-

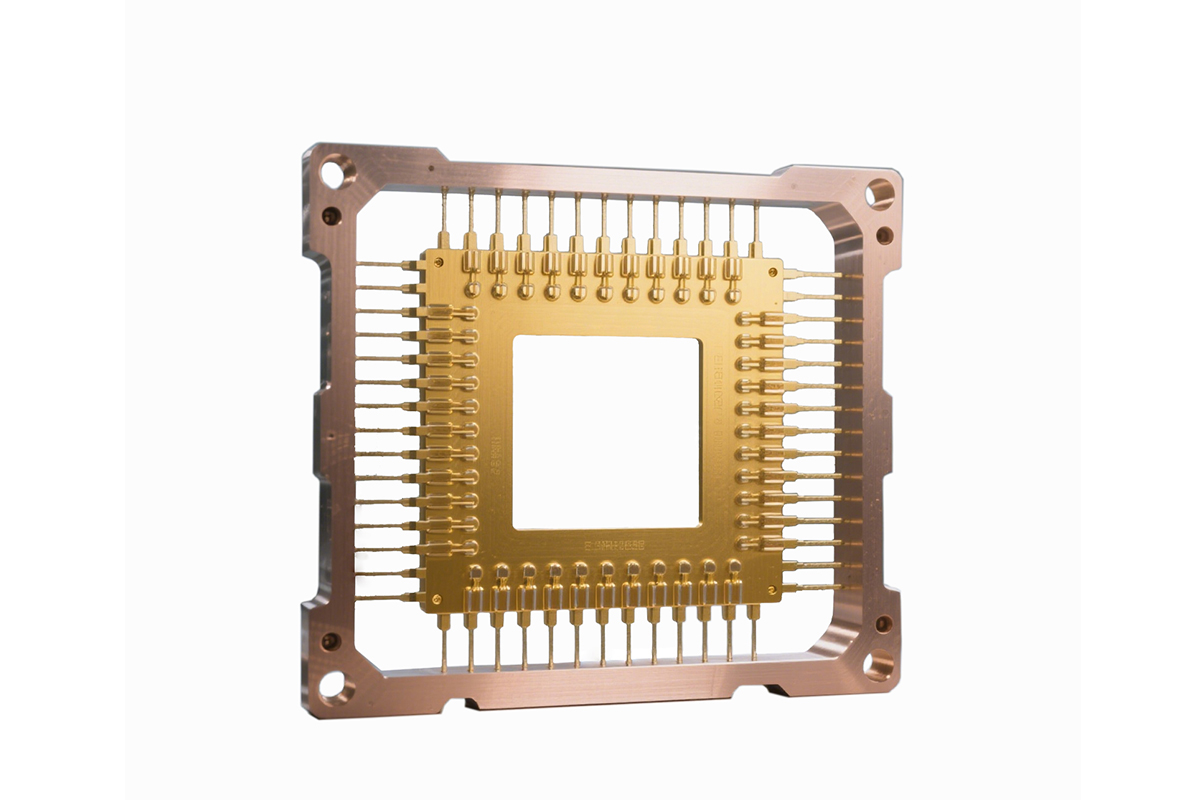

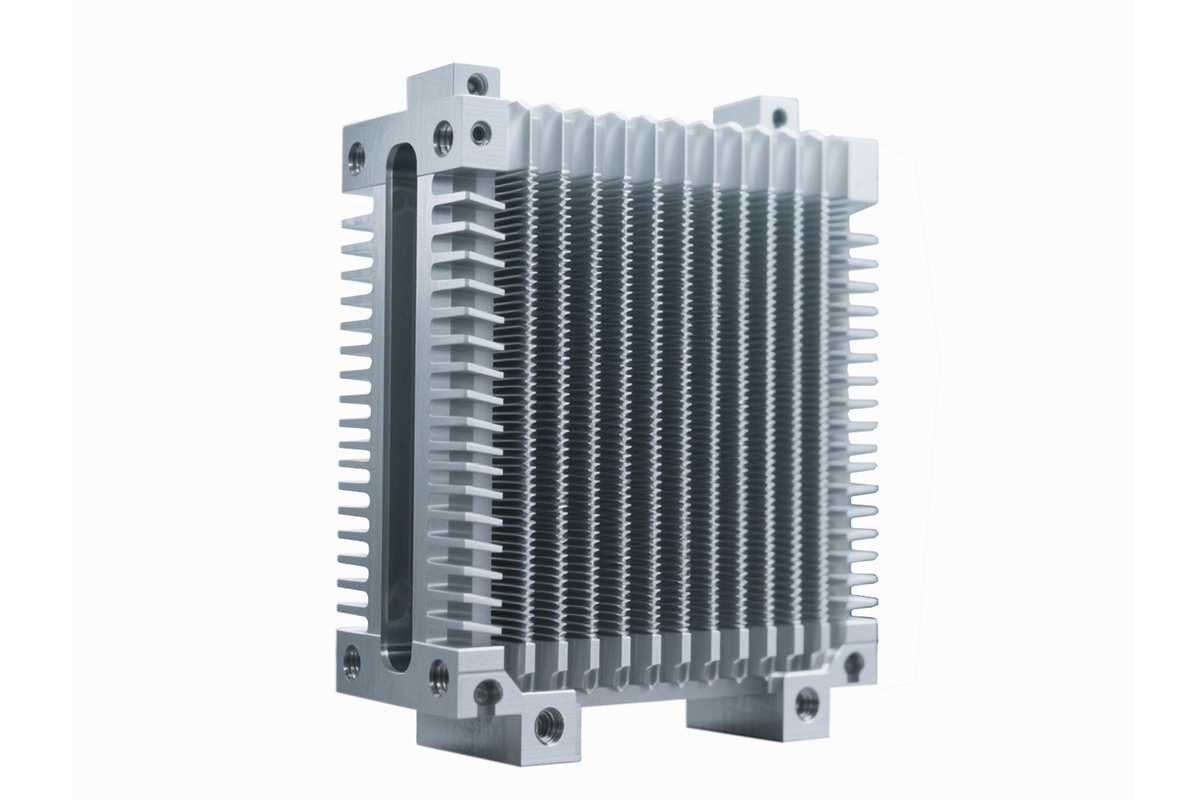

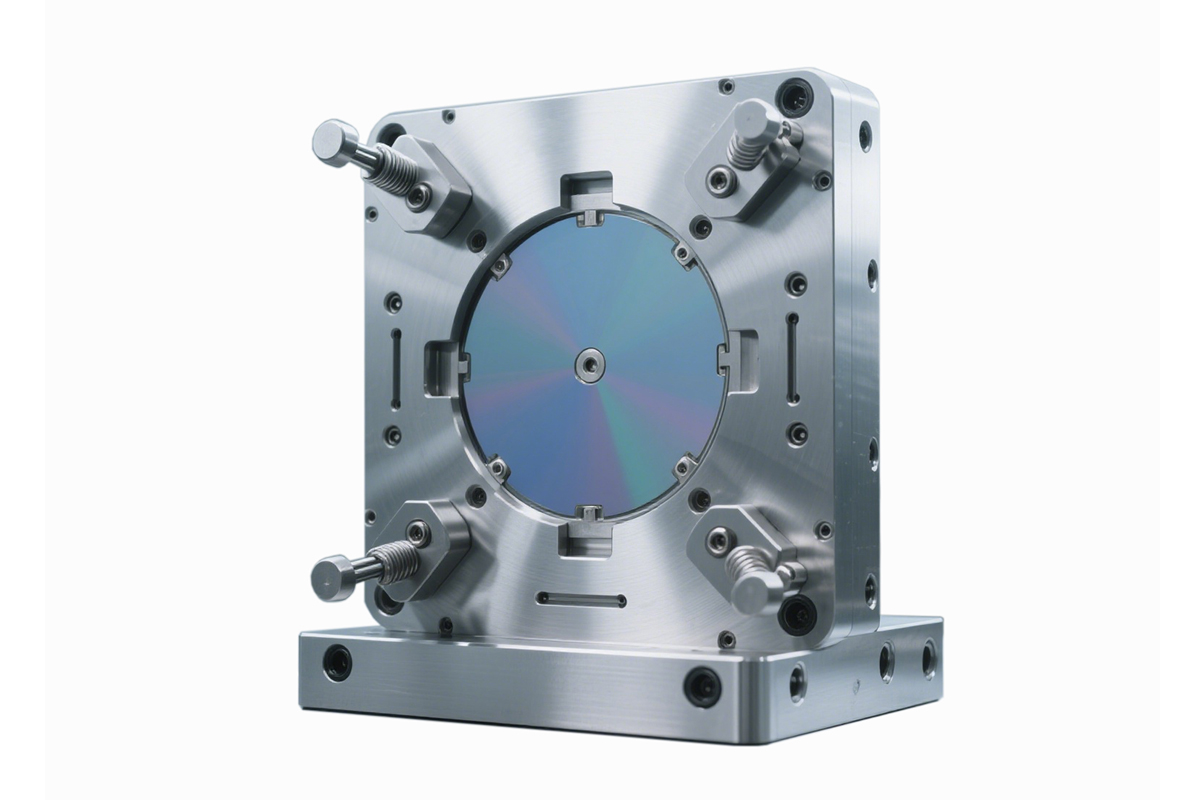

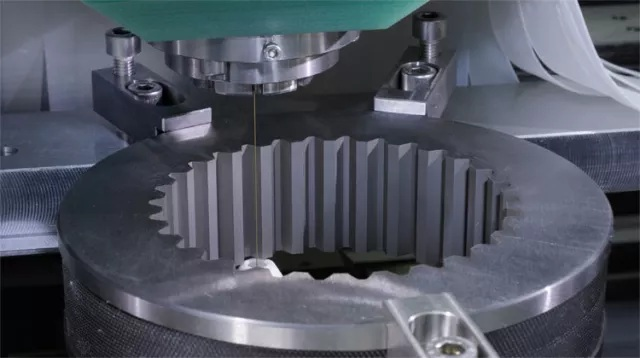

Precision EDM & Wire-cutting Machining

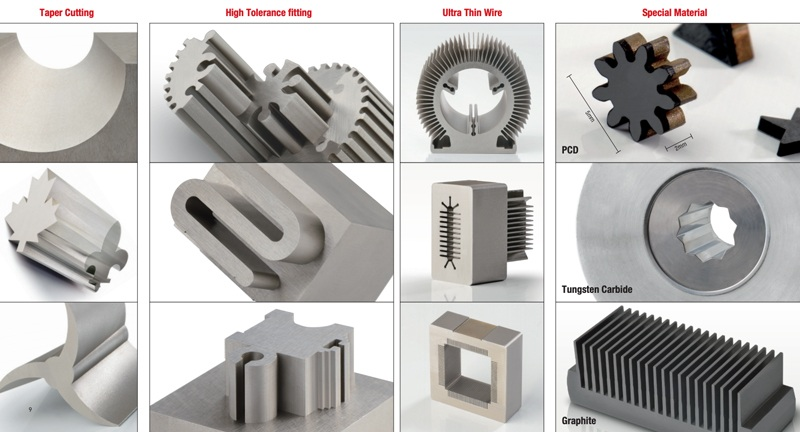

Zhihui Precision for better align with and meet customer demands, Zhihui Precision has equipped itself with EDM & Wire-cutting Machining machines—specialized for high-precision wire edm manufacturing. This comprehensive setup enables us to better serve our clients and manufacture a wide array of complex products.

Providing precision EDM & Wire-cutting Machining with a tolerance of 0.001mm;

Custom manufacturing of metal parts from prototyping to mass production

Prototype design within 3-5 days and mass production within 1-2 weeks

CNC Turning-Milling machining and forming of precision metal parts

Zhihui Precision is ISO 9001 Certified Factory, Aerospace AS9100 and Medical 13485 certifications in progress;

±0.001mm and above precision requirements can be processed

Precision EDM & Wire-cutting Machining Overview

EDM and Wire cutting centers.

Electrical Discharge Machining (EDM) and Wire EDM are two of the most common machining methods used in industrial manufacturing today. Both processes involve using electricity to cut metal parts, but there are some essential differences between them that should be considered when choosing a method.

We also offer EDM and Wire EDM parts machining, specializing in wire edm manufacturing and providing complete machining guarantees for parts with multiple processes and complexity.

Benefits of Precision EDM & Wire-cutting Machining

Advantages of Precision EDM and Slow Wire-Cut CNC Machining Centers:

Precision EDM (Electrical Discharge Machining) and slow wire-cut CNC machining centers—trusted by professional wire edm manufacturers—are advanced technologies in modern manufacturing used for machining complex shapes and high-precision components. They utilize the principle of spark erosion for material removal and are suitable for precision machining of conductive materials.

Advantages of EDM Discharge Machining:

Complex shape machining: Capable of machining complex geometric shapes and fine features that are difficult to achieve with traditional mechanical machining.

Non-contact machining: The tool and workpiece do not directly contact during the machining process, reducing the risk of mechanical stress and deformation.

High precision: Can achieve machining precision at the micron level, meeting the manufacturing needs of high-precision parts.

Material diversity: Suitable for machining various hard alloys and conductive materials.

Advantages of Slow Wire-Cut CNC Machining Centers:

High-precision cutting: Uses a thin wire electrode to achieve high-precision cutting with smooth cuts, and precision can reach the micron level.

Complex contour machining: Can accurately cut complex contours and small gaps, suitable for the manufacture of precision molds and parts.

High degree of automation: CNC systems enable automated machining, improving production efficiency and consistency.

Good surface quality: The machined workpiece has a high surface quality, reducing the need for subsequent machining.

Why Choose Zhihui Precision CNC Machining Services

We operate over 50 CNC machining centers, including more than 40 five-axis CNC machining centers, providing ample production capacity to handle batch orders simultaneously and ensuring short lead times for customer projects.

Our five-axis machining centers are designed with optimal and high-performance structures, achieving machining accuracy of +/- 0.002mm.

We employ experienced project managers with fluent English communication skills, enabling effective collaboration with customers and ensuring the quality and delivery timelines of their projects are meticulously managed.

Our adoption of the MES digital management system guarantees effective control over every production process.

We strictly adhere to a quality control system that oversees every stage of preparation, manufacturing, and inspection, ensuring that the quality of our five-axis CNC machined parts, as well as the precision components crafted by professional wire edm manufacturers, consistently meets requirements.

Through efficient management and continuous innovation in manufacturing technology, we consistently improve production efficiency and accuracy. This allows us to offer highly competitive pricing and exceptional service experiences while maintaining fast turnaround times and timely deliveries.

Material We Use

| Aluminum | Steel | Stainless steels | Copper | High Temperature Alloys |

| 6061, 6061-T6 | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36 | SUS201 | Brass: C27400, C28000, C36000 | Titanium Alloy TC4/Ti-6AI4V |

| 7075, 7075-T6 | Die steel: M238, S7. | 2205 | Bronze: Tin Bronze | Titanium Alloy TA1 |

| 2024 | Alloy steel | SUS303 | Beryllium copper | Titanium Alloy TA2 |

| 5052 | High-speed steel | SUS304 | Copper C101 (T2) | Magnesium Alloy AZ31B |

| 5083 | Cold rolled steel | SUS316 | Copper C103 (T1) | Magnesium Alloy AZ91 |

| 6063 | Bearing steel | SUS316L | Copper C103 (TU2) | Nickel |

| 6082 | Spring steel | SUS420 | Copper C110 (TU0) | |

| AL6013 | SUS430 | |||

| Fixture Aluminum | SUS431 | |||

| ADC12 (A380) | SUS440C | |||

SUS630/17-4PH/15-5PH | ||||

AISI304 | ||||

| 3Cr13, GCr15, |

Precision Machining Applications Industry

Widely used in industries such as aerospace, Automotive, Medical Equipment, New Energy, Robot& Surgical Robot, Semi-conductor, oil and gas, Food Processing, Mechanical equipment, Mining, Power Generation, and Transportation

Ideal for manufacturing components like turbine blades, propellers, and orthopedic implants.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文