-

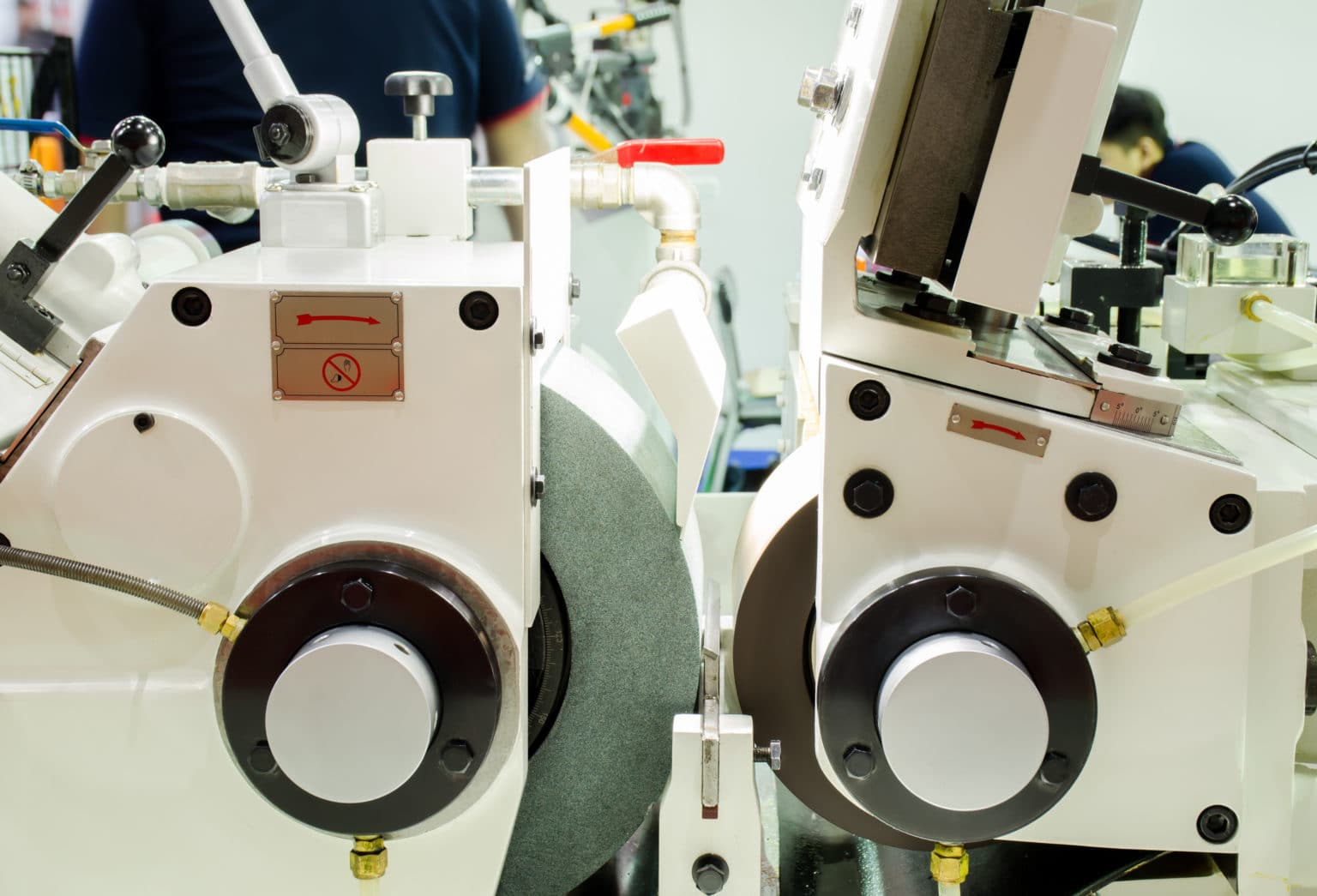

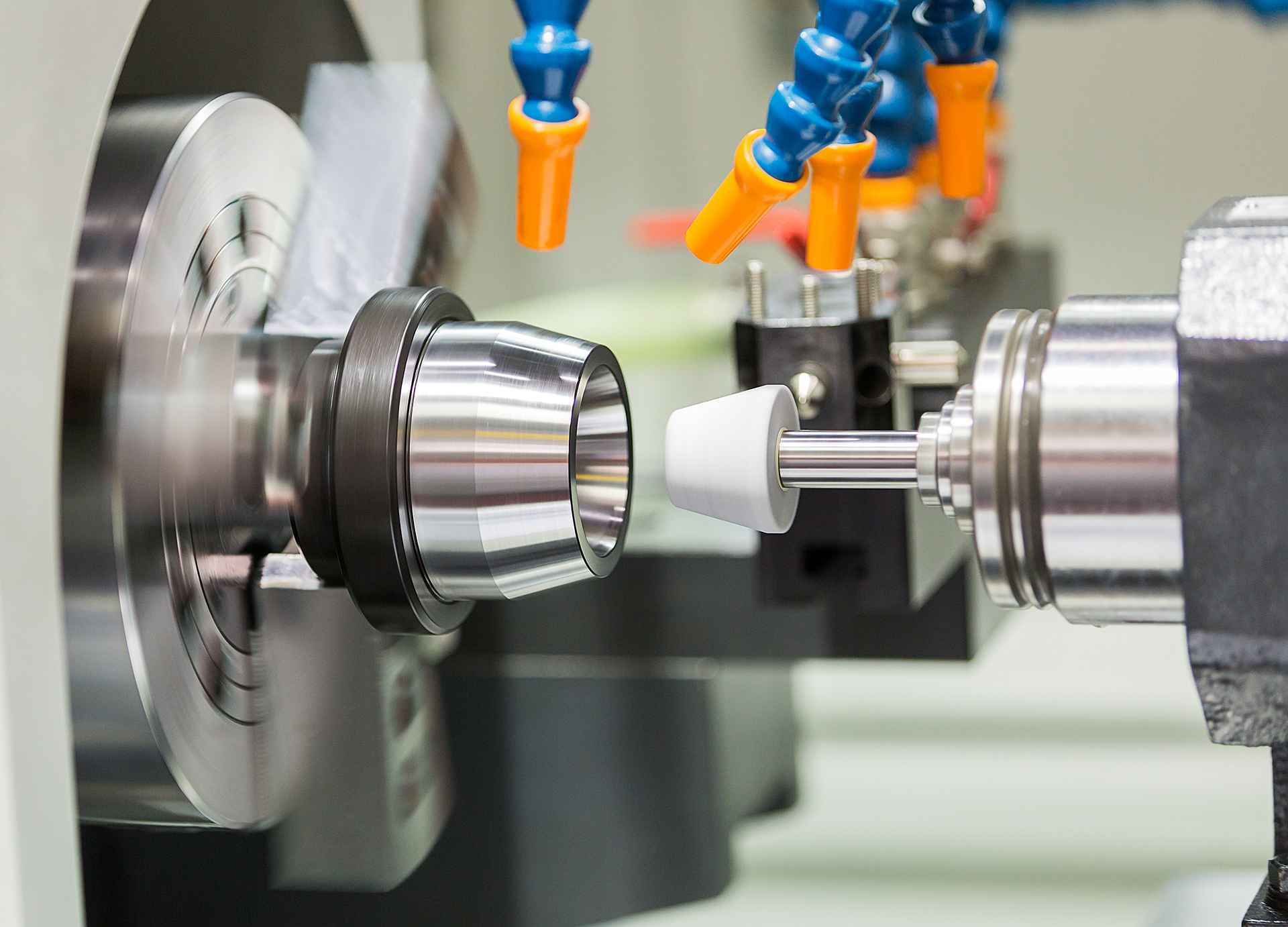

Precision Grinding Machining

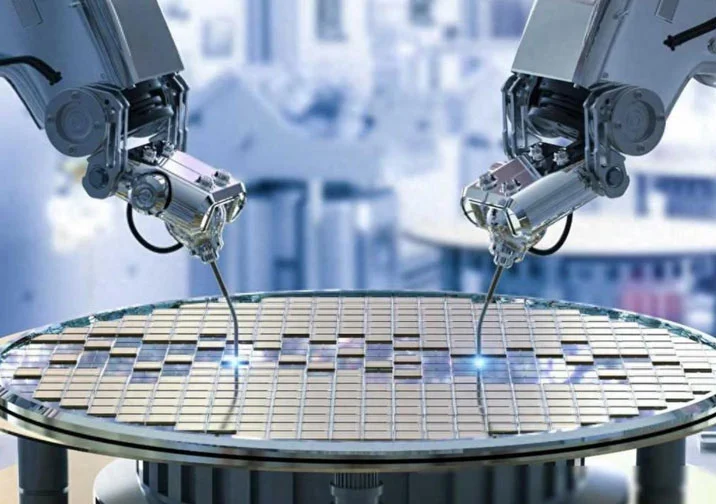

Zhihui Precision for better align with and meet customer demands, Zhihui Precision has equipped itself with grinding machines. This comprehensive setup enables us to better serve our clients with professional precision surface grinding services and manufacture a wide array of complex products.

Providing precision Grinding Machining with a tolerance of 0.001mm:

Custom manufacturing of metal parts from prototyping to mass production

Prototype design within 3-5 days and mass production within 1-2 weeks

CNC Turning-Milling machining and forming of precision metal parts

Zhihui Precision is ISO 9001 Certified Factory, Aerospace AS9100 and Medical 13485 certifications in progress;

±0.001mm and above precision requirements can be processed

Precision Grinding Machining Overview

Overview of Precision Grinding

Precision grinding is a high-precision manufacturing process primarily used for fine machining of workpiece surfaces to achieve extremely high dimensional accuracy, shape accuracy, and surface finish. Grinding machines use high-speed rotating grinding wheels to remove trace (element) material, making them suitable for machining hard materials such as hardened steel, carbide, and ceramics—ideal for delivering the rigorous standards of precision surface grinding services.

Key Features:

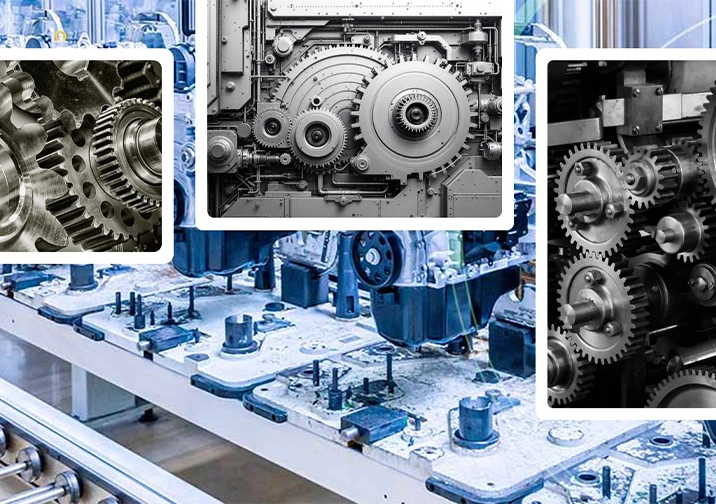

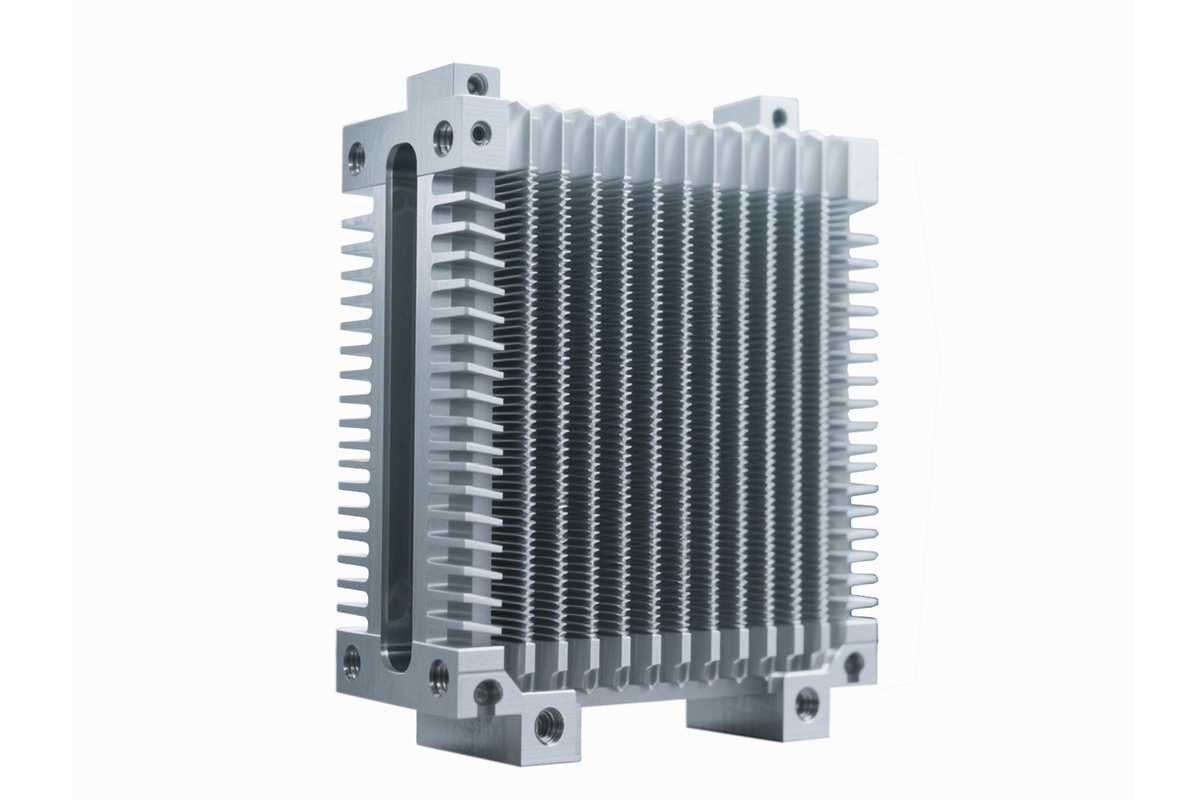

1. High Precision: Precision grinding can achieve machining accuracy at the micron or even sub-micron level, meeting the demands of high-precision parts. 2. Superior Surface Quality: By selecting appropriate grinding wheels and optimizing machining parameters, extremely low surface roughness (Ra value) can be achieved. 3. Wide Applicability: Suitable for machining various hard materials and complex shapes, such as internal and external cylinders, flat surfaces, curved surfaces, and threads. 4. High Automation: Modern precision grinding machines are often equipped with CNC systems, enabling automated machining and improving production efficiency and consistency.

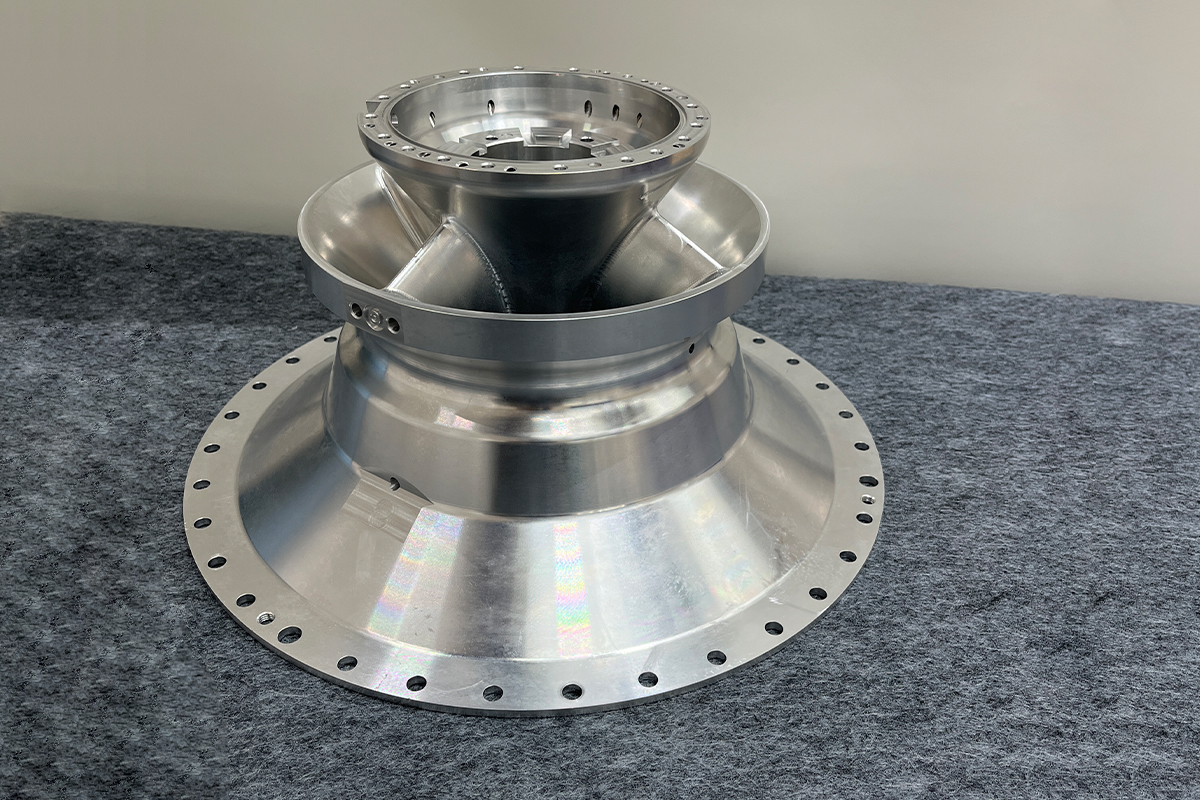

Applications: • Aerospace: High-precision engine components, turbine blades, etc. • Automotive Manufacturing: Critical components such as bearings, gears, and crankshafts. • Mold Manufacturing: Surface machining of precision molds. • Medical Devices: High-precision surgical instruments and implants.

Advantages: • Capable of machining extremely hard materials. • Provides exceptional dimensional and shape accuracy. • High surface finish, reducing the need for machining. • Suitable for high-volume and high-precision production.

Precision grinding is an indispensable technology in modern manufacturing, playing a critical role in fields requiring high precision and superior surface quality.

Benefits of Precision Grinding Machining

The Grinding Machining is the most important process in the manufacturing Industry today.

Grinding Benefit:

Obtain a good surface finish on the workpiece.

Can machine very hard materials.

High Precision and Accuracy

Consistency and Reproducibility

Low heat, minimizing stress and thermal damage to the workpiece.

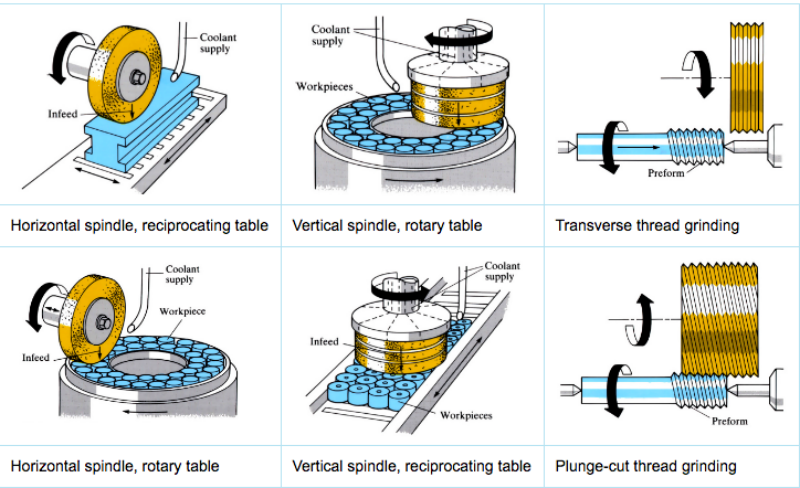

The following are different types of operations that can be performed on grinding:

Surface Grinding Operation

Cylindrical Grinding Operation

Thread grinding Operation

Internal and External Grinding

Centerless Grinding

Form Grinding Operation

Wet and Dry Grinding Operation.

Why Choose Zhihui Precision CNC Machining Services

We operate over 50 CNC machining centers, including more than 40 five-axis CNC machining centers, providing ample production capacity to handle batch orders simultaneously and ensuring short lead times for customer projects.

Our five-axis machining centers are designed with optimal and high-performance structures, achieving machining accuracy of ±0.002mm.

We employ experienced project managers with fluent English communication skills, enabling effective collaboration with customers and ensuring the quality and delivery timelines of their projects are meticulously managed.

Our adoption of the MES digital management system guarantees effective control over every production process.

We strictly adhere to a quality control system that oversees every stage of preparation, manufacturing, and inspection, ensuring that the quality of our five-axis CNC machined parts consistently meets requirements.

Through efficient management and continuous innovation in manufacturing technology, we consistently improve production efficiency and accuracy. This allows us to offer highly competitive pricing and exceptional service experiences while maintaining fast turnaround times and timely deliveries.

Material We Use

| Aluminum | Steel | Stainless steels | Copper | High Temperature Alloys |

| 6061, 6061-T6 | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36 | SUS201 | Brass: C27400, C28000, C36000 | Titanium Alloy TC4/Ti-6AI4V |

| 7075, 7075-T6 | Die steel: M238, S7. | 2205 | Bronze: Tin Bronze | Titanium Alloy TA1 |

| 2024 | Alloy steel | SUS303 | Beryllium copper | Titanium Alloy TA2 |

| 5052 | High-speed steel | SUS304 | Copper C101 (T2) | Magnesium Alloy AZ31B |

| 5083 | Cold rolled steel | SUS316 | Copper C103 (T1) | Magnesium Alloy AZ91 |

| 6063 | Bearing steel | SUS316L | Copper C103 (TU2) | Nickel |

| 6082 | Spring steel | SUS420 | Copper C110 (TU0) | |

| AL6013 | SUS430 | |||

| Fixture Aluminum | SUS431 | |||

| ADC12 (A380) | SUS440C | |||

SUS630/17-4PH/15-5PH | ||||

AISI304 | ||||

| 3Cr13, GCr15, |

Precision Machining Applications Industry

Widely used in industries such as aerospace, Automotive, Medical Equipment, New Energy, Robot& Surgical Robot, Semi-conductor, oil and gas, Food Processing, Mechanical equipment, Mining, Power Generation, and Transportation.

Ideal for manufacturing components like turbine blades, propellers, and orthopedic implants.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文