-

Introduction to the basic Situation of Die Casting

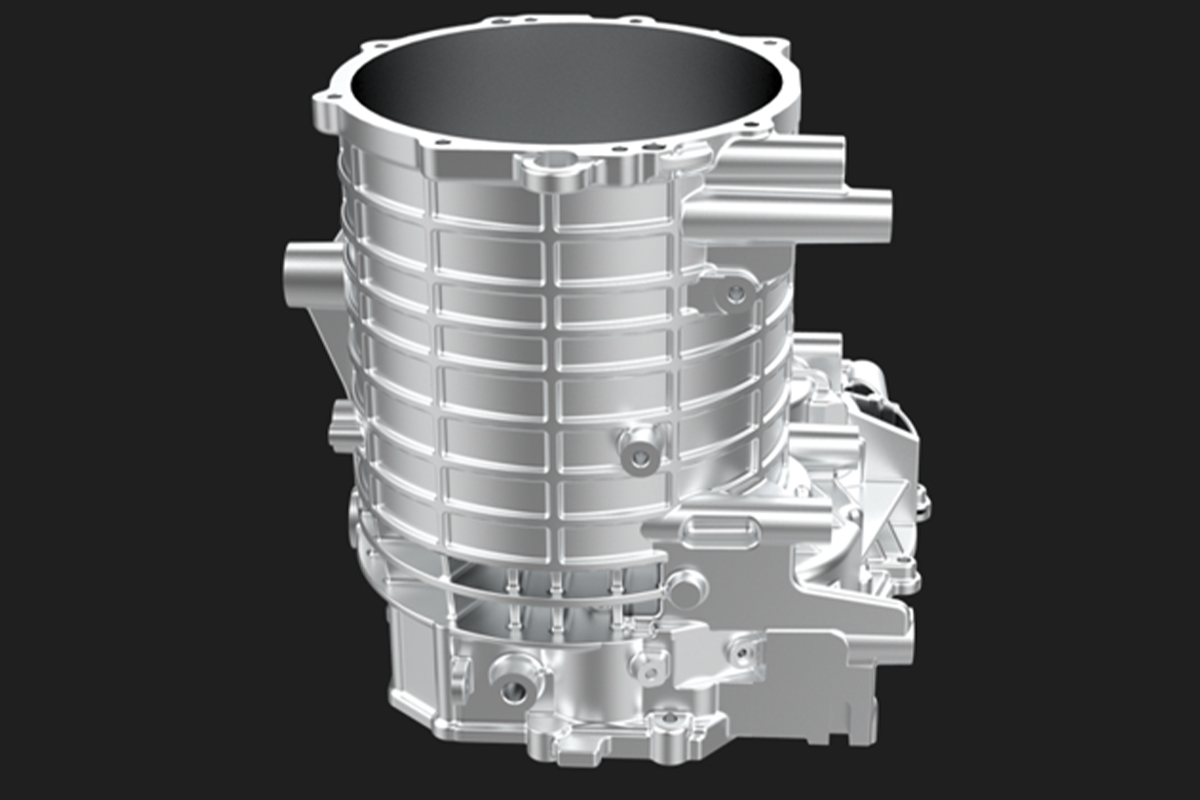

Zhihui Precision can provide customized metal die casting services for both small and large batch production, ensuring on-time and fast delivery.

Our metal die casting materials include aluminum, magnesium, zinc, and steel.

Metal die casting offers several advantages, such as low per-unit costs in high-volume production, exceptional surface finish, and dimensional stability. It enables the creation of complex geometries with minimal or no post-processing, making it an ideal choice for medium to large-sized parts that would otherwise require slower and more costly manufacturing methods, with cnc die casting enhancing precision and efficiency.

With years of seamless collaboration with our metal die casting partners, we deliver a range of high-quality metal die casting services, ensuring your products are brought to life with precision and perfection through this advanced manufacturing process.

Die Casting Overview

Metal die casting is a highly efficient and precise manufacturing method, primarily used to produce metal parts with complex shapes. Below are the key characteristics of the metal die casting process, including those unique to cnc die casting:

High Production Efficiency:

The die casting process injects molten metal into molds at high speed and pressure, enabling the production of large quantities of parts in a short time, making it ideal for mass manufacturing.

High Precision and Complex Shapes:

Die casting can produce parts with intricate geometries and fine details, offering high dimensional accuracy and excellent surface finish, which reduces the need for additional machining.

Material Versatility:

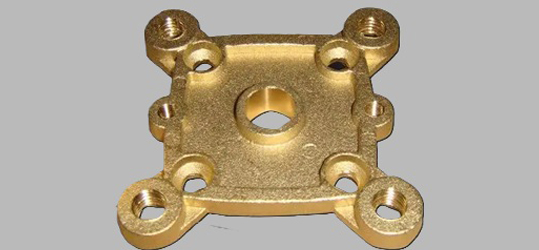

The process is suitable for a variety of metal materials, such as aluminum alloys, zinc alloys, magnesium alloys, and copper alloys, meeting diverse performance requirements.

High Strength and Lightweight Design:

Die-cast parts typically exhibit high strength and rigidity. The use of lightweight alloys (e.g., aluminum and magnesium) also enables lightweight design solutions.

Superior Surface Quality:

Die-cast parts have smooth surfaces that can be directly subjected to surface treatments like plating or painting, enhancing both appearance and functionality.

Long Mold Lifespan:

Die casting molds are usually made of high-strength steel, capable of withstanding high temperatures and pressures, resulting in a long service life suitable for high-volume production.

Cost-Effectiveness:

Although mold manufacturing costs are relatively high, the per-unit cost decreases significantly in large-scale production, offering strong economic benefits.

Design Flexibility:

The process supports complex internal structures and thin-walled designs, allowing the integration of functional features such as threads, holes, and reinforcement ribs.

Rapid Cooling and Solidification:

Molten metal cools and solidifies quickly within the mold, forming a dense microstructure that enhances the mechanical properties of the parts.

Eco-Friendliness and Sustainability:

Die casting generates minimal waste, and any metal scrap can be recycled and reused, aligning with environmental sustainability goals.

In summary, metal die casting is widely used in industries such as automotive, electronics, home appliances, and aerospace due to its high efficiency, precision, material versatility, and design flexibility. It is an indispensable process in modern manufacturing.

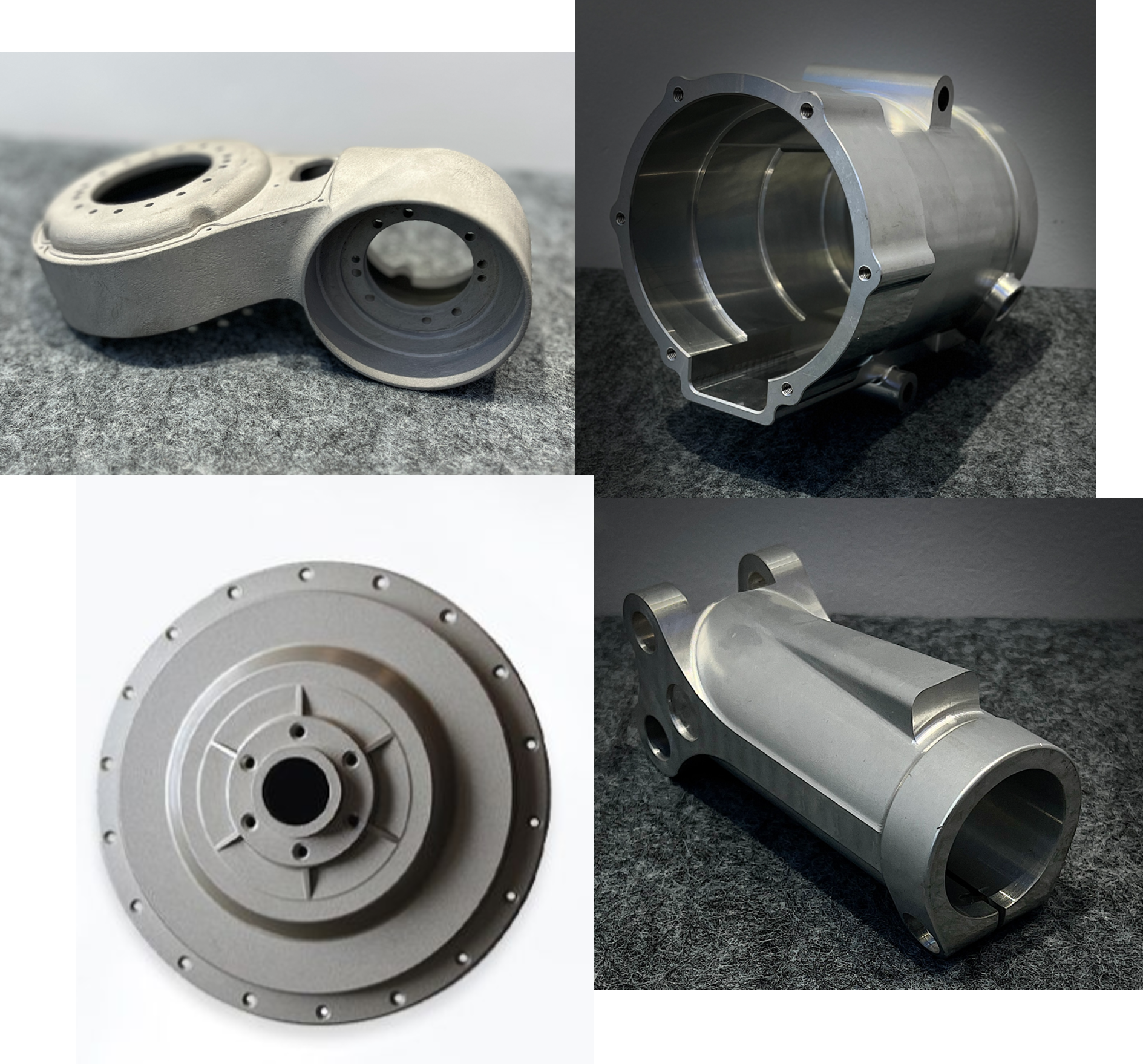

Die Casting Materials

Our primary materials include aluminum, zinc, magnesium, and copper, each offering distinct properties and advantages in die casting applications.

Aluminum die casting is ideal for industries that prioritize lightweight, high-strength components. The process excels in scalability, precision, and material efficiency, making it a cornerstone of modern manufacturing.

Zinc die casting excels in applications requiring intricate details, tight tolerances, superior surface finish, and compatibility with decorative finishes, making it a preferred choice for consumer electronics, automotive, and hardware industries.

Magnesium die casting is unmatched for applications demanding extreme lightweighting, high strength, and precision. its use in automotive, aerospace, and electronics

Copper die casting is a niche but critical process for industries requiring unmatched conductivity and thermal management, it excels in high-performance electrical, automotive, and industrial applications.

Types of Die Casting Processes

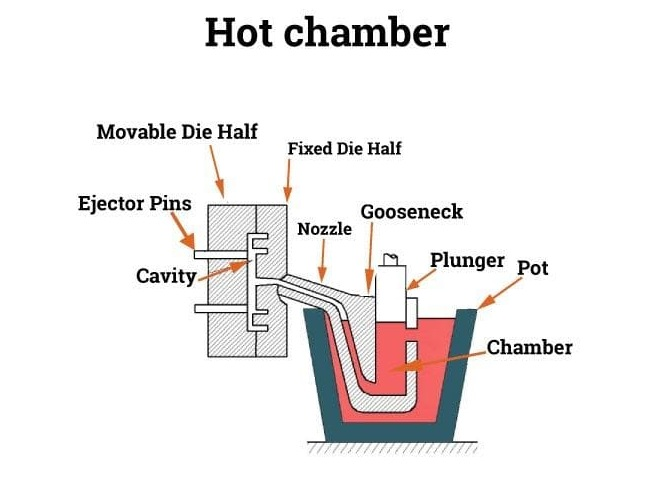

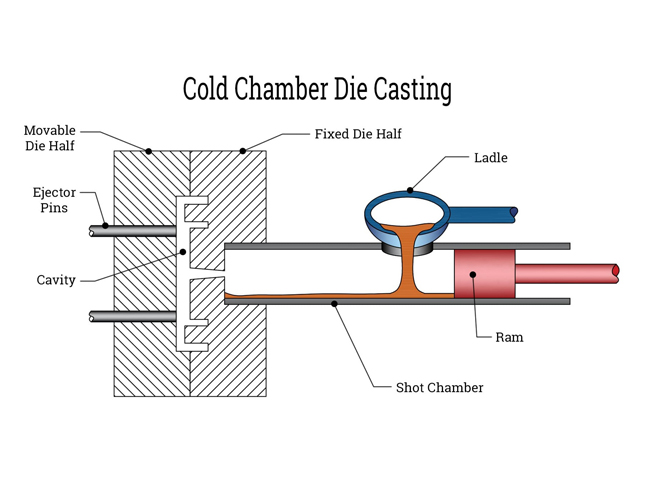

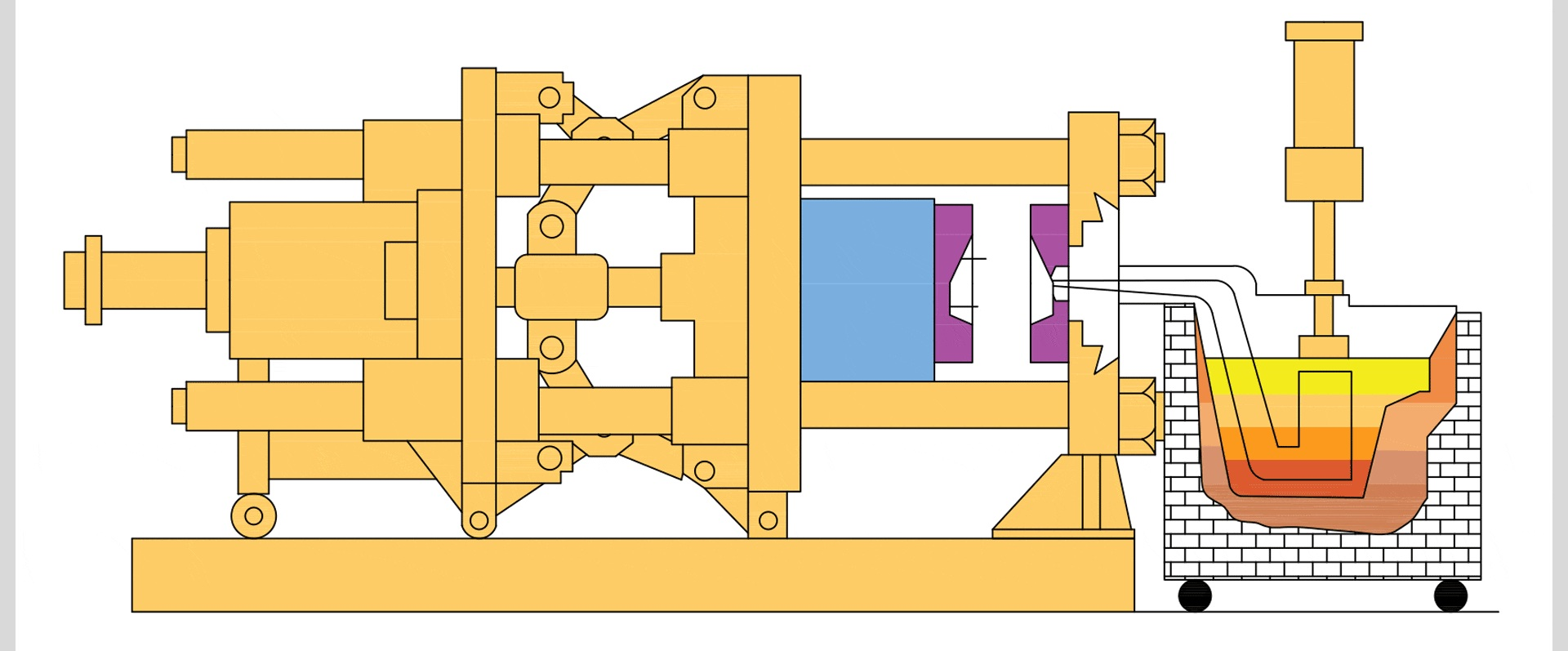

Die casting methods generally involve injecting molten metal into a mold under high pressure to ensure complete coverage of the mold's contours. We utilize both Hot Chamber and Cold Chamber Die Casting methods to suit different material requirements and project specifications.

Hot chamber die casting is the gold standard for high-volume, low-melting-point alloy production, offering unmatched speed, efficiency, and surface quality. While restricted to metals like zinc and magnesium, its cost-effectiveness and rapid cycle times make it indispensable for the automotive, electronics, and consumer goods industries. Advances in die materials and process automation continue to expand their capabilities, ensuring their relevance in precision manufacturing.

Cold chamber die casting is essential for producing high-strength, heat-resistant components from aluminum, copper, and other challenging alloys. While slower and costlier than hot chamber processes, its ability to handle extreme temperatures and deliver dense, durable parts makes it indispensable in automotive, aerospace, and industrial sectors. Advances in vacuum-assisted casting and die coatings continue to refine their efficiency, ensuring their role in precision manufacturing for critical applications.

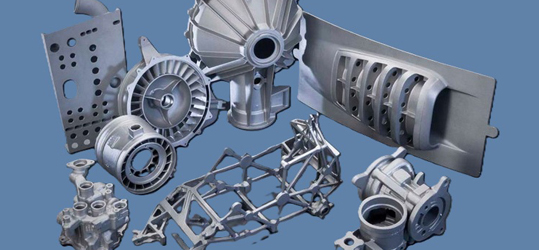

Applications of Die Casting

Die casting is a versatile manufacturing process used across industries to produce lightweight, durable, and complex metal parts with high precision. Below is a breakdown of its key applications by sector:

1. Automotive Industry

2. Electronics & Consumer Goods

3. Aerospace & Defense

4. Industrial Machinery

5. Medical Devices

6. Energy & Renewable Sector

7. Telecommunications

8. Decorative & Architectural

Die casting remains a cornerstone of modern manufacturing, enabling innovation in industries from automotive to healthcare. Its adaptability to new alloys and technologies ensures continued relevance in an era demanding efficiency, sustainability, and precision.

Advantages of Die Casting

Key Advantages Driving These Applications

Precision & Complexity: Achieve intricate shapes with minimal machining.

Material Efficiency: Near-net-shape production reduces waste.

Scalability: Cost-effective for high-volume runs (e.g., automotive/electronics).

Sustainability: Recyclable materials (e.g., aluminum, zinc) align with circular economy goals.

Performance: Combines lightweighting with strength, conductivity, and corrosion resistance.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文