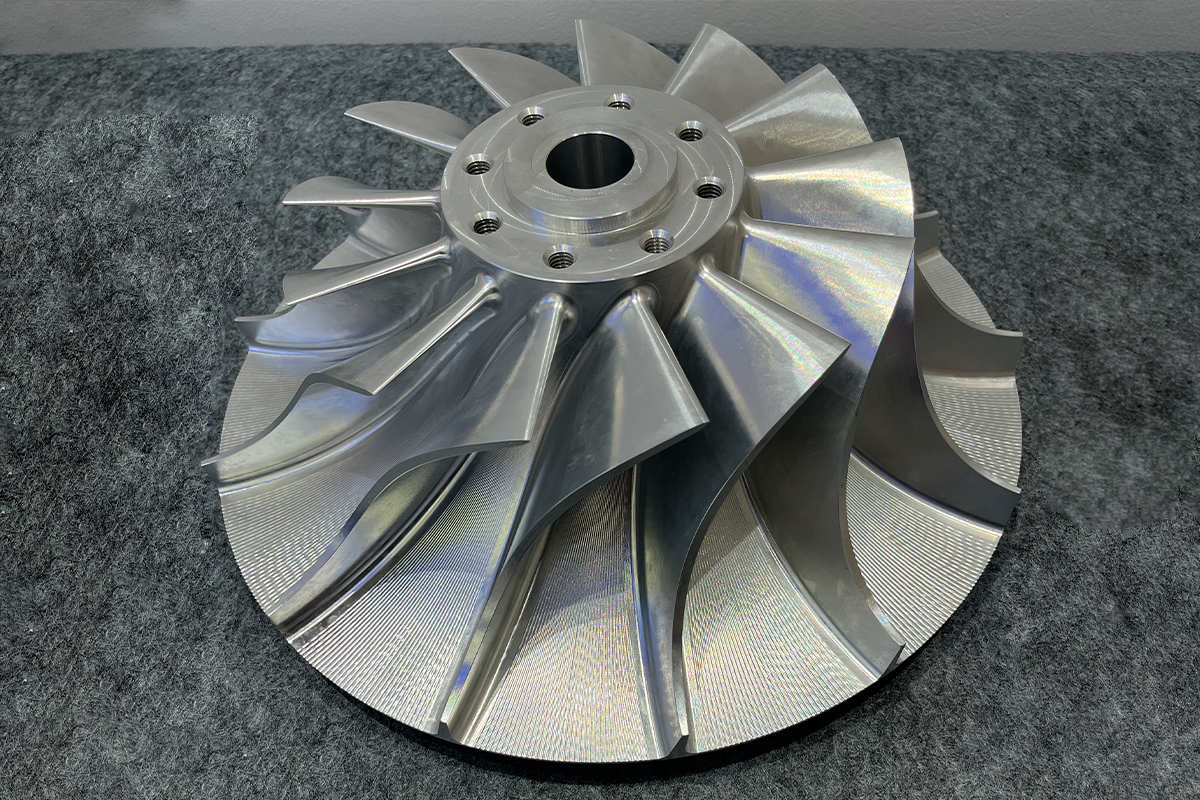

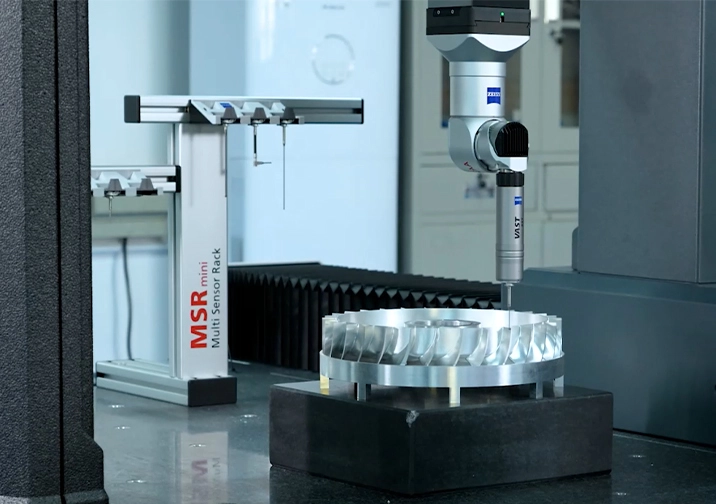

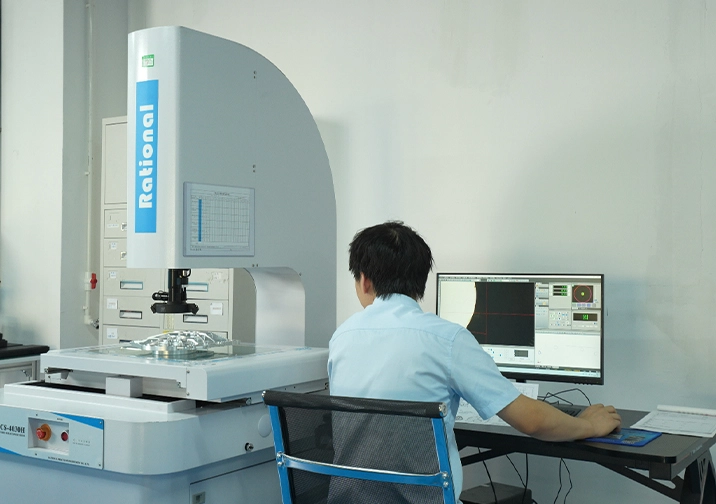

Full Inspection For All Parts Prior

To ensure the high quality of our products, we conduct detailed full-size inspections on all products before delivery to customers. For mass production, we perform sample trial production before official manufacturing and provide comprehensive First Article Inspection (FAI) reports. All quality control activities are aimed at achieving high product quality and strictly adhering to relevant standards.

-

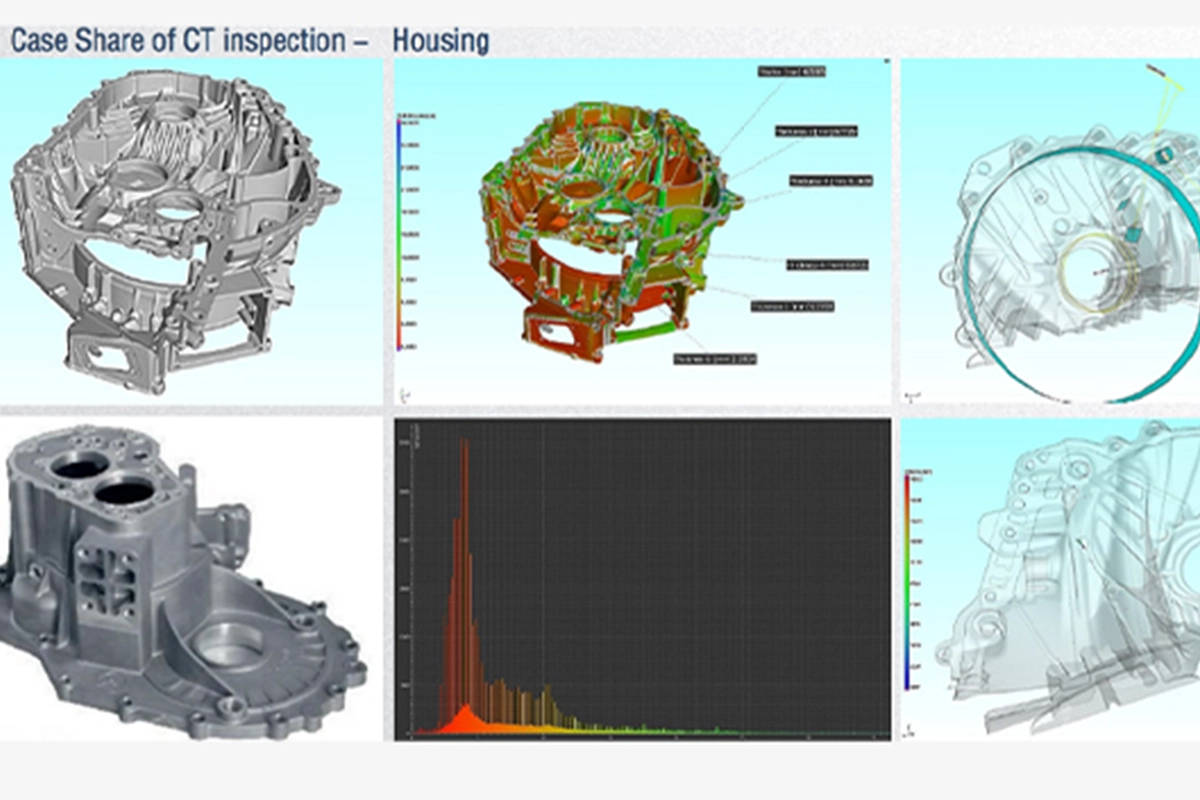

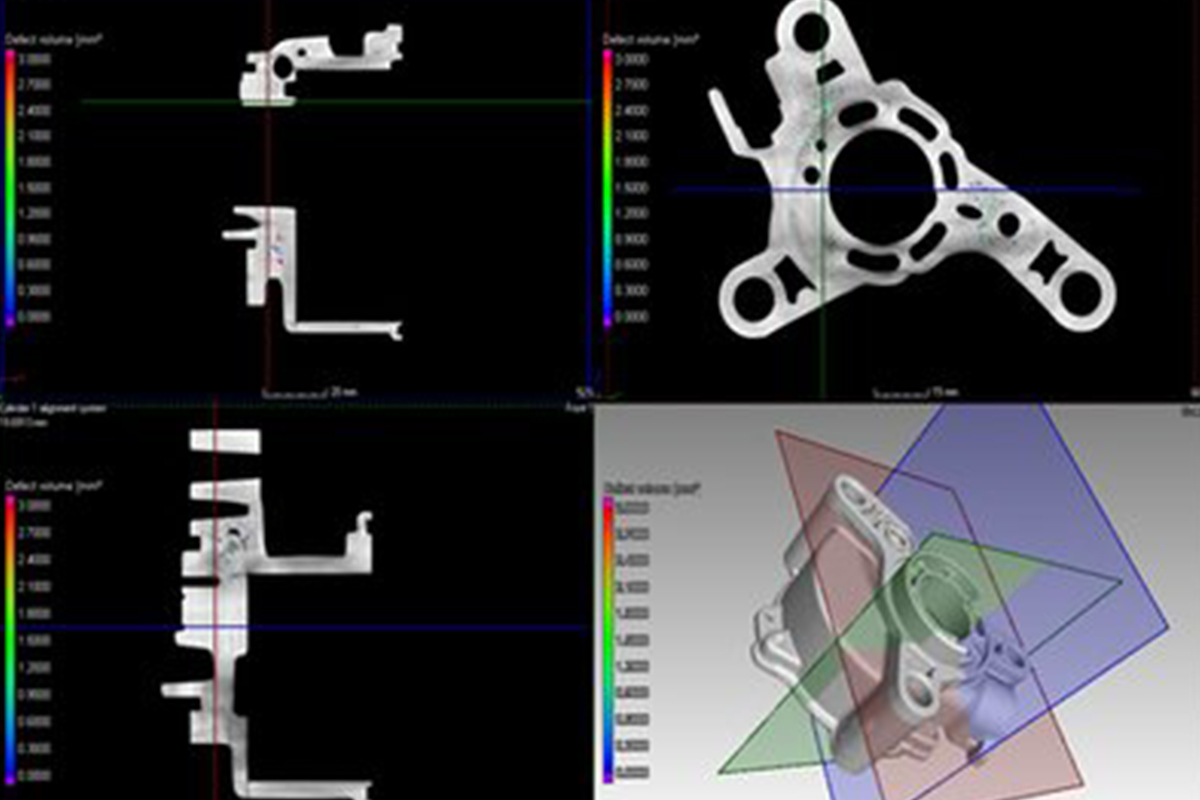

CT Scanner

Zhihui Precision can provide CT measurements.

And the advantages of CT measurements:

•Certainty

Measure, analyze, and inspect defects and structures inside workpieces with just one exposure.

•Non-destructive

Thanks to CT and X-ray, measurement is possible without destroying the components.

•Reproduction

Digitization via computed tomography enables the reproduction of components even without a CAD model.

-

Dynamic Balance Inspection

Our company is equipped with industry-leading dynamic balancing testing equipment, featuring high-precision sensors and intelligent analysis systems. This advanced technology enables us to accurately identify even the slightest imbalances in products during high-speed operation, ensuring smooth and reliable performance. This state-of-the-art equipment provides robust technical support for our customers' product quality inspections, significantly enhancing product performance and lifespan, and fully meeting our customers' stringent requirements for high-quality products.

-

Pre-assembly & Parts Packing Inspection

We offer comprehensive product assembly inspection services, including assembly performance and functional testing, to help customers identify potential issues before product assembly, preventing any impact on the overall project timeline due to assembly problems. Additionally, we provide tailored packaging solutions to ensure products remain intact during transportation, eliminating quality issues caused by improper packaging. Furthermore, we deliver First Article Inspection (FAI) reports, material certifications, and other technical documents to fully meet our customers' delivery requirements.

Quality Certifications

Inspection & Measurement Equipment

Maximum Size Measured: 1700*1200*1000mm & Maximum Weight Measured: 2200kg

Material inspection (right material, material composition, hardness etc.)

Response Quickly and Effectively to Quality Issues

We always prioritize our customers' interests and maintain zero tolerance for quality issues.

With speed as our shield and efficiency as our spear, we have established a comprehensive rapid response mechanism for quality issues, supported by an experienced quality team.

Upon receiving feedback regarding quality concerns, we commit to immediately activating our emergency response mechanism to identify, analyze, and resolve issues at the earliest stage.

By addressing problems with precision and speed, we eliminate potential risks at their root, minimize customer losses, and provide the most reliable quality assurance.

Rework Conditions:

After advising us of the concern, we review the design and samples to check for inconsistencies. Then we will fix the complaints and send replacements immediately.

Unacceptable processing defects.

Fail to meet tolerance requirement.

Incorrect material/finish.

Refund Conditions:

Refunds are quickly processed upon confirmation of product issues, and return is processed.

The part is unable to machining.

The customer does not agree to rework.

Other reasons.

Quality Assurance

Why Quality Assurance Matters

While CNC machining delivers exceptional accuracy, maintaining consistent quality requires rigorous validation processes. Here's why these measures are indispensable across industries:

Core Benefits of Systematic Quality Control

Performance Assurance

Even microscopic deviations in component specifications can lead to complete system failures. In sectors like aviation or medical technology, where tolerances are measured in microns, such errors may compromise safety and functionality.Longevity Optimization

Comprehensive material testing ensures components withstand operational stresses, preventing premature failures in critical applications from industrial machinery to prosthetic implants.Economic Advantages

Early defect detection significantly reduces waste and associated costs. Industry studies show that identifying issues during production can lower expenses by 40-60% compared to post-manufacturing corrections.Market Reputation

Consistent quality standards build client confidence and brand equity, directly influencing long-term business success through repeat engagements and referrals.

Advanced Quality Verification Methods

Modern quality assurance combines cutting-edge technology with expert analysis:

Precision Measurement Systems

Non-contact 3D scanners and high-precision CMMs validate dimensional accuracy to sub-micron levels

Traditional instruments like digital micrometers remain essential for rapid in-line measurements

Surface Characterization

Advanced profilometry evaluates critical surface texture parameters that affect performance characteristics like friction, wear resistance, and fluid dynamics

Material Certification Processes

Destructive testing methods verify theoretical material properties against actual performance

Sophisticated non-destructive evaluation techniques examine internal structures without compromising part integrity

Functional Validation

Simulated operational testing confirms components perform as intended under real-world conditions

Data-Driven Process Control

Automated statistical analysis identifies production trends and prevents quality deviations before they occur

The Human Element in Quality Management

While automated systems excel at repeatable measurements, human expertise provides:

Contextual Understanding: Interpreting subtle anomalies beyond programmed parameters

Diagnostic Insight: Identifying root causes of complex quality issues

Adaptive Solutions: Developing customized verification approaches for unique projects

Operational Benefits of Robust Quality Systems

Preventive Process Optimization

Strategic quality checkpoints minimize production disruptions and downstream correctionsResource Efficiency

Accurate inspections reduce material waste and improve sustainability metricsSchedule Reliability

Fewer post-production issues ensure predictable delivery timelines

Industries with Exceptional Quality Demands

Several sectors impose particularly stringent requirements:

Aerospace Engineering: Components must endure extreme environmental stresses while maintaining structural integrity

Medical Technology: Implants and surgical instruments demand absolute precision and biocompatibility

Automotive Manufacturing: Safety-critical systems require flawless execution of complex assemblies

Electronics Production: Miniaturized components need exacting dimensional and conductivity standards

In these fields, quality assurance transitions from optional best practice to fundamental operational requirement.

Selecting a Quality-Focused Manufacturing Partner

Key indicators of excellence include:

Investment in latest-generation inspection technology

Recognized quality certifications with regular third-party audits

Transparent reporting practices with detailed measurement documentation

Demonstrated commitment to continuous process improvement

Strategic Importance of Quality Assurance

Beyond basic compliance, comprehensive quality systems serve as:

Risk Mitigation Framework: Preventing costly failures and recalls

Value Creation Mechanism: Differentiating products in competitive markets

Innovation Enabler: Providing the reliability foundation for advanced designs

Organizations that embed quality principles throughout their operations, rather than treating it as a final inspection, achieve superior market positioning and long-term profitability.

This framework can be further customized based on specific industry requirements or particular quality challenges your organization faces. Would you like to explore any aspect in greater technical depth?

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文