Industries We Serve

Zhihui Precision is deeply engaged in high-precision industries such as power components (impellers), automotive, aerospace, new energy, medical, robotics, machinery and equipment, semiconductors, ships, etc., and creates high-quality machining services—including tailored precision machining solutions and custom machining solutions—by virtue of superb craftsmanship and technology, as well as large-scale five-axis machining equipment. The main business focuses on five-axis CNC machining of high-precision parts, and empowers various industries to continuously move to new heights in the field of precision manufacturing with excellent quality.

-

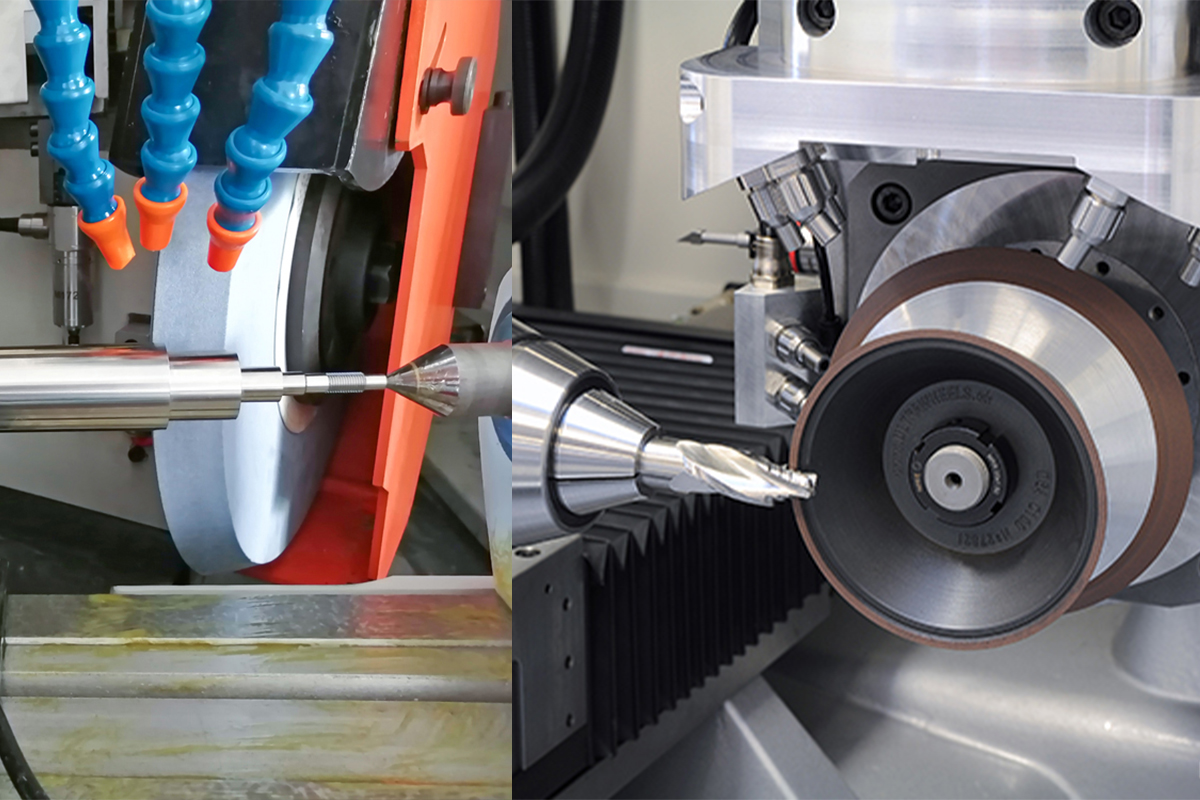

Power Components5-axis CNC machining technology enables high-precision processing of complex surfaces and structures for power components such as impellers, gears, and complex structural parts through multi-axis linkage. It accomplishes multi-face cutting in a single setup, eliminating repetitive positioning errors and ensuring product precision and dimensional consistency. The simplification of processes and improvement in efficiency accelerate the production cycle, facilitating rapid product delivery. The enhanced machining capabilities provide greater design flexibility, effectively supporting the development of innovative structures, optimizing fluid performance and energy efficiency, and offering critical technical support for the advancement of power system manufacturing.

Power Components5-axis CNC machining technology enables high-precision processing of complex surfaces and structures for power components such as impellers, gears, and complex structural parts through multi-axis linkage. It accomplishes multi-face cutting in a single setup, eliminating repetitive positioning errors and ensuring product precision and dimensional consistency. The simplification of processes and improvement in efficiency accelerate the production cycle, facilitating rapid product delivery. The enhanced machining capabilities provide greater design flexibility, effectively supporting the development of innovative structures, optimizing fluid performance and energy efficiency, and offering critical technical support for the advancement of power system manufacturing. -

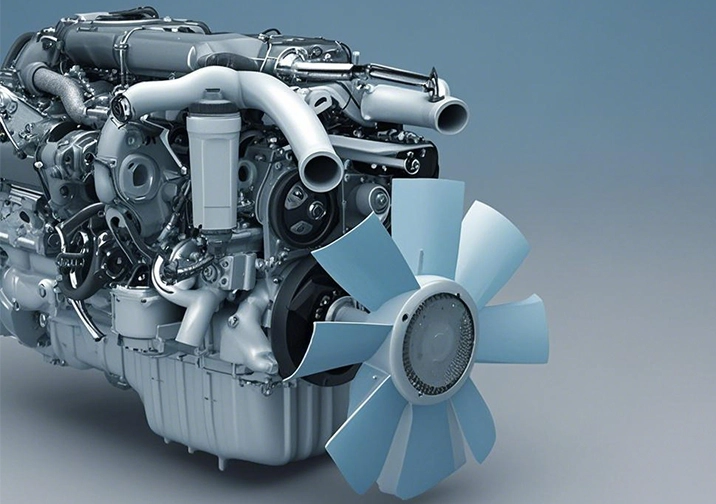

Automotive5-axis CNC precision machining plays a vital role in automotive manufacturing. Its high precision ensures the dimensional accuracy and quality of critical components such as engines, chassis and suspension systems, and transmission assemblies. By completing multiple operations in a single setup, it minimizes errors and shortens production cycles. The flexibility of five-axis CNC enables innovative designs, and we possess extensive machining experience with a wide range of advanced materials, including aluminum/magnesium alloy components and carbon fiber composites. The application of these new materials effectively meets automotive industry demands for light weighting and high performance, thereby enhancing overall vehicle performance and safety.

Automotive5-axis CNC precision machining plays a vital role in automotive manufacturing. Its high precision ensures the dimensional accuracy and quality of critical components such as engines, chassis and suspension systems, and transmission assemblies. By completing multiple operations in a single setup, it minimizes errors and shortens production cycles. The flexibility of five-axis CNC enables innovative designs, and we possess extensive machining experience with a wide range of advanced materials, including aluminum/magnesium alloy components and carbon fiber composites. The application of these new materials effectively meets automotive industry demands for light weighting and high performance, thereby enhancing overall vehicle performance and safety. -

Aviation & Aerospace5-axis CNC precision machining provides robust manufacturing support for the aerospace industry. Leveraging multi-axis simultaneous control, this technology enables highly accurate machining of complex curved surfaces, precision boreholes, and integrated structural components - significantly enhancing the precision and reliability of mission-critical aerospace parts.The 5-axis machining technology demonstrates exceptional capabilities in processing specialized materials, further ensuring the quality and performance of aerospace components. By expanding machining possibilities, it grants engineers greater design freedom and flexibility to develop innovative structures that optimize aerodynamic performance and energy efficiency.This advanced manufacturing approach delivers vital technical support for producing key aerospace components, empowering breakthroughs in both structural innovation and functional performance.

Aviation & Aerospace5-axis CNC precision machining provides robust manufacturing support for the aerospace industry. Leveraging multi-axis simultaneous control, this technology enables highly accurate machining of complex curved surfaces, precision boreholes, and integrated structural components - significantly enhancing the precision and reliability of mission-critical aerospace parts.The 5-axis machining technology demonstrates exceptional capabilities in processing specialized materials, further ensuring the quality and performance of aerospace components. By expanding machining possibilities, it grants engineers greater design freedom and flexibility to develop innovative structures that optimize aerodynamic performance and energy efficiency.This advanced manufacturing approach delivers vital technical support for producing key aerospace components, empowering breakthroughs in both structural innovation and functional performance. -

New Energy5-axis CNC precision machining technology provides highly accurate one-pass processing solutions for the new energy industry. This advanced manufacturing method delivers reliable production assurance for complex surface forming of critical components such as motor and battery housings, generator blades, and other key parts in the renewable energy sector.With its superior structural machining capabilities, the technology effectively supports the application of advanced materials like aluminum alloys and carbon fiber composites, significantly reducing component weight and motor energy consumption. This drives the upgrade of new energy equipment toward higher efficiency and reliability while accelerating the widespread adoption of clean energy technologies.

New Energy5-axis CNC precision machining technology provides highly accurate one-pass processing solutions for the new energy industry. This advanced manufacturing method delivers reliable production assurance for complex surface forming of critical components such as motor and battery housings, generator blades, and other key parts in the renewable energy sector.With its superior structural machining capabilities, the technology effectively supports the application of advanced materials like aluminum alloys and carbon fiber composites, significantly reducing component weight and motor energy consumption. This drives the upgrade of new energy equipment toward higher efficiency and reliability while accelerating the widespread adoption of clean energy technologies. -

Medical5-axis CNC precision machining plays a vital role in medical device manufacturing. Its high-precision capabilities ensure the accurate forming of complex structures and intricate curved surfaces for critical medical products including: Surgical instruments (bone drills, forceps, minimally invasive tools) Implants & prosthetics (artificial joints (hip/knee), dental implants, cranial plates) Minimally invasive devices (integrated machining of endoscopic catheters, robotic surgical joints with micro-channels and precision hinge mechanisms) This technology drives the advancement of medical equipment toward miniaturization and intelligence, particularly breaking through traditional limitations in minimally invasive device manufacturing. It serves as a key enabler for the development of precision medicine technologies by: Achieving micron-level accuracy (±0.005mm) for critical components Enabling complex geometry integration in single setups Supporting biocompatible material processin

Medical5-axis CNC precision machining plays a vital role in medical device manufacturing. Its high-precision capabilities ensure the accurate forming of complex structures and intricate curved surfaces for critical medical products including: Surgical instruments (bone drills, forceps, minimally invasive tools) Implants & prosthetics (artificial joints (hip/knee), dental implants, cranial plates) Minimally invasive devices (integrated machining of endoscopic catheters, robotic surgical joints with micro-channels and precision hinge mechanisms) This technology drives the advancement of medical equipment toward miniaturization and intelligence, particularly breaking through traditional limitations in minimally invasive device manufacturing. It serves as a key enabler for the development of precision medicine technologies by: Achieving micron-level accuracy (±0.005mm) for critical components Enabling complex geometry integration in single setups Supporting biocompatible material processin -

Robot5-axis CNC precision machining achieves high-precision forming of complex structures and intricate curved surfaces for robotic core components - including harmonic drive housings, servo motor casings, and sensor brackets - through multi-axis synchronization and single-setup processing.This technology demonstrates machining capabilities for lightweight materials such as aluminum alloys and carbon fiber composites, effectively advancing robotics toward lightweight design and higher payload-to-weight ratios, while accelerating innovations in smart manufacturing and robotic technologies.

Robot5-axis CNC precision machining achieves high-precision forming of complex structures and intricate curved surfaces for robotic core components - including harmonic drive housings, servo motor casings, and sensor brackets - through multi-axis synchronization and single-setup processing.This technology demonstrates machining capabilities for lightweight materials such as aluminum alloys and carbon fiber composites, effectively advancing robotics toward lightweight design and higher payload-to-weight ratios, while accelerating innovations in smart manufacturing and robotic technologies. -

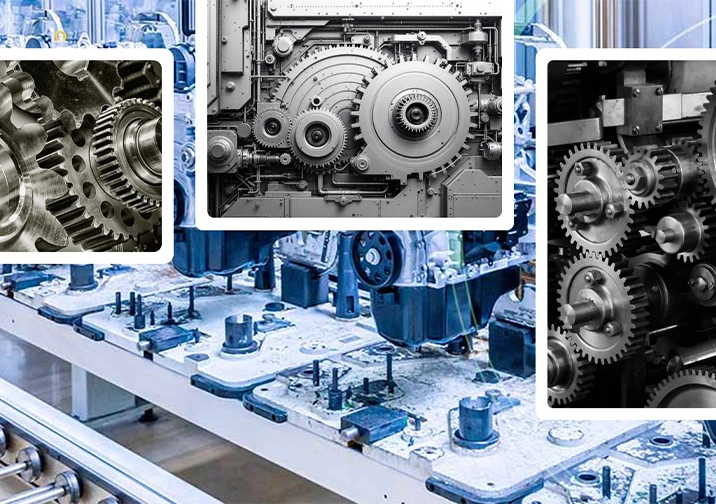

Mechanical Equipment5-axis CNC precision machining enables precise forming of mechanical core components (such as high-precision gears, pump bodies, valve bodies, and complex transmission mechanisms), significantly improving transmission accuracy and structural reliability. This technology breaks through traditional limitations in manufacturing high-end bearings, precision molds, and fluid control equipment, driving mechanical equipment toward lightweight design and higher load-to-weight ratios while accelerating innovations in industrial automation and intelligent equipment technology.

Mechanical Equipment5-axis CNC precision machining enables precise forming of mechanical core components (such as high-precision gears, pump bodies, valve bodies, and complex transmission mechanisms), significantly improving transmission accuracy and structural reliability. This technology breaks through traditional limitations in manufacturing high-end bearings, precision molds, and fluid control equipment, driving mechanical equipment toward lightweight design and higher load-to-weight ratios while accelerating innovations in industrial automation and intelligent equipment technology. -

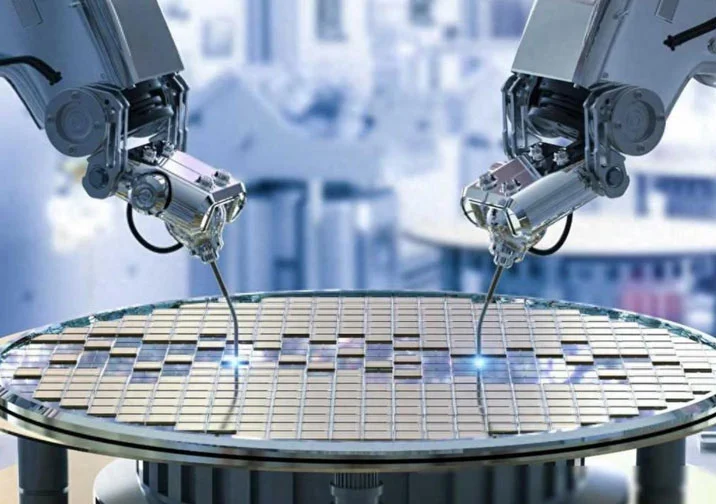

Semi-conductor5-axis CNC precision machining is crucial for semiconductor component manufacturing, enabling high-precision and highly efficient processing of intricate parts.This technology is particularly suitable for hard materials, meeting the stringent requirements of semiconductor equipment for precision structural components, thereby enhancing the overall reliability and production efficiency of chip manufacturing.

Semi-conductor5-axis CNC precision machining is crucial for semiconductor component manufacturing, enabling high-precision and highly efficient processing of intricate parts.This technology is particularly suitable for hard materials, meeting the stringent requirements of semiconductor equipment for precision structural components, thereby enhancing the overall reliability and production efficiency of chip manufacturing. -

Shipbuilding5-axis CNC precision machining enables efficient processing of complex curved surfaces, improving part accuracy and consistency while reducing processing steps and assembly difficulty. This technology enhances production efficiency and safety performance, lowers manufacturing costs, and meets the shipbuilding industry's requirements for high-strength, corrosion-resistant components - ultimately optimizing overall vessel performance.

Shipbuilding5-axis CNC precision machining enables efficient processing of complex curved surfaces, improving part accuracy and consistency while reducing processing steps and assembly difficulty. This technology enhances production efficiency and safety performance, lowers manufacturing costs, and meets the shipbuilding industry's requirements for high-strength, corrosion-resistant components - ultimately optimizing overall vessel performance.

Compared to other peers in China, Zhihui Precision exclusively specializes in 5-axis CNC precision product machining. Our dedication fosters expertise, making us your ideal choice for a 5-axis parts machining manufacturer that excels in reliable precision machining solutions.

Zhihui Precision has long been dedicated to the field of high-precision, high-quality 5-axis CNC product machining, specializing in tailored custom machining solutions. We consistently address complex machining challenges for our clients, and our team has accumulated extensive manufacturing experience in the process. This wealth of experience provides a strong technical foundation for effective cost control.

Thanks to our extensive production equipment (Largest 5-axis CNC Machining Manufacturer in South of China with 56sets 5-axis CNC machines) and a skilled technical and management team, we are always able to offer rapid delivery cycles for our clients' projects, helping them gain a competitive edge in the market.

Thanks to our experienced team of project engineers and well-established management processes (including MES system), we are able to maintain swift communication and responsiveness between clients and internal departments, ensuring consistently efficient progress for our clients' projects.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文