As a technology enterprise specializing in 5-axis CNC machining, we deliver comprehensive manufacturing solutions for the medical industry - from complex surgical instruments and implants to core components of advanced medical equipment—all powered by the high-precision advantages of multi-axis synchronized machining that define our precision cnc medical machining services.

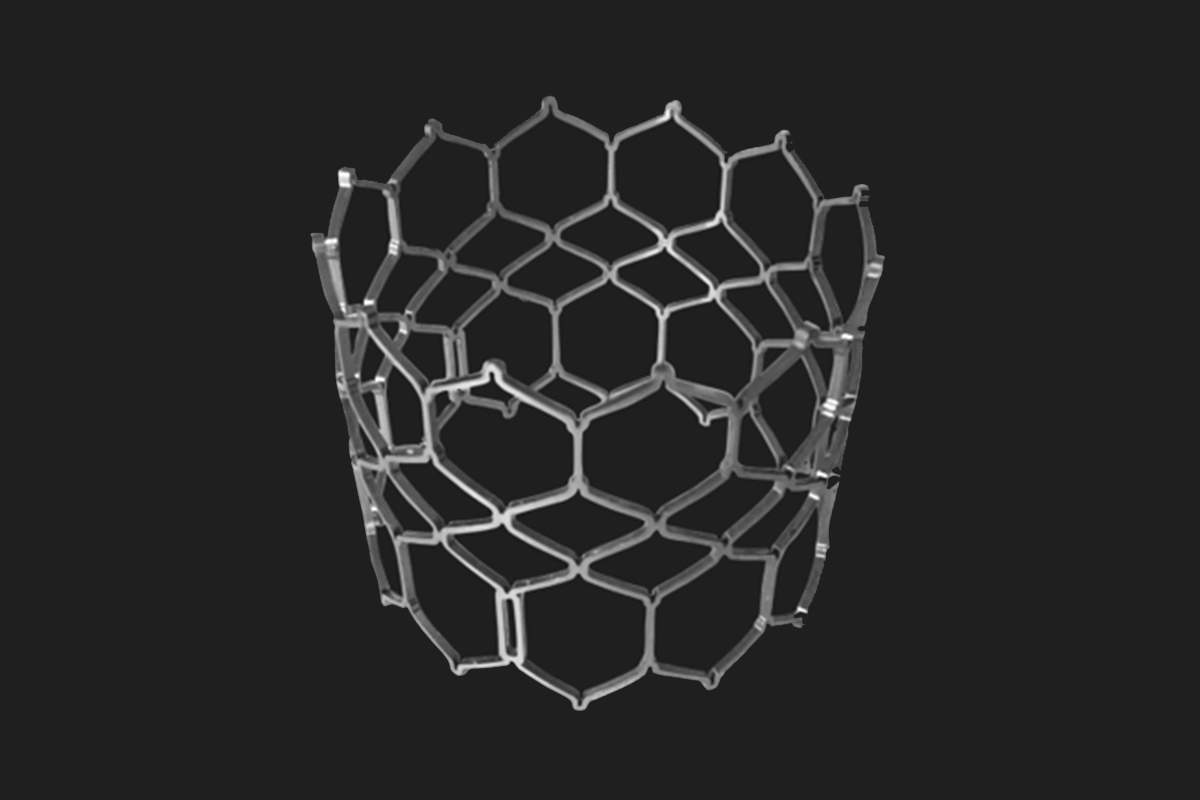

Product Name: Cardiac Stent Functional Test Piece

Material: 316L Stainless Steel

Dimensions: 26.0×26.0×20.0mm

Manufacturing: 5-axis CNC Machining Service

Product Features:

Precision-machined using our 5-axis CNC technology, this product overcomes complex spatial structure machining challenges:

• Achieves uniform surface grid width through 5-axis synchronized precision control

• Solves multi-surface cooperative machining accuracy requirements

• Attains ultra-fine surface roughness of Ra<0.08μm

Demonstrates 5-axis CNC's technical superiority in complex component processing, showcasing exceptional standards from precision forming to surface quality in high-end manufacturing tailored for cnc machining for medical industry.

Types of Medical We Can Manufacturing

5-Axis CNC Machining for the the Medical Industry

As a technology enterprise specializing in 5-axis CNC machining, we deliver comprehensive manufacturing solutions for the medical industry - from complex surgical instruments and implants to core components of advanced medical equipment, all leveraging the high-precision advantages of multi-axis synchronized machining that underpin our precision cnc medical machining services.

Utilizing the multi-dimensional processing capabilities of 5-axis machines, we efficiently manufacture complex geometries, thin-walled components, and micro-features that challenge conventional processes, while ensuring full compliance with ISO 13485 standards, a critical requirement for medical cnc machining services.

Through stringent process controls and precision inspection technologies, we enable clients to:

• Accelerate development cycles

• Enhance product performance

• Drive continuous innovation in life sciences

We provide reliable manufacturing assurance for the advancement of medical devices and healthcare technologies, supporting:

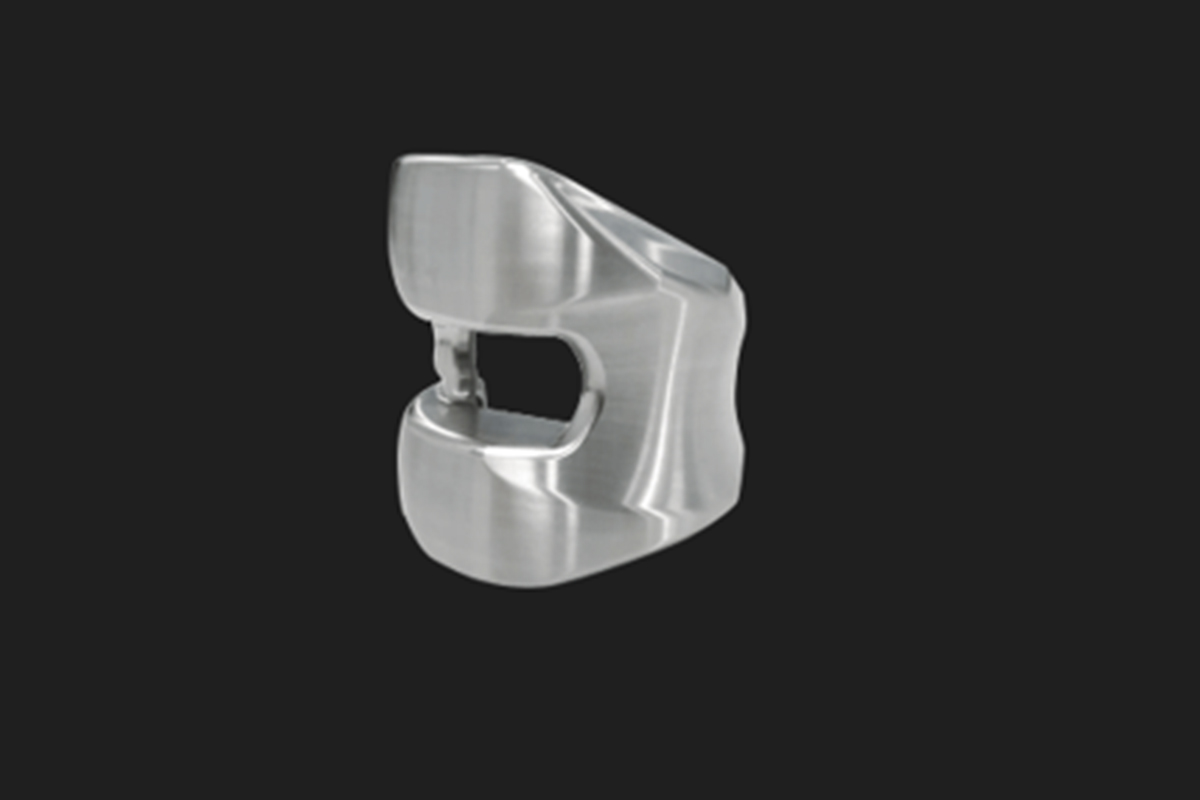

✓ Next-generation surgical tools with micron-level (±0.005mm) accuracy

✓ Patient-specific implants with biocompatible materials (Ti, PEEK, etc.)

✓ Miniaturized components for minimally invasive applications

Advantages of 5-Axis Machining for the Medical Industry

5-axis CNC machining technology offers significant benefits to the medical sector—at the core of cnc machining for medical industry. Its high precision and multi-axis synchronization capabilities enable efficient processing of complex surfaces and intricate structures, meeting stringent geometric accuracy requirements for implants, surgical instruments, and other medical products.

The technology adapts flexibly to special materials like titanium alloys and PEEK, ensuring both biocompatibility and mechanical performance. By reducing setup changes and integrating processes, it significantly improves production efficiency while minimizing error accumulation. Additionally, it supports personalized and customized production, accelerating the development and clinical translation of innovative medical devices—ultimately enabling medical cnc machining services to deliver safer, more precise diagnostic and therapeutic solutions for patients.

Why Choose Zhihui Precision

With years of experience in manufacturing precision medical components, Zhihui Precision has established professional and rigorous confidentiality processes, stringent quality inspection procedures, and a team of over a hundred seasoned technical experts to meet your diverse requirements for high-tech products. We strictly adhere to medical industry cleanliness standards (residual particles ≤5μm). Leveraging our technical expertise and extensive manufacturing experience, we will provide you with optimized component design solutions, helping to reduce costs, improve efficiency, shorten production cycles, and accelerate project progress.

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文