As a precision-focused 5-axis CNC machining provider, we deliver advanced multi-axis machining solutions for critical automotive components.

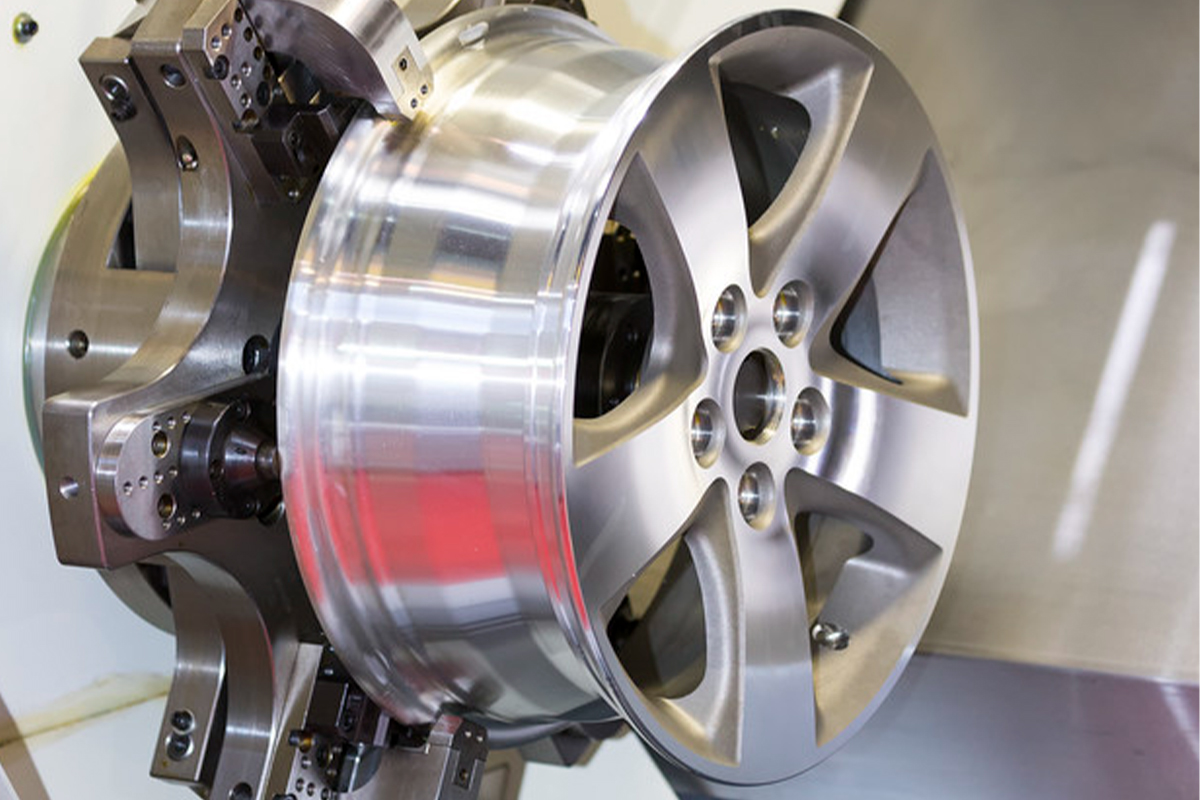

Product Name: Wheel Hub

Material: Aluminum Alloy 6061

Dimensions: D 500×260 mm

Manufacturing: Vertical CNC Turning and Milling + 5-axis CNC Machining Service

Product Features:

Precision-machined using our 5-axis CNC technology, this product exemplifies advanced manufacturing capabilities:

- 5-axis simultaneous machining overcomes challenges in complex hub contour forming and multi-angle precision hole machining

- Single-setup multi-process operation eliminates repositioning errors, ensuring dimensional accuracy and geometric tolerances

- High-degree-of-freedom cutting delivers an exceptional surface finish

Achieves dual breakthroughs in structural precision and process integrity—key to auto parts production and manufacturing automotive components—fully demonstrating 5-axis CNC's technical advantages in efficient, precise and high-quality complex component manufacturing.

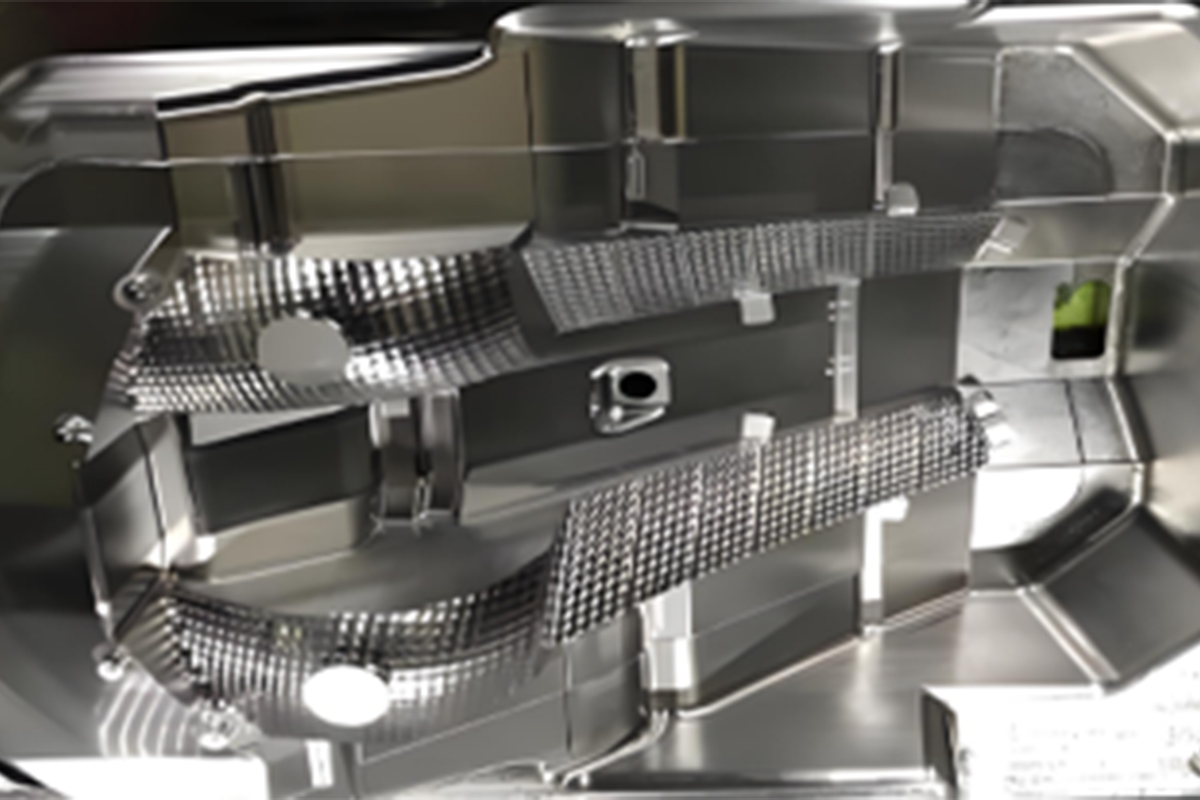

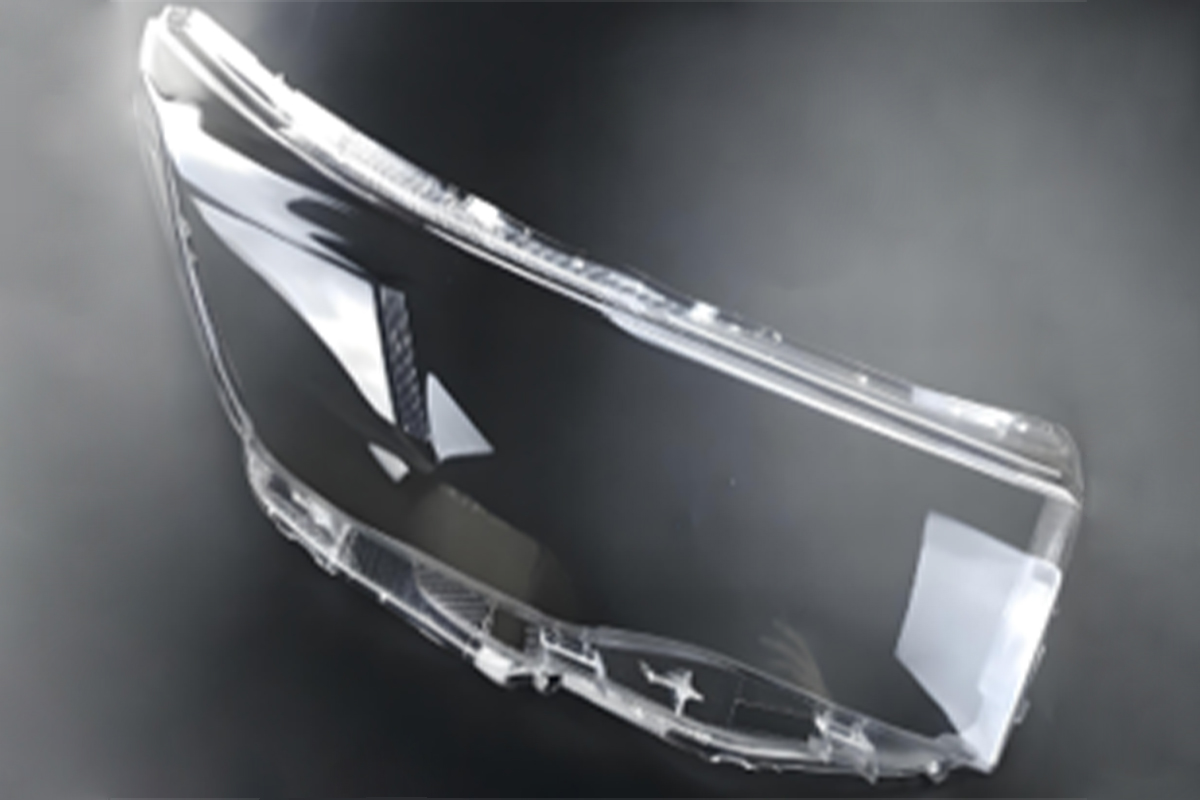

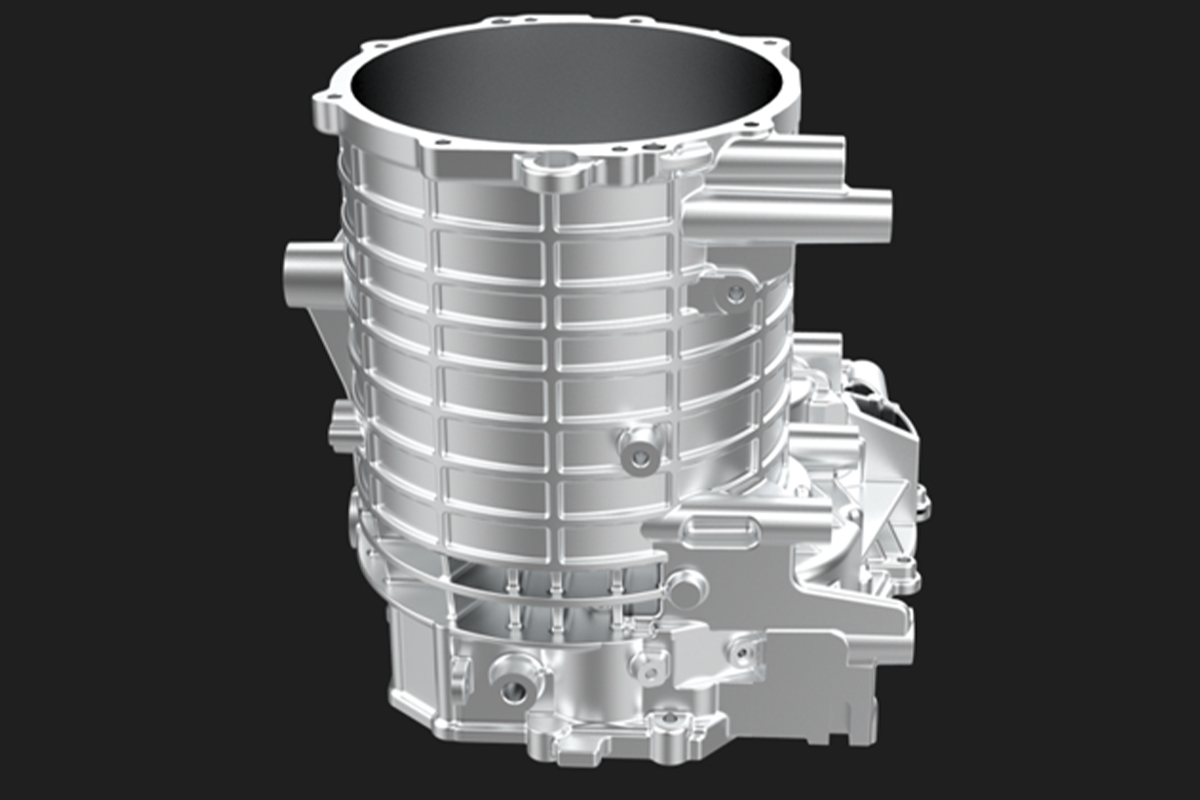

Types of Automotive Parts We Can Manufacturing

Advantages of 5-Axis Machining for the Automotive Industry

5-axis machining offers significant advantages in the automotive sector: Its multi-axis linkage capability enables one-step precision machining of complex curved surfaces, reducing setup times and error accumulation while significantly improving the efficiency and accuracy of critical components such as engine blocks, turbine blades, and intricate structural parts. By flexibly adjusting tool orientation, it efficiently processes hard-to-reach features like deep cavities and angled holes, challenging for traditional methods, and supports the precision forming of high-strength materials in lightweight automotive designs that drive auto parts production and manufacturing automotive components forward.

Additionally, 5-axis machining optimizes cutting paths, minimizing material waste and energy consumption while shortening R&D cycles. It provides high-precision, high-reliability manufacturing solutions for core automotive components, including motor housings and transmissions for new energy vehicles (NEVs), empowering precision automotive parts manufacturers to drive the industry toward smarter, more efficient production.

Why Choose Zhihui Precision

With years of experience in manufacturing power system components, Zhihui Precision has established professional and rigorous confidentiality processes, stringent quality inspection procedures, and a team of over a hundred seasoned technical experts to meet your diverse requirements for high-tech products. Leveraging our technical expertise and extensive manufacturing experience, we will provide you with optimized component design solutions, helping precision automotive parts manufacturers reduce costs, improve efficiency, shorten production cycles, and accelerate project progress.

-

Quality Assurance

Zhihui Precision has obtained ISO 9001:2015 quality management system certification, and certifications for aerospace AS9100 & medical 13485 are currently under application, with relevant certificates expected to be acquired soon.

-

Technical Support

Zhihui Precision has a team of more than one hundred experienced professionals and technicians. Many of them have over 10 years of professional experience in the 5-axis machining and manufacturing industry. Some members of the core management and technical team possess over 15 years of experience in this field.

-

Rapid Delivery

Zhihui Precision is equipped with an advanced MES (Manufacturing Execution System) production management system, developed in-depth collaboration with Beijing Jingdiao Company. With the effective support of the MES system, we have significantly improved product processing efficiency.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文