As a professional 5-axis CNC machining service provider, we deliver high-precision, high-complexity core component solutions for the marine industry.

Types of Shipbuilding We Can Manufacturing

5-Axis CNC Machining for the the Shipbuilding Industry

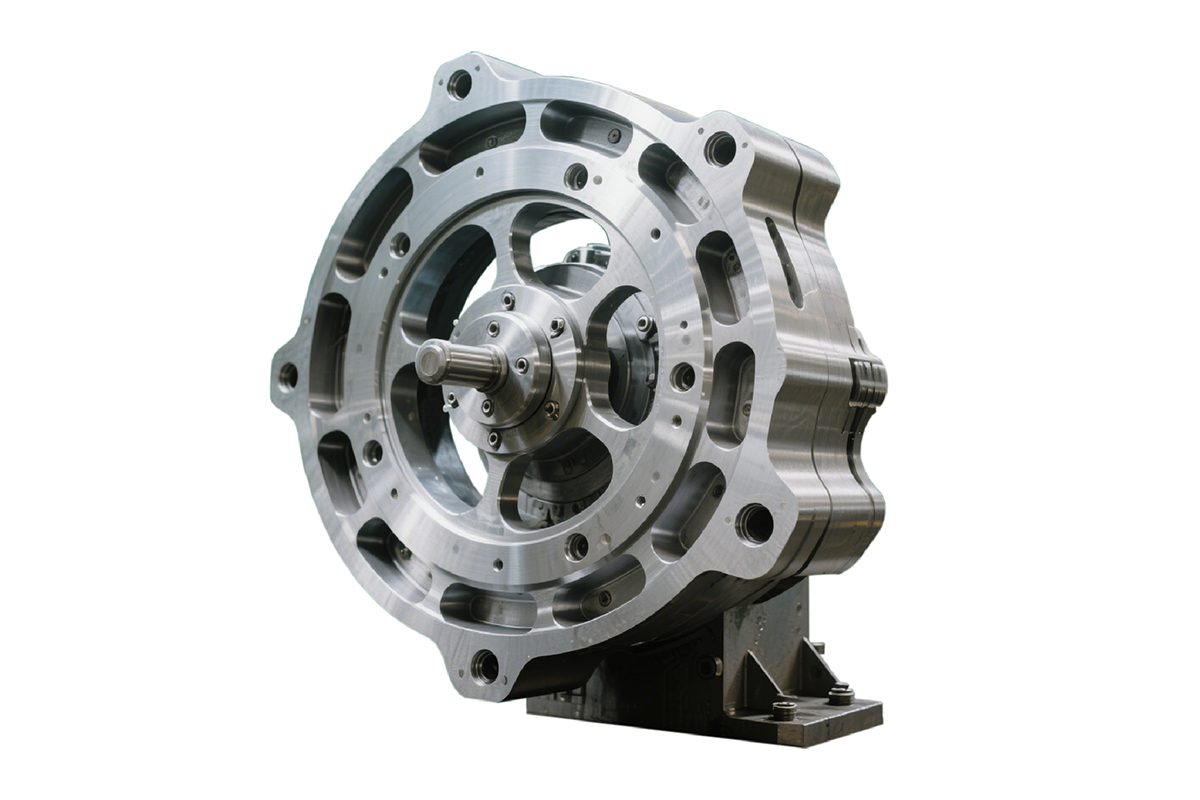

As a professional 5-axis CNC machining service provider, we deliver high-precision, high-complexity core component solutions for the marine industry. Utilizing advanced 5-axis simultaneous machining technology, we efficiently process critical marine components, including propulsion systems, power units, and hull structural parts, ensuring reliability and durability under high-salinity, high-pressure, and extreme operating conditions. With extensive experience in machining stainless steel, titanium alloys, and specialty materials, we help clients shorten marine equipment development cycles while improving dimensional accuracy and assembly compatibility. Our solutions strictly comply with DNV-GL, ABS, and other international classification society certifications, providing robust precision machining support for shipbuilders to achieve lightweight design and energy efficiency goals.

Advantages of 5-Axis Machining for Shipbuilding Industry

5-axis machining technology demonstrates significant advantages in shipbuilding, with core value manifested in:

Its multi-axis synchronized machining capability enables single-setup completion of complex surfaces, irregular structures, and high-precision holes, substantially reducing fixture changes for critical marine components (propellers, crankshafts, marine engine blocks, etc.), minimizing repositioning errors, and improving machining accuracy and surface quality.

The technology efficiently processes spatial-angle features unachievable by conventional methods, such as precision milling of hull section welding grooves and forming of streamlined components (fairings), thereby optimizing hydrodynamic performance while reducing energy consumption and noise.

With superior adaptability to difficult-to-machine materials (titanium alloys, high-strength steels) and intelligent toolpath planning, it significantly improves material utilization and shortens production cycles for large structural components - particularly suitable for shipbuilding's customized, small-batch requirements while supporting lightweight and modular design approaches.

Why Choose Zhihui Precision

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文