As a technology pioneer specializing in 5-axis CNC machining, we provide high-complexity manufacturing solutions for semiconductor industry components with sub-micron precision and multi-axis machining capabilities, serving the needs of semiconductor parts suppliers worldwide.

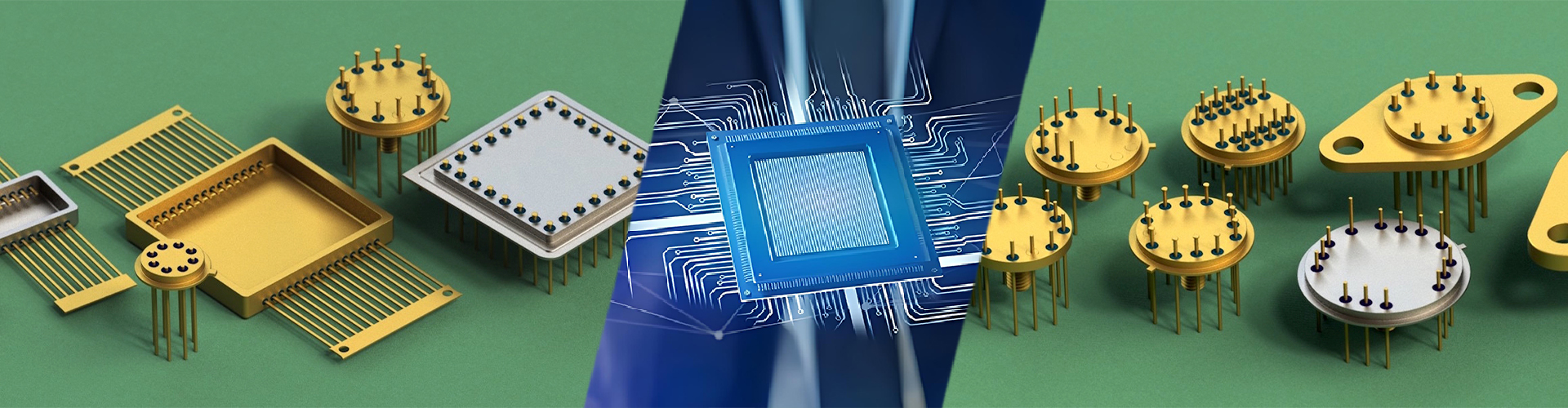

Types of Semi-conductor We Can Manufacturing

5-Axis CNC Machining for the the Semi-conductor Industry

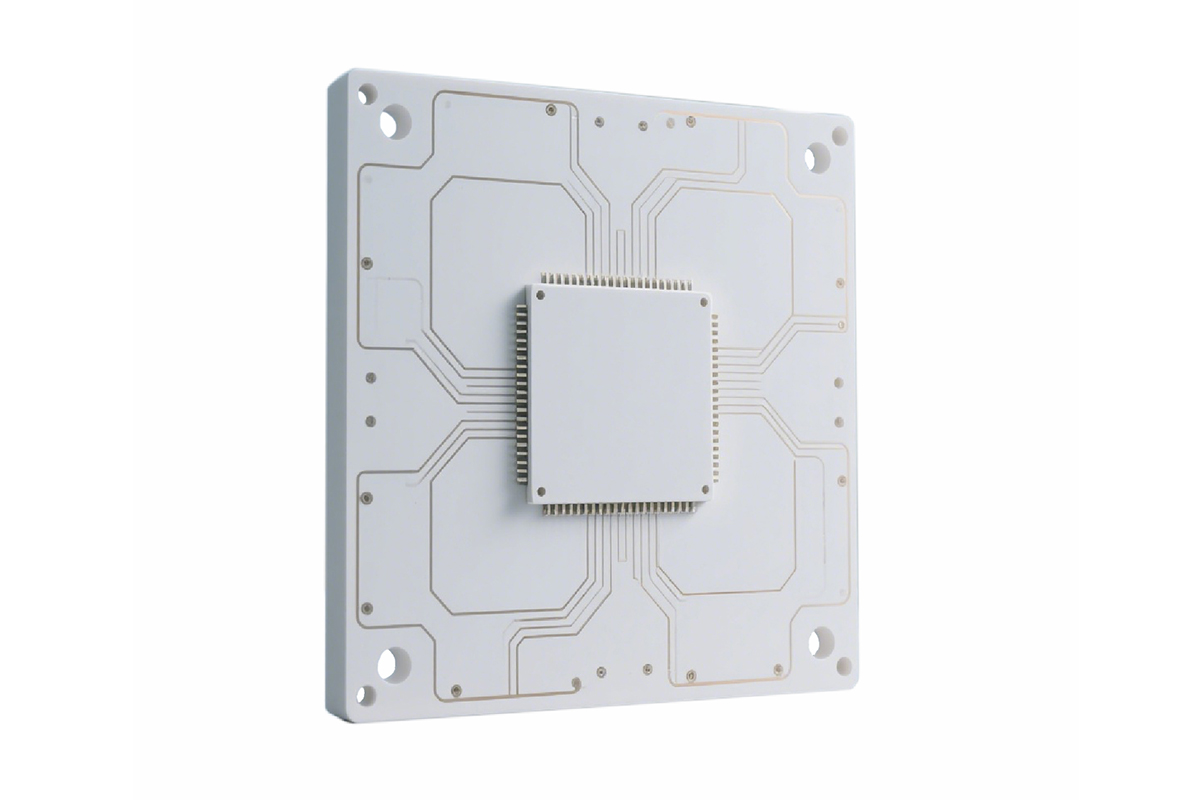

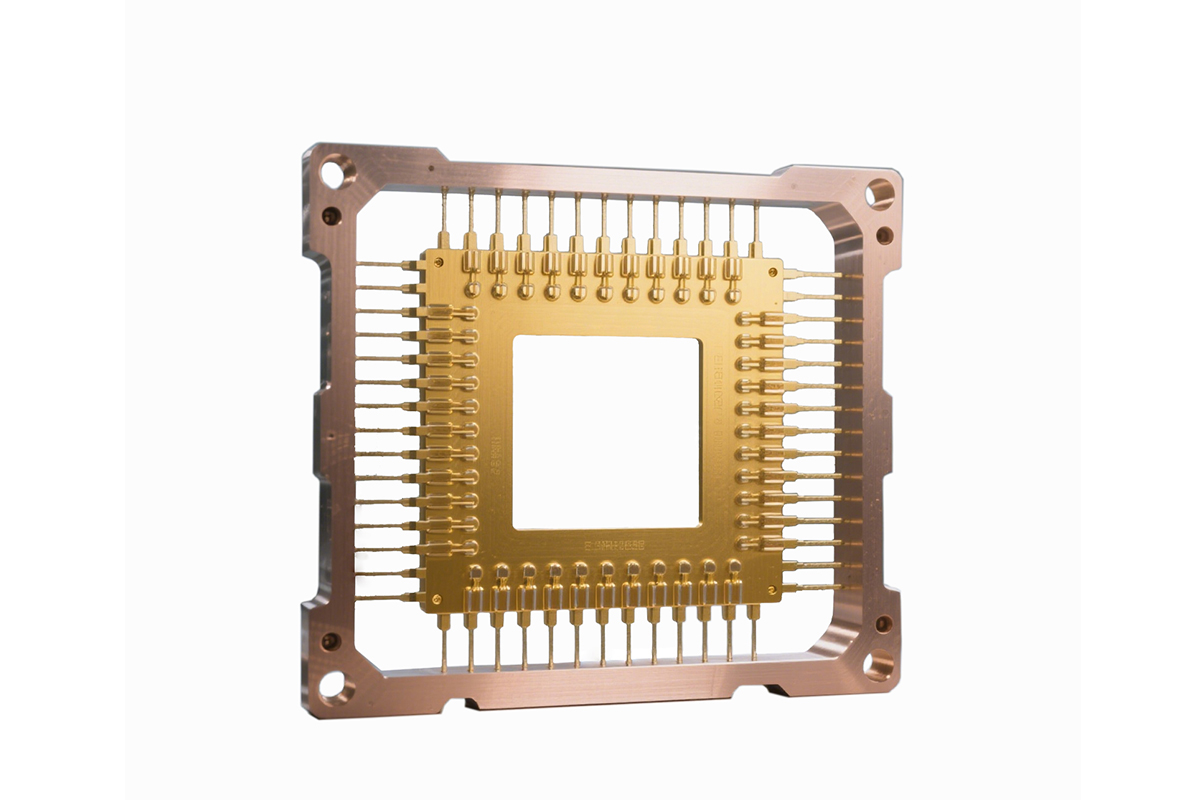

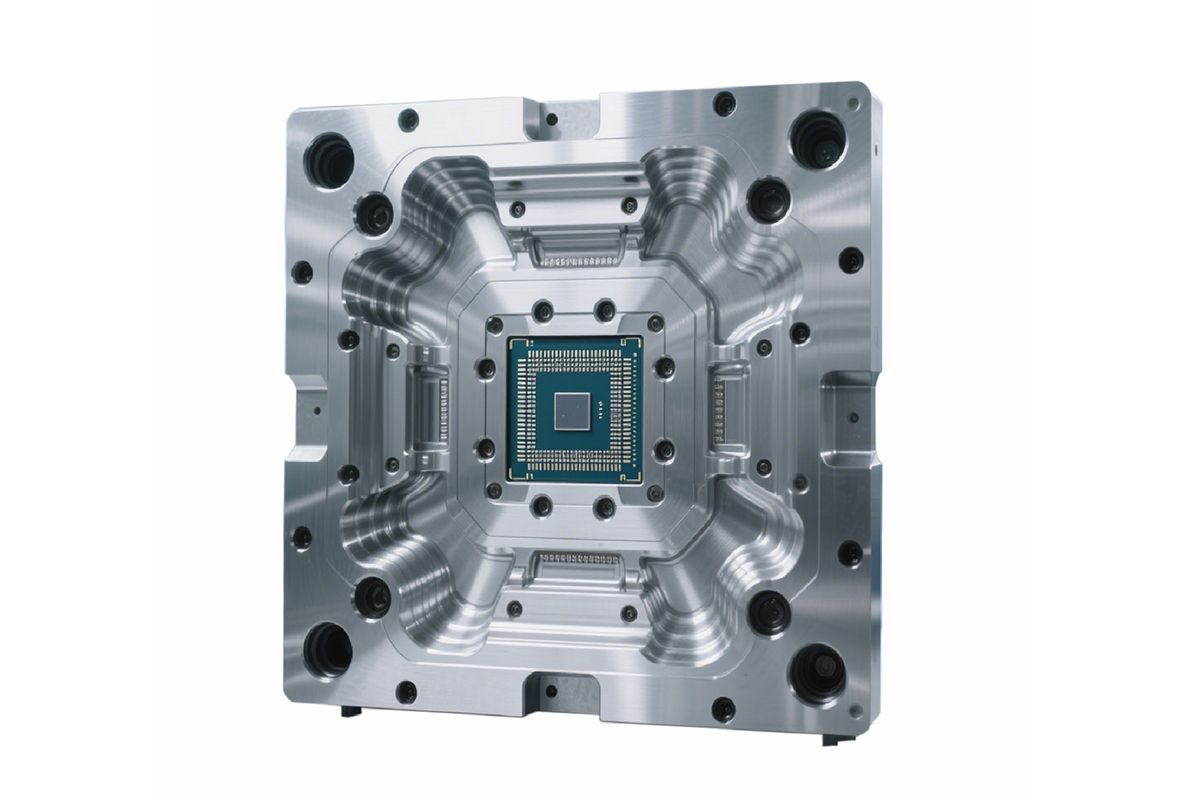

As a technology pioneer specializing in 5-axis CNC machining services, we provide high-complexity manufacturing solutions for semiconductor industry components with sub-micron precision and multi-axis machining capabilities. For critical semiconductor equipment parts, including processing tools and packaging components, we optimize machining processes for metals, ceramics, and composites to ensure nanometer-level surface finish and structural stability. Through our comprehensive quality control system and rapid response mechanism, we not only accelerate R&D cycles for high-end components but also support semiconductor industry innovation toward smaller dimensions and higher integration with customized machining solutions, serving as a reliable partner for semiconductor manufacturing technology advancement.

Advantages of 5-Axis Machining for Semiconductor Industry

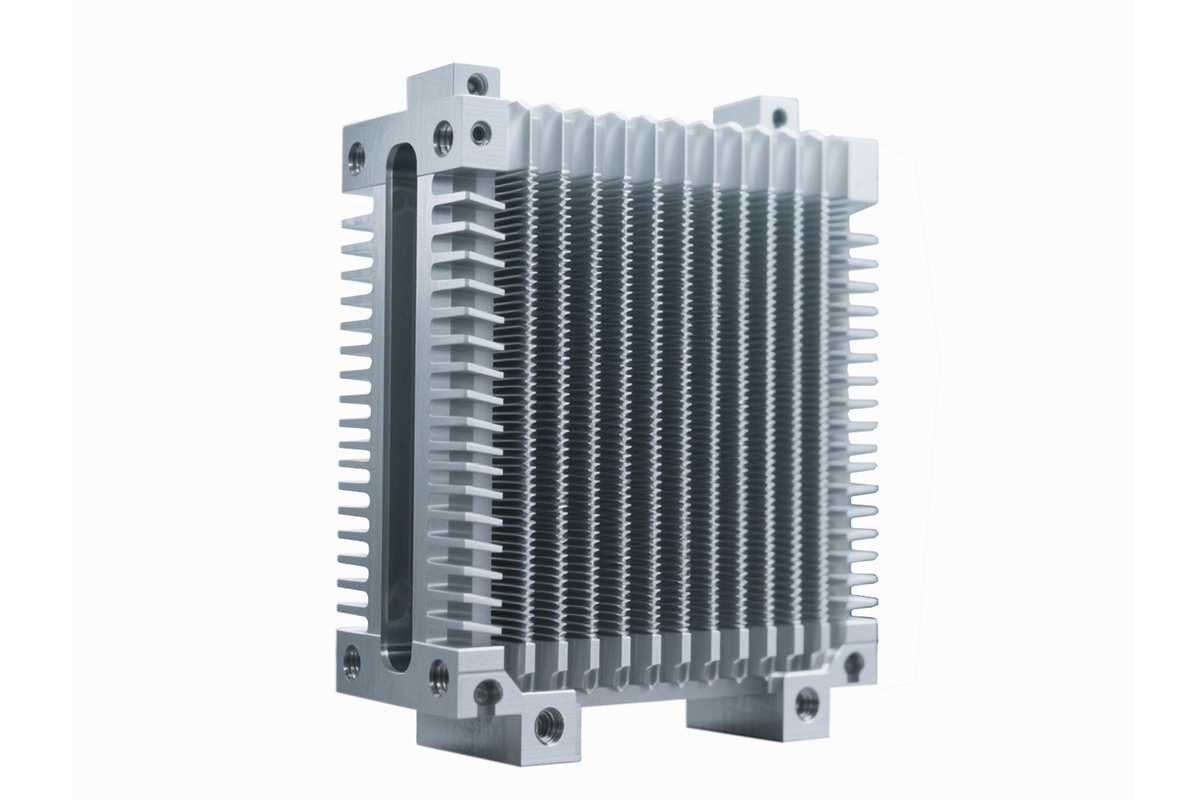

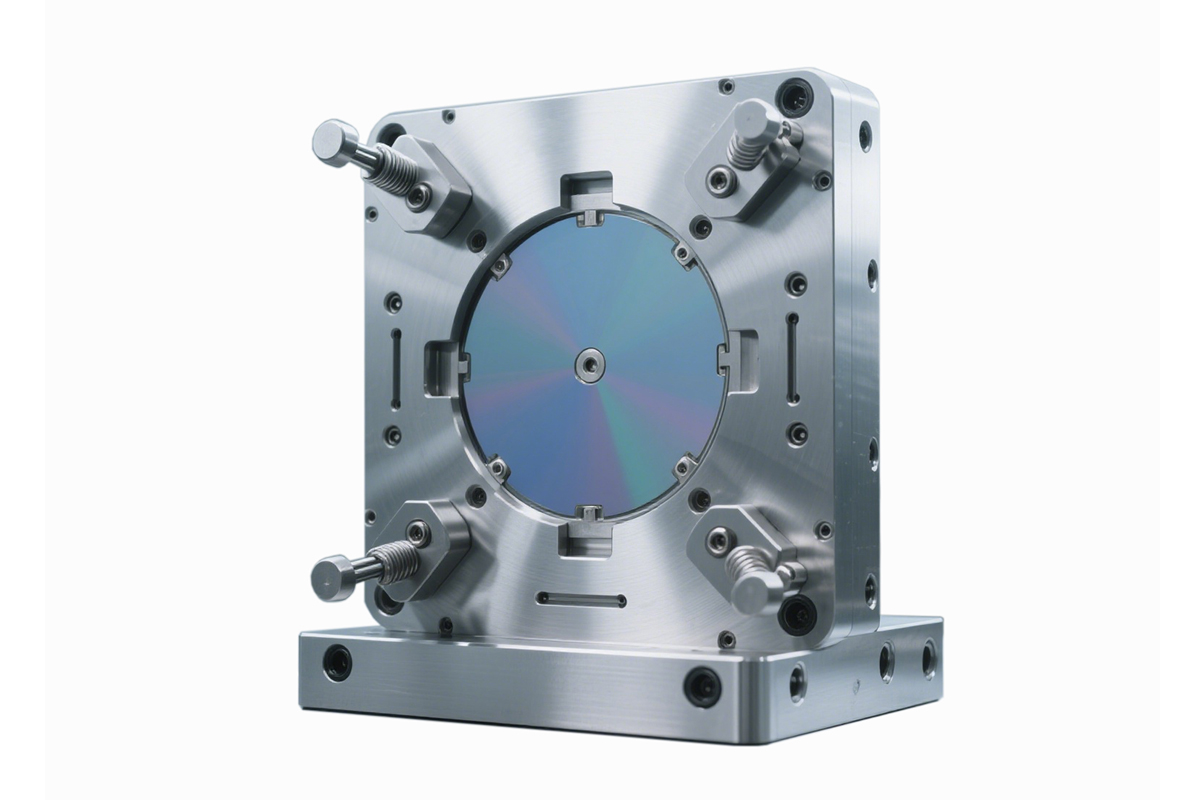

5-axis CNC machining offers core advantages in semiconductor manufacturing by enabling efficient, high-precision processing of complex geometries (e.g., wafer clamps, vacuum chambers, optical components). Its multi-axis synchronization and single-setup capability allow complete multi-surface machining, significantly reducing repositioning errors (achieving micron-level accuracy). The technology also supports precision machining of semiconductor-grade hard and corrosion-resistant materials (e.g., ceramics, specialty alloys), shortening lead times for intricate parts while meeting miniaturization and high-integration demands for semiconductor parts suppliers. By eliminating multi-fixturing defects, it enhances semiconductor equipment reliability and production efficiency.

Why Choose Zhihui Precision

Zhihui Precision can provide you with precision component machining services for semiconductor equipment, backed by years of experience in precision component manufacturing. We have established professional and rigorous confidentiality processes, stringent quality inspection procedures, and a team of over a hundred seasoned technical experts to meet your diverse requirements for high-tech products. Combined with leak testing and anti-oxidation treatment processes, we assist customers in improving the yield of components such as wafer fixtures. Our temperature-controlled and clean machining workshop environment meets the stringent cleanliness requirements of semiconductor production. Leveraging our technical expertise and extensive manufacturing experience, we will provide you with component manufacturing services to achieve cost reduction, efficiency improvement, shortened production cycles, and accelerated project progress.

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文