-

Introduction to the basic Situation of Prototyping

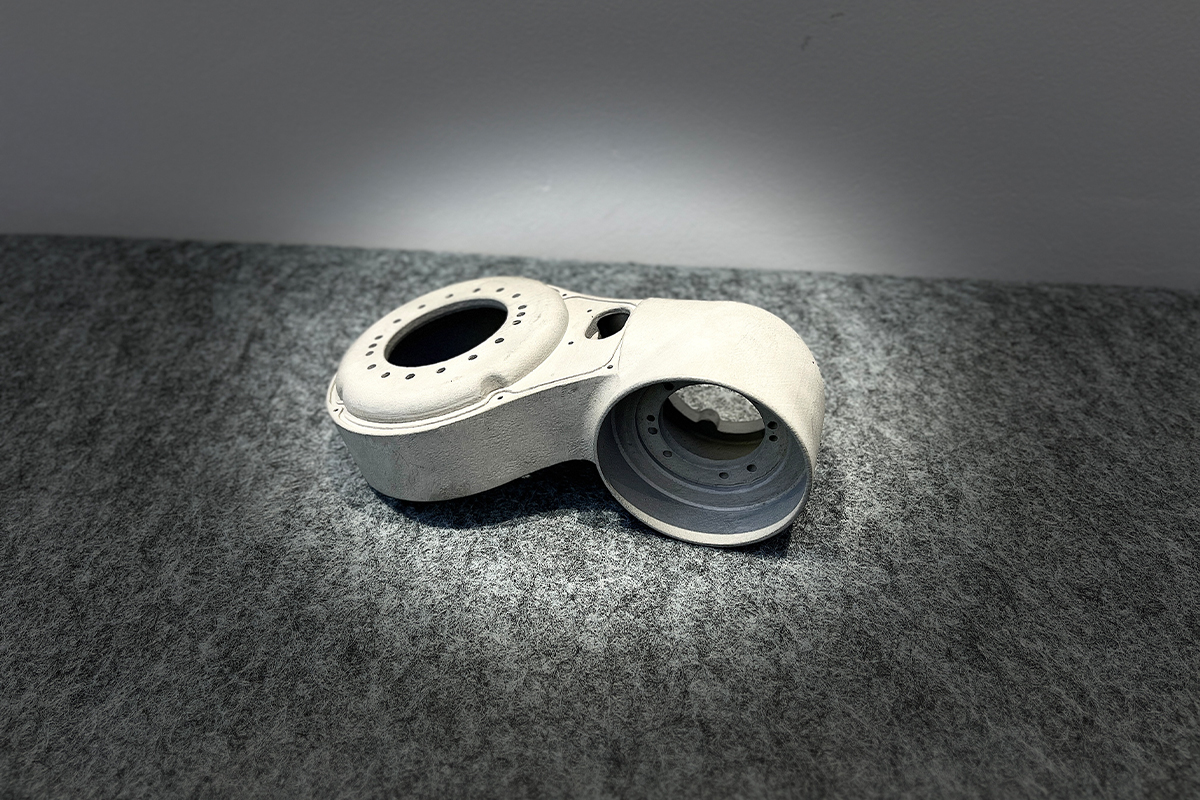

Rapid Prototyping (RP) is a technology that transforms early-stage design concepts into physical prototypes using digital models, providing a fast and cost-effective method to turn ideas into reality. This approach, leveraging techniques such as 3D printing and CNC machining, is highly efficient, often delivering prototypes within 1-3 working days. It is widely used in product design, development, and testing phases.

Choosing prototyping is crucial for accelerating the design process while reducing financial and operational risks associated with new product development. It allows for thorough testing and refinement of designs, ensuring each iteration improves upon the previous one. This process is essential for making informed decisions early in the development cycle, minimizing the risk of costly modifications later.

Rapid prototyping quickly converts early-stage design concepts into physical models, offering a fast and economical way to bring ideas to life. Below are the key characteristics of rapid prototyping:

High Speed: Rapid prototyping can transform design concepts into physical models in a short time, significantly shortening the product development cycle and enabling teams to validate designs quickly.

High Precision: Utilizing advanced digital technologies (e.g., 3D printing, CNC machining), it can accurately replicate complex geometries and details, meeting high-precision design requirements.

Design Flexibility: It supports complex structures and customized designs, allowing for rapid iteration and modification to adapt to design changes.

Material Diversity: A variety of materials, such as plastics, resins, metals, and ceramics, can be used to meet different functional testing and performance validation needs.

Cost-Effectiveness: Compared to traditional manufacturing methods, rapid prototyping reduces mold development and production preparation time, lowering the cost of producing small-batch prototypes.

Functional Validation: Prototypes can be used not only for visual evaluation but also for functional testing, such as assembly tests, stress analysis, and fluid dynamics testing.

Risk Reduction: By identifying design flaws early through rapid prototyping, it minimizes the need for costly modifications and production risks before mass production.

Support for Multiple Processes: These include but are not limited to 3D printing (e.g., FDM, SLA, SLS), CNC machining, and vacuum casting, allowing the selection of the most suitable process based on requirements.

Eco-Friendliness and Sustainability: Rapid prototyping often employs additive manufacturing techniques, which have high material utilization and low waste, aligning with green manufacturing principles.

Wide Range of Applications: It is suitable for industries such as automotive, aerospace, medical, electronics, and consumer goods, supporting the entire development process from concept design to functional validation.

In summary, rapid prototyping has become an indispensable tool in modern product development due to its efficiency, flexibility, precision, and cost-effectiveness, helping businesses accelerate innovation and reduce development risks.

Rapid CNC Prototyping Service

Rapid CNC Prototyping Service

Rapid CNC Prototyping bridges the gap between design and production, offering precision, material flexibility, and scalability. While 3D printing excels in speed for complex geometries, CNC remains unmatched for high-strength, functional prototypes in industries like automotive and aerospace. By leveraging advanced software and hybrid approaches, it continues to evolve as a cornerstone of agile manufacturing.

When to Choose Rapid CNC Prototyping:

Functional Testing: Requires material properties identical to final production.

High-Precision Parts: Critical for fit, form, and function validation.

Metal Components: Superior to 3D printing in strength and durability.

Introduction of Rapid 3D Printing Prototyping Process

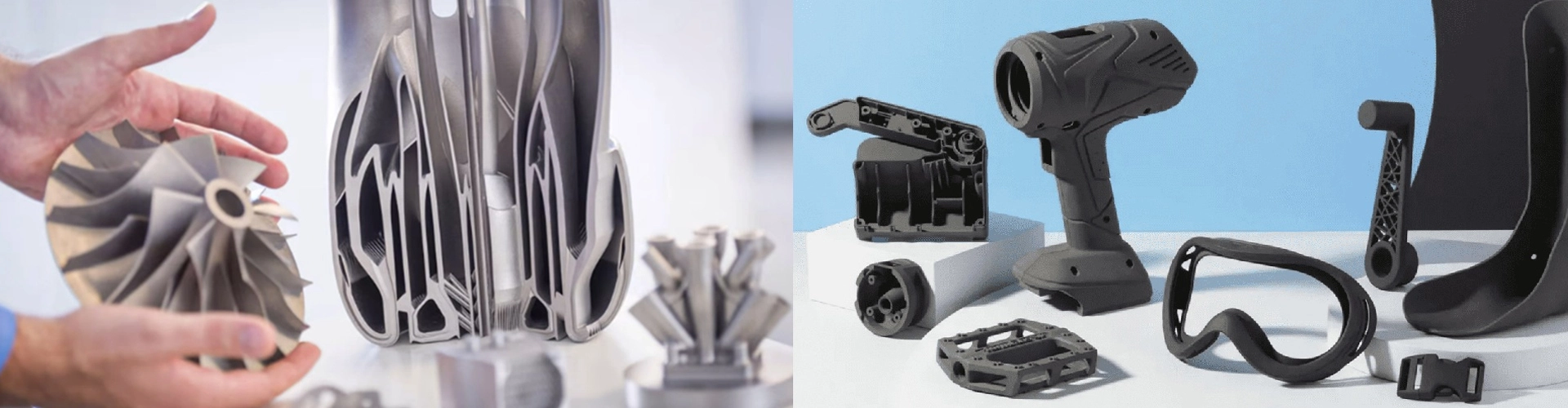

Rapid 3D Printing Prototyping: A Comprehensive Guide 3D printing (additive manufacturing) has revolutionized prototyping by enabling rapid iteration of complex designs at a fraction of the time and cost of traditional methods. Below is a detailed breakdown of its process, strengths, limitations, and applications:

Process Overview

Design Preparation:

Create a 3D CAD model and export it as an STL/OBJ file.

Use slicing software (e.g., Cura, PrusaSlicer) to generate layer-by-layer instructions.

Material Selection:

Polymers: PLA, ABS, PETG (FDM), Resins (SLA/DLP), Nylon (SLS).

Metals: Stainless steel, titanium, aluminum (DMLS/SLM).

Composites: Carbon fiber-infused, ceramic-filled filaments.

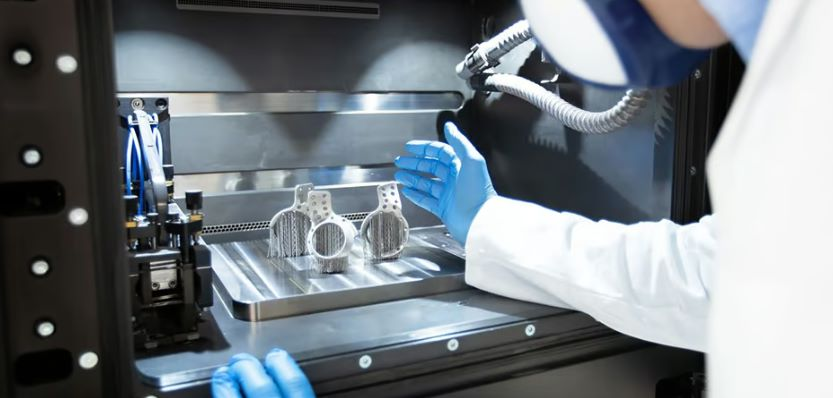

Printing:

Layer-by-layer deposition (FDM), photopolymer curing (SLA), or laser sintering (SLS/DMLS).

Print times range from minutes (small parts) to days (large, intricate builds).

Post-Processing:

Remove supports, sand, polish, or paint.

Heat treatment (for metal parts) or UV curing (resins).

Conclusion: Rapid 3D printing prototyping is a game-changer for agile product development, offering unparalleled design freedom and speed. While it has limitations in material performance and scalability, advancements in multi-material systems, metal printing, and AI-driven design are expanding its capabilities. By strategically pairing 3D printing with CNC or molding, teams can accelerate innovation while balancing cost, quality, and time.

| Industry | Use Cases | Common Technologies/Materials |

| Automotive | Ducts, brackets, and custom jigs | FDM (ABS, Nylon), SLS (PA12) |

| Aerospace | Lightweight brackets, turbine blades | DMLS (Titanium, Inconel) |

| Medical | Surgical guides, prosthetics, and dental models | SLA (Biocompatible resin), SLS (Nylon) |

| Consumer Goods | Ergonomics testing, packaging prototypes | FDM (PLA), MultiJet (Wax-like resins) |

| Electronics | Enclosures, heat sinks, and connectors | SLA (High-detail resin), FDM (PC Blend) |

| Architecture | Scale models, structural mockups | FDM (PLA), Binder Jetting (Sandstone) |

Advantages & Disadvantages of Prototyping

Prototyping is a critical phase in product development, enabling teams to test ideas, gather feedback, and refine designs before full-scale production. Below is a structured analysis of its key benefits and potential drawbacks:

Advantages of Prototyping

Early Feedback & Validation

Improved Communication

Cost Efficiency

Flexibility & Creativity

User-Centered Design

Technical Verification

Disadvantages of Prototyping

Time & Cost Overruns

Misleading Expectations

Technical Limitations

Focus on Aesthetics Over Function

Reduced Innovation

Waste Generation

Prototyping is invaluable for minimizing risk, enhancing user experience, and accelerating innovation. While challenges like cost and scope creep exist, strategic planning and clear communication can maximize its benefits. Whether physical or digital, prototyping remains a cornerstone of agile, user-centered design across industries.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文