Zhihui Precision specializes in providing high-precision 5-axis CNC machining services for the robotics industry, utilizing 5-axis simultaneous machining technology to achieve accurate forming of complex curved surfaces and precision components, including critical components for robotic arm.

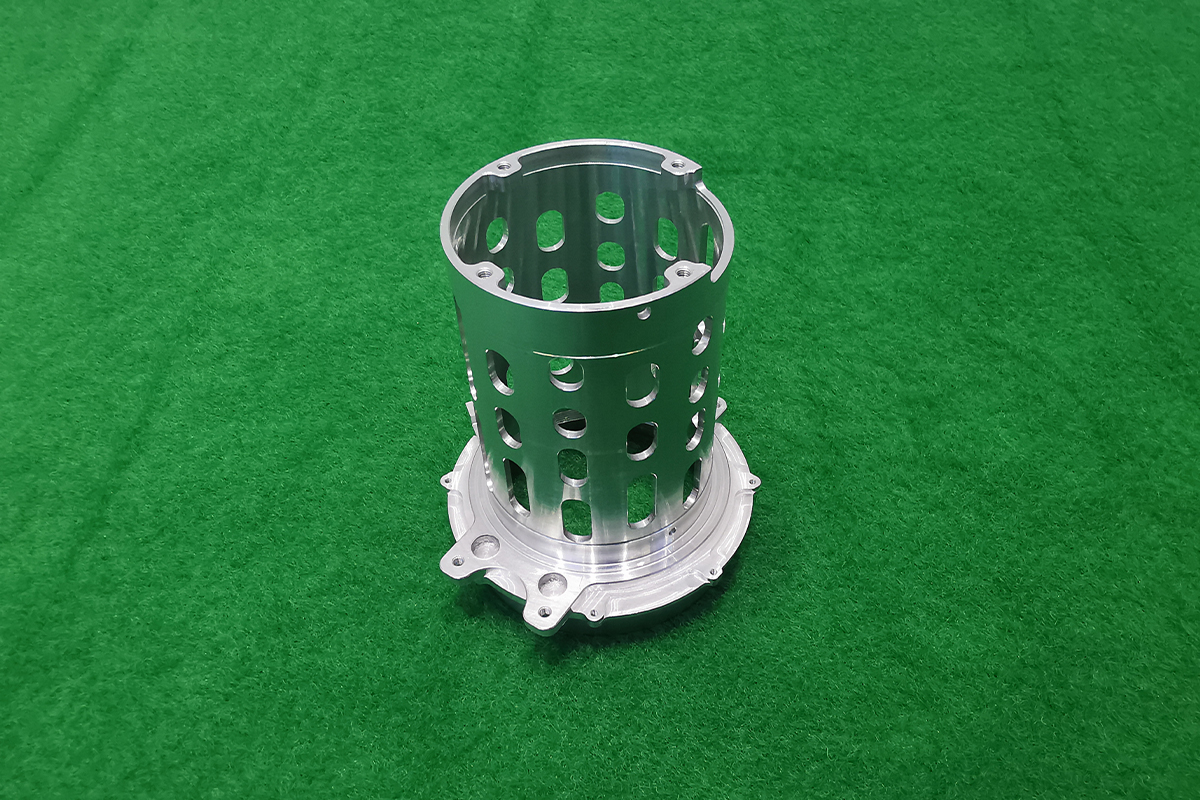

Product Name: Motor Housing

Material: Aluminum Alloy 7075

Dimensions: D 150×200 mm

Manufacturing: 5-axis CNC Machining Service

Product Features:

Precision-machined using our 5-axis CNC technology, this product overcomes challenging designs with complex annular structures and multi-hole patterns:

• Breaks traditional machining limitations via 5-axis simultaneous technology

• Achieves single-setup precision for:

• Multi-surface machining

• High-accuracy hole positioning

• Spatial angle challenges

Technical highlights:

✓ Ensures precise hole diameter and position matching

✓ Delivers flawless surface finish with tight tolerances

✓ Completes complex structures in a single operation

Demonstrates 5-axis CNC's dual advantages in complex component manufacturing:

• High efficiency

• Micron-level precision

Types of Robot We Can Manufacturing

5-Axis CNC Machining for the the Robot Industry

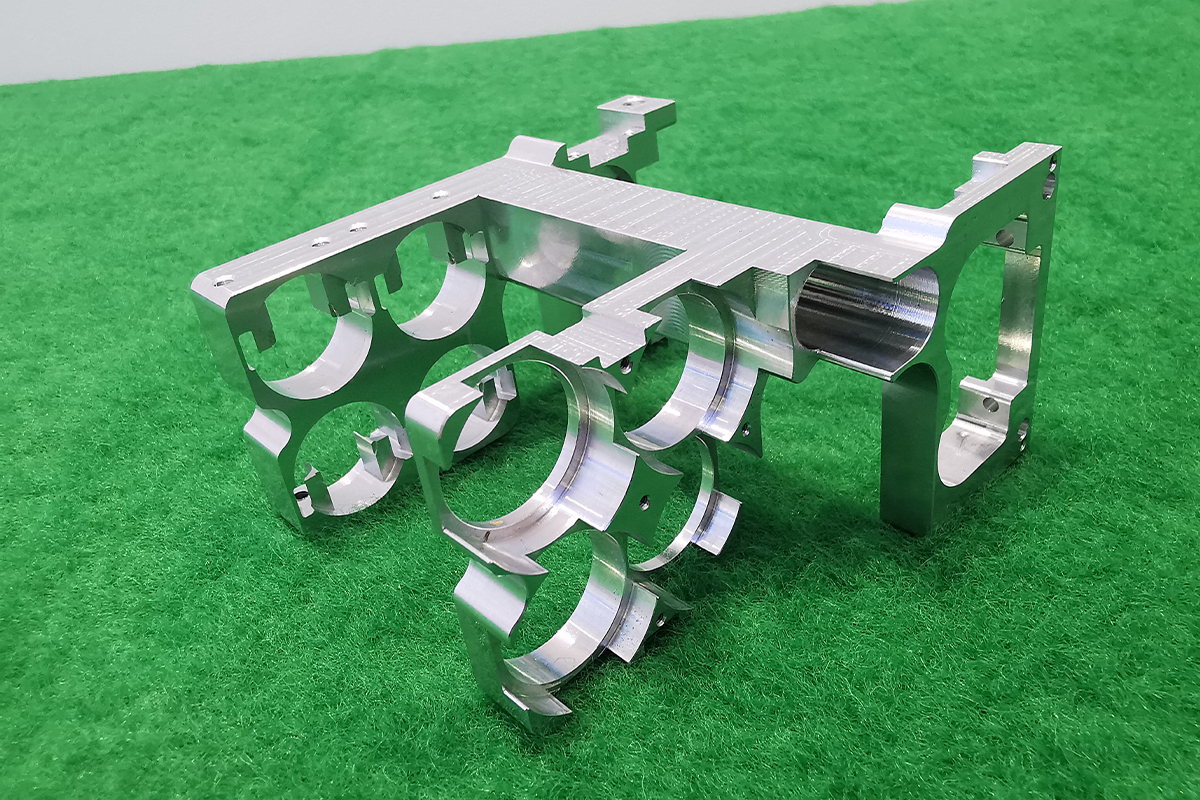

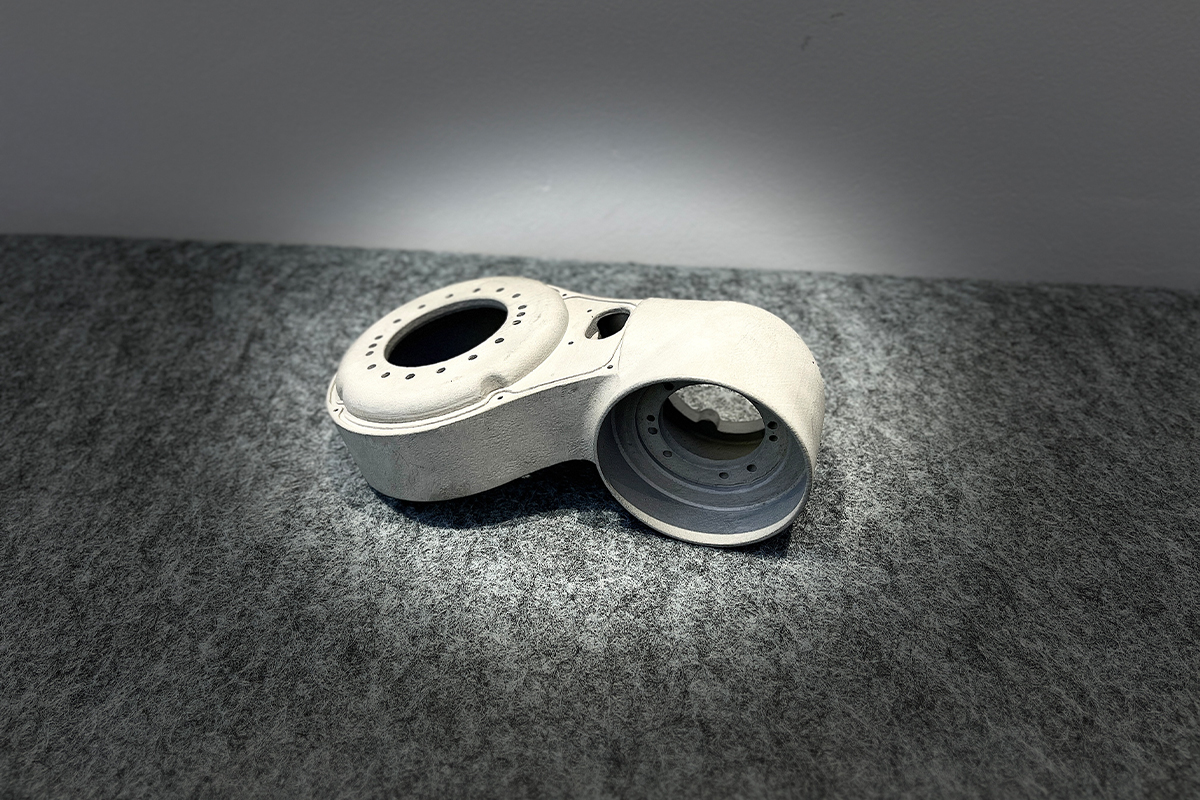

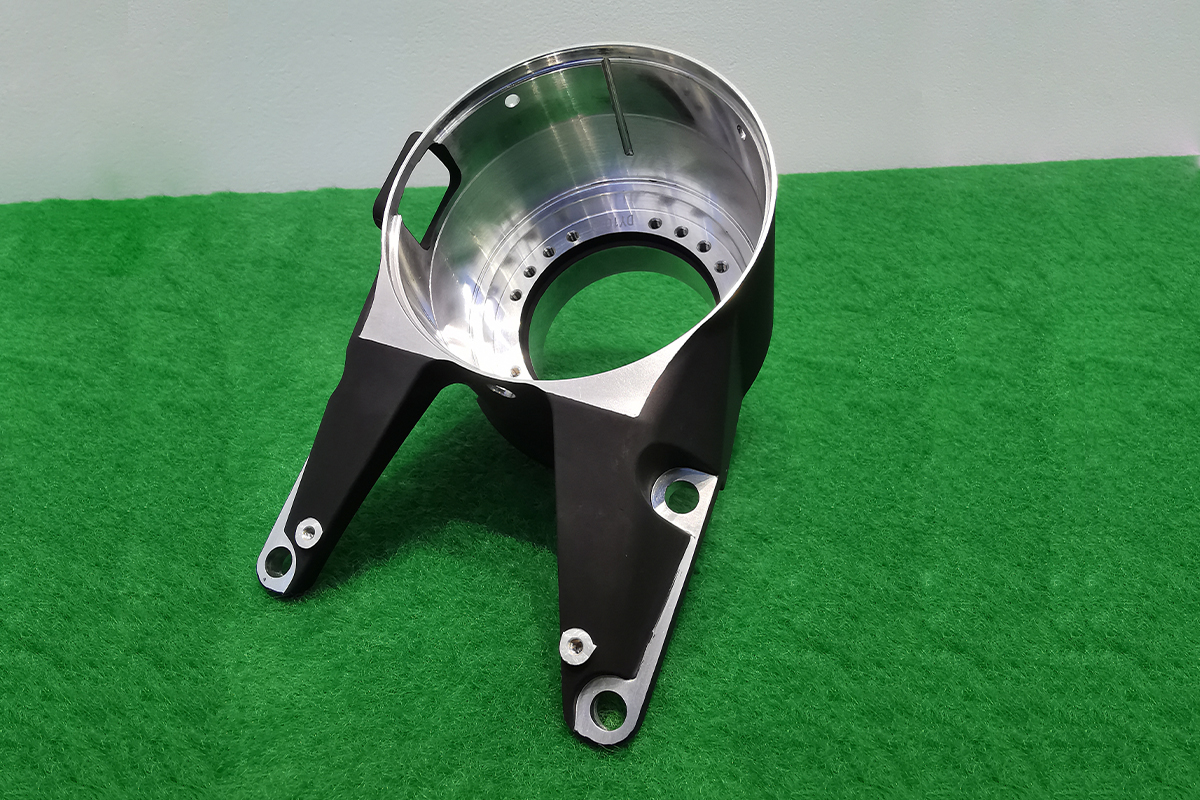

Zhihui Precision specializes in providing high-precision 5-axis CNC machining services for the robotics industry, utilizing 5-axis simultaneous machining technology to achieve accurate forming of complex curved surfaces and precision components. From reducer parts and lightweight robotic arms to joint modules, we help customers improve robots' motion accuracy and stability while optimizing structural designs to reduce weight and energy consumption. With extensive material processing experience (metals/carbon fiber/composites), we ensure the wear resistance and durability of critical components, enabling industrial robots, collaborative robots, and other products to achieve higher levels of repeat positioning accuracy, load capacity and environmental adaptability, providing reliable support for intelligent equipment manufacturing.

Advantages of 5-Axis Machining for the Robotics Industry

5-axis machining technology delivers significant benefits to the robotics sector—particularly for components for robotic arm—through its multi-degree-of-freedom complex surface machining capabilities. It enables high-precision forming of core components such as robotic arm joints and end-effectors, completing multi-surface machining in a single setup to greatly enhance production efficiency.The technology’s dynamic response characteristics ensure superior surface quality and structural strength, meeting the lightweight and high-load design requirements of robotics. Additionally, the flexibility of 5-axis machining supports the development of customized complex structures, accelerating robotic innovation and iteration while providing robust technical support for intelligent equipment manufacturing.

Why Choose Zhihui Precision

With years of experience in manufacturing core components for robots, such as those for Tesla robots, Zhihui Precision has established professional and rigorous confidentiality processes, stringent quality inspection procedures, and a team of over a hundred seasoned technical experts to meet your diverse requirements for high-tech products. Leveraging our technical expertise and extensive manufacturing experience, we will provide you with optimized component design solutions, helping to reduce costs, improve efficiency, shorten production cycles, and accelerate project progress.

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文