Zhihui Precision specializing in 5-axis CNC precision component machining, we provide critical component solutions for the power systems sector through high-precision manufacturing technologies and processes. Power components, often referred to as the "heart" of mechanical equipment, have machining accuracy that directly determines the reliability, efficiency, and energy consumption levels of the equipment.

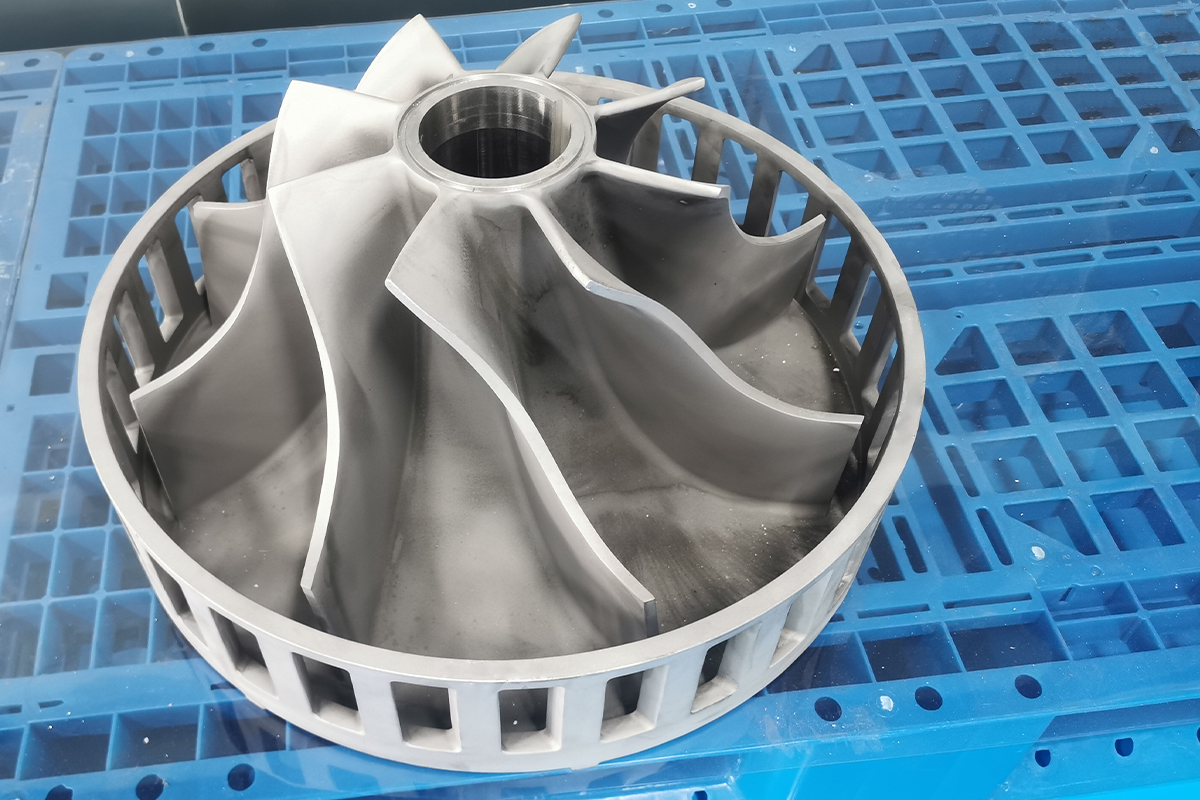

Product Name: Impeller

Material: SUS 304

Dimensions: D 650×450 mm

Manufacturing: 5 axis CNC service

Product Features:

Precision-machined using our 5-axis CNC precision machining technology, this product overcomes challenges such as complex surface forming, thin-wall blade deformation, and stringent precision control. Leveraging 5-axis simultaneous machining capabilities, we achieve high-precision blade contour shaping with seamless surface transitions and minimal dimensional deviations.

The blade profile accuracy and surface finish are meticulously controlled, complemented by dynamic balancing equipment calibration to achieve a balancing precision of <0.1 μm, demonstrating our expertise in high-end precision component manufacturing.

Power Components Products

5-Axis CNC Machining for the Power Components (Impeller) Industry

Zhihui Precision specializes in 5-axis CNC precision component machining, We provide critical component solutions for the power systems sector through high-precision manufacturing technologies and processes. Power components, often referred to as the "heart" of mechanical equipment, have machining accuracy that directly determines the reliability, efficiency, and energy consumption levels of the equipment. Leveraging multi-axis linkage machining technology, we achieve integrated precision machining of complex structures and surfaces, thin-walled structures, and high-strength alloy materials, ensuring the stability of core components such as transmission assemblies and turbine mechanisms under high-speed and high-pressure conditions.

In power systems, components like power impellers, which serve as the core medium for energy conversion, have profile accuracy and dynamic balance performance that determine the efficiency and lifespan of fluid machinery. We employ 5-axis linkage technology to perform integral milling of impellers, optimizing flow channel design and surface treatment processes to achieve higher energy conversion efficiency during the compression and transportation of media, while simultaneously reducing vibration and noise. This technological breakthrough not only enhances the performance metrics of power equipment but also provides foundational support for innovation in fields such as new energy and aerospace.

Through continuous optimization of machining processes and quality control systems, we are committed to becoming a key technical partner in the manufacturing supply chain of power components. By empowering the upgrade of high-end equipment with precision machining, we aim to drive the advancement of efficiency and sustainability in the industrial sector.

Advantages of 5-Axis Machining for the Power Systems Industry

5-axis linkage machining technology demonstrates irreplaceable advantages in the manufacturing of power components: its multi-axis synchronous motion capability enables the precision forming of complex surfaces, overcoming the limitations of traditional machining in structures such as deep cavities, angled holes, and complex curves. This significantly enhances the machining accuracy and surface quality of core components like turbine blades, gearboxes, and complex structural parts. By completing multiple processes in a single setup, it not only reduces repetitive positioning errors but also shortens the production cycle by 30%-50%, meeting the demand for lightweight and high-strength materials in industries such as new energy, aerospace, and related fields. The unique dynamic tool compensation and intelligent path planning of 5-axis technology allow the flow channel design accuracy of fluid components like impellers and pump bodies to reach the micron level, effectively reducing energy consumption by 15%-20% while improving equipment operational stability and lifespan. This technological innovation not only drives power equipment toward higher power density and lower emissions but also serves as a critical enabler for overcoming challenges in high-end manufacturing.

Why Choose Zhihui Precision

With years of experience in manufacturing power system components, Zhihui Precision has established professional and rigorous confidentiality processes, stringent quality inspection procedures, and a team of over a hundred seasoned technical experts to meet your diverse requirements for high-tech products. Leveraging our technical expertise and extensive manufacturing experience, we will provide you with optimized component design solutions, helping to reduce costs, improve efficiency, shorten production cycles, and accelerate project progress.

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文