-

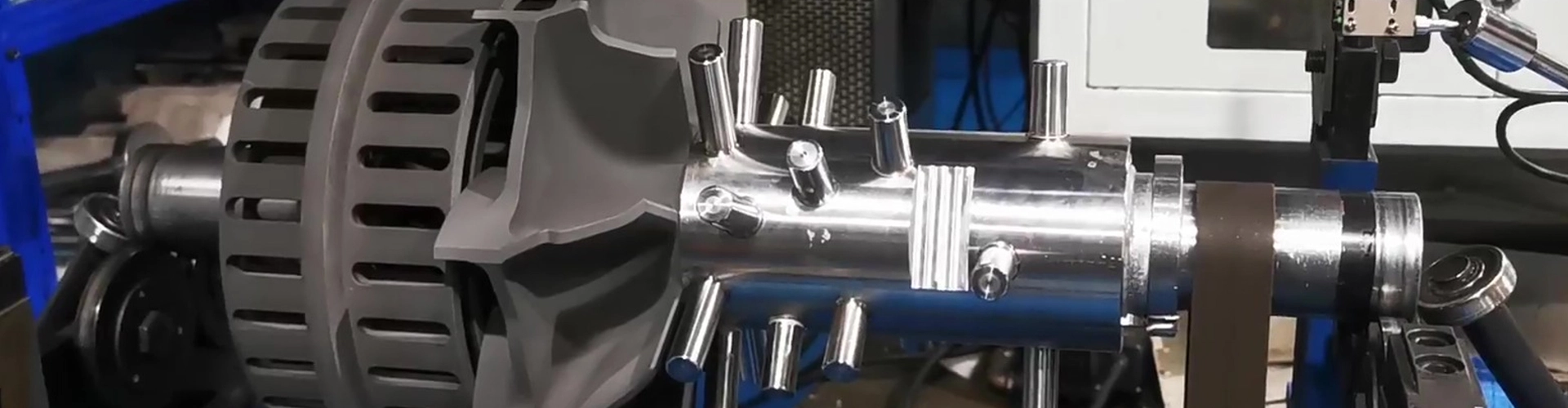

Precision Dynamic Balancing

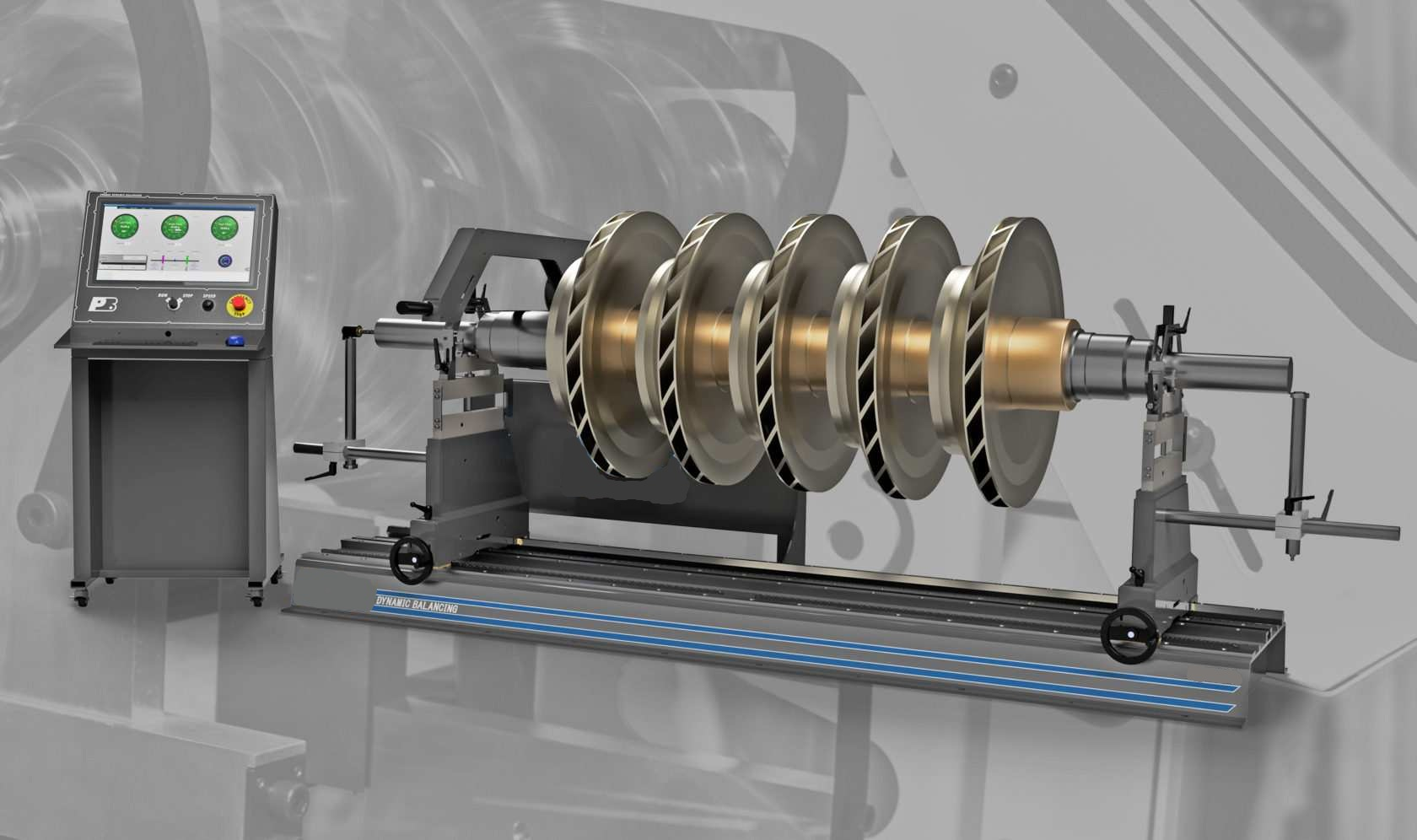

Zhihui Precision equipped with impeller dynamic balancing equipment at the forefront of the industry, integrating advanced algorithms and precision sensing technology to realize micron-level precision calibration. Dramatically reduce vibration and energy consumption, providing customers with reliable auto dynamic balancing solutions tailored to their industrial needs.

Dynamic Balancing Overview

Overview of Dynamic Balancing

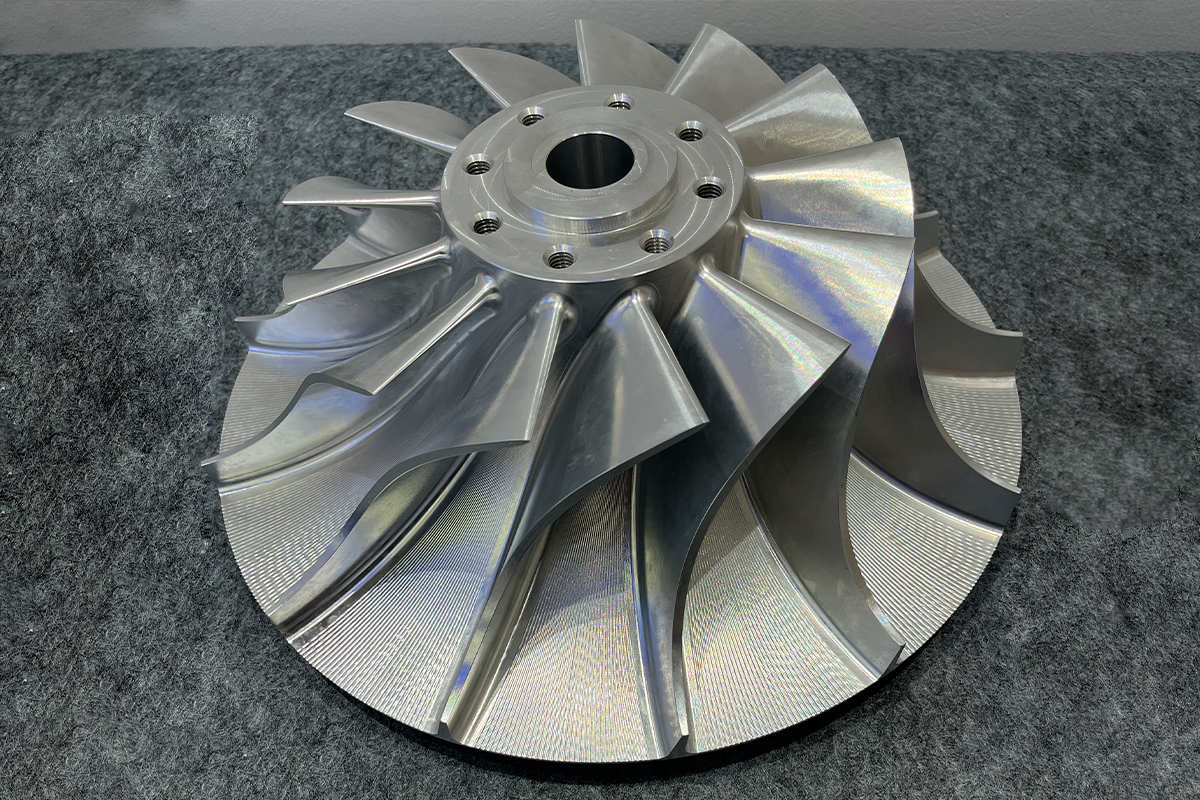

Dynamic Balancing is a technique used for rotating machinery to reduce or eliminate vibrations and centrifugal forces caused by uneven mass distribution. By adjusting the mass distribution of rotating components, dynamic balancing (particularly auto dynamic balancing) significantly improves the operational stability, lifespan, and safety of rotating equipment such as motors, turbines, fans, and rotors, with auto dynamic balancing offering streamlined precision for modern industrial needs.

Principle of Dynamic Balancing:

When the mass distribution of a rotating component is uneven, centrifugal forces are generated, leading to increased vibration, noise, and potential damage to bearings or other critical parts. Dynamic balancing eliminates these unbalanced forces by adding or removing mass at specific locations, ensuring that the center of gravity aligns with the rotational axis.

Steps of Dynamic Balancing:

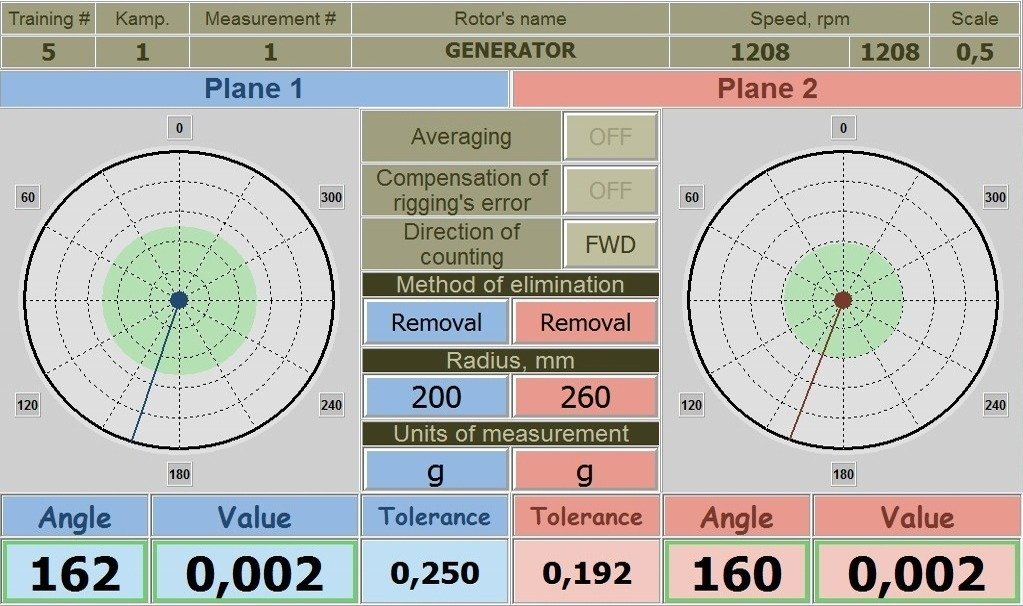

Detect Imbalance: Use a dynamic balancing machine or vibration analyzer to measure the amount and phase of imbalance in the rotating component.

Calculate Correction: Based on the measurement results, calculate the mass to be added or removed at specific locations.

Implement Correction: Achieve balance by adding counterweights (e.g., balance weights) or removing material (e.g., drilling).

Verify Results: Re-test the rotating component to ensure the imbalance is within acceptable limits.

Dynamic balancing is a critical process in the manufacturing and maintenance of rotating equipment, significantly enhancing performance and reliability.

Benefits of Dynamic Balancing

Advantages of Dynamic Balancing

Dynamic Balancing is a critical technology in the manufacturing and maintenance of rotating machinery. Its main advantages include:

1. Reduced Vibration

Dynamic balancing effectively reduces vibrations during equipment operation by adjusting the mass distribution of rotating components, enhancing operational smoothness and comfort.

2. Extended Equipment Lifespan

By minimizing vibrations, dynamic balancing reduces wear on bearings, shafts, and other mechanical parts, extending the equipment's service life.

3. Improved Operational Safety

Dynamic balancing lowers the risk of failures caused by vibrations, preventing equipment damage or unexpected downtime, and ensuring safe operation.

4. Enhanced Operational Efficiency

By eliminating unbalanced forces, dynamic balancing optimizes the efficiency of rotating equipment, reducing energy loss and operational costs.

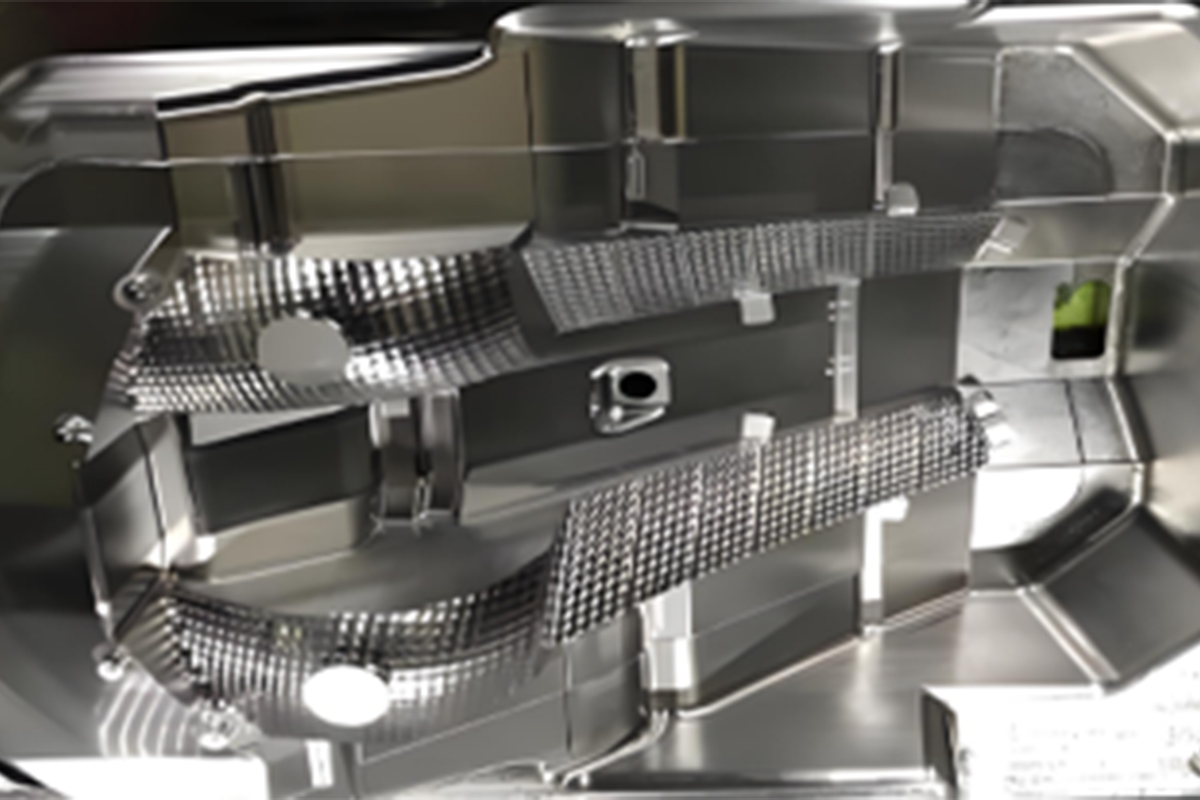

5. Improved Product Quality

For precision equipment or high-precision components, dynamic balancing ensures higher machining accuracy and product quality.

6. Reduced Noise

Dynamic balancing decreases noise caused by vibrations, improving the working environment.

7. Wide Applicability

Dynamic balancing is suitable for various rotating equipment, such as motors, turbines, fans, and crankshafts, with broad application across industries.

Dynamic balancing technology not only enhances equipment performance and reliability but also reduces operational costs, making it an indispensable process in modern manufacturing.

Applications of Dynamic Balancing

Dynamic Balancing technology is widely used in the manufacturing, maintenance, and optimization of various rotating equipment and machinery. Below are its main application fields:

1. Automotive Industry:

Engine Components: Such as crankshafts, camshafts, and flywheels.

Transmission Systems: Such as drive shafts, tires, and brake discs.

Motors and Fans: Such as cooling fans and air conditioning compressors.

2. Aerospace:

Turbine Engines: Such as turbine blades and rotors.

Propellers and Rotors: Such as helicopter rotors and aircraft propellers.

Auxiliary Equipment: Such as aviation motors and pumps.

3. Power Industry:

Generators and Motors: Such as large generator rotors and wind turbine blades.

Turbines: Such as steam turbines and gas turbines.

4. Manufacturing:

Industrial Machinery: Such as pumps, compressors, and centrifuges.

Machine Tools: Such as spindles and grinding wheels.

Household Appliances: Such as washing machine drums and vacuum cleaner motors.

5. Medical Equipment:

Precision Instruments: Such as centrifuges and medical motors.

Surgical Tools: Such as high-speed drills and orthopedic devices.

6. Energy Industry:

Wind Power: Such as wind turbine rotors.

Hydropower: Such as hydro turbine blades.

Dynamic balancing technology plays a critical role in various industries, significantly enhancing the performance, reliability, and safety of rotating equipment.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文