-

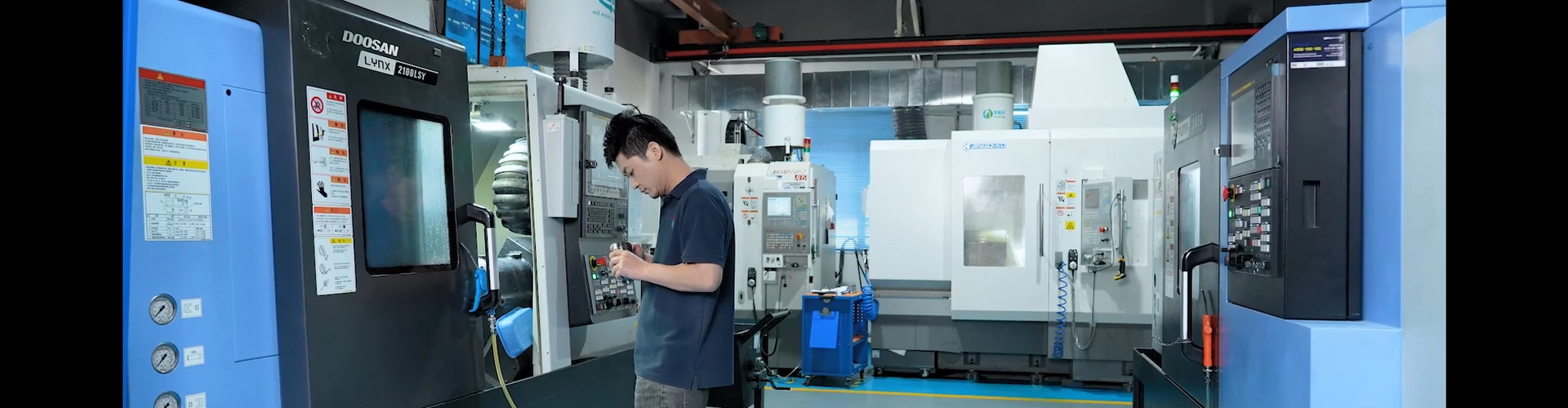

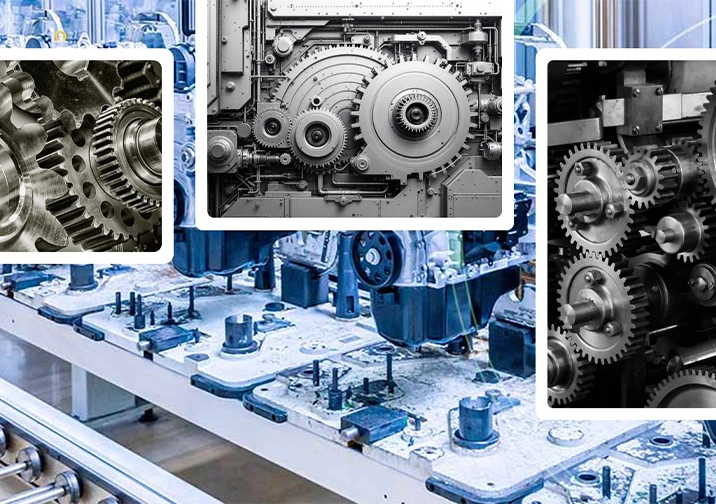

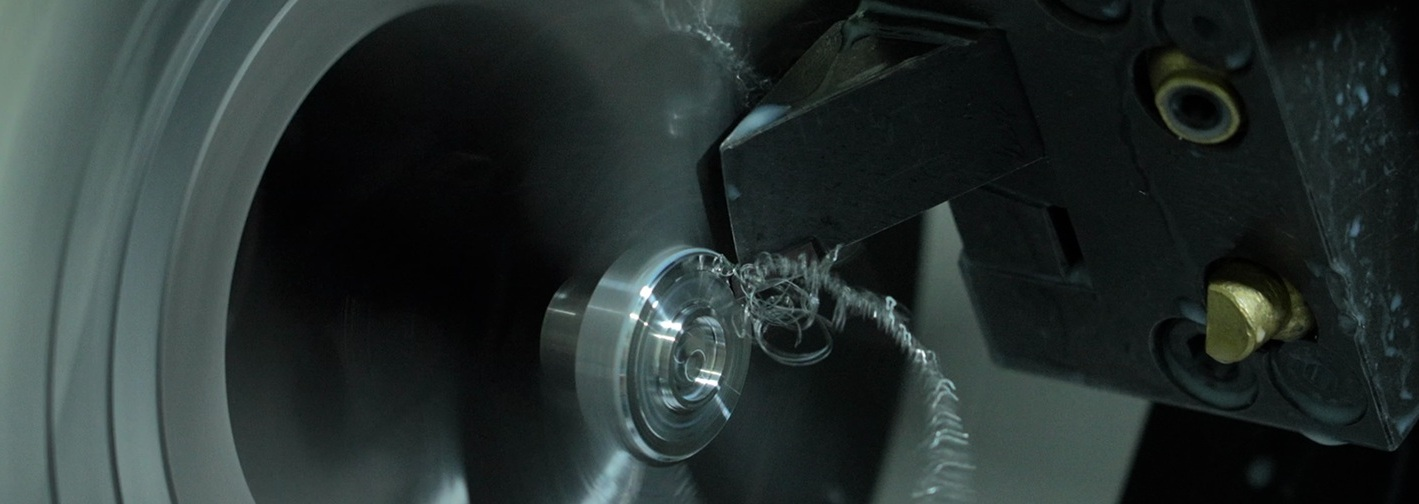

Precision CNC Turning-Milling Machining

Zhihui Precision for better align with and meet customer demands, Zhihui Precision has equipped itself with high-precision turn-mill machining centers, including both vertical and horizontal turn-mill centers. This comprehensive setup enables us to better serve our clients as a trusted cnc turned components manufacturer, delivering professional cnc turning and milling services and manufacturing a wide array of complex products.

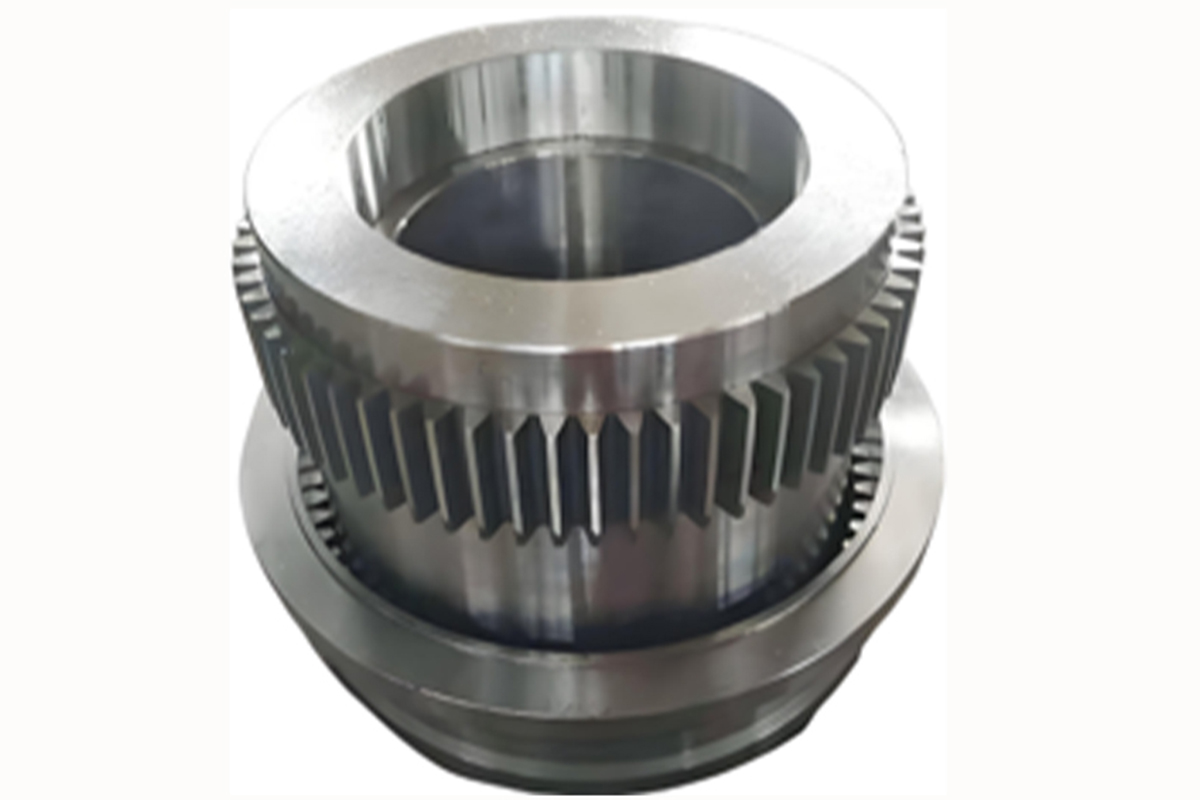

Providing precision CNC Turning-Milling machining with a tolerance of 0.001mm;

Custom manufacturing of metal parts from prototyping to mass production

Prototype design within 3-5 days and mass production within 1-2 weeks

CNC Turning-Milling machining and forming of precision metal parts

Zhihui Precision is ISO 9001 Certified Factory, Aerospace AS9100 and Medical 13485 certifications in progress;

±0.001mm and above precision requirements can be processed

Precision CNC Turning-Milling Machining Overview

Horizontal & Vertical turning centers:

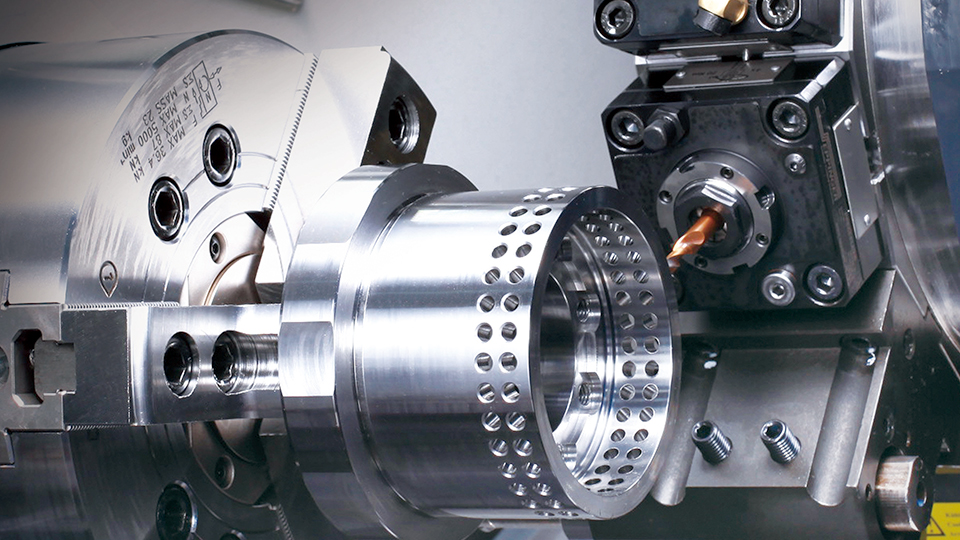

The difference between lathes and turning centers, for the most part, lathes today are commonly referred to as CNC lathes, and CNC turning centers. The CNC lathe is a simpler 2-axis (X and Z-axis) machine that is computer-controlled and generally has one spindle. They are commonly flat-bed type and may have only a minimal protective enclosure around the machine and the machine ways. CNC turning centers are also computer-controlled but are more powerful and can have 3, 4, or 5 axes with more versatile capabilities and applications such as turning, drilling, tapping, and milling using live tools with a powered rotary tool turret, sub-spindle (dual spindles), Y-axis, and multiple turrets—making them ideal for delivering precision cnc turning and milling services. They are usually slant-bed type and have full machine enclosures to keep chips and coolant splashes within the machine. CNC turning centers have higher production capabilities than CNC lathes, supporting efficient cnc milling and turning services for diverse industrial needs.

As a professional cnc turned components manufacturer, these machines are utilized across several industries such as automotive, aerospace, designed for long term accuracy, and heavy engineering. Capable of producing complex parts, the machines handle materials like steel, aluminum, and plastics. It is widely used in the heavy cutting of brake drums, brake discs and wheel hubs of medium and heavy automobiles, as well as in the related industries which need to cut large-diameter discs strongly.

Benefits of Precision CNC Turning-Milling Machining

Advantages of Precision CNC Turn-Mill Machining Centers:

Precision CNC turn-mill machining centers combine the functions of turning and milling, enabling the multi-faceted machining of complex parts in a single setup, significantly improving machining efficiency and accuracy. These machining centers are divided into vertical and horizontal types, each with its unique advantages that enhance the versatility of cnc milling and turning services.

Advantages of Vertical Turn-Mill CNC Machining Centers:

Space-saving: The vertical design occupies a small footprint, suitable for work environments with limited space.

Gravity-assisted: The vertical structure facilitates the natural fall of chips, reducing interference with the machining process.

Ease of operation: Operators can more easily observe and adjust the machining process.

Advantages of Horizontal Turn-Mill CNC Machining Centers:

Stability: The horizontal design offers better stability and rigidity, suitable for heavy cutting and large workpiece machining.

Multi-faceted machining: Horizontal machines are often equipped with rotary tables, enabling multi-faceted machining of workpieces and increasing production efficiency.

Chip management: Chips from horizontal machines are easier to remove, helping to maintain a clean work area and extend tool life.

Advantages of Vertical Turn-Mill CNC Machining Centers:

Space-saving: The vertical design occupies a small footprint, suitable for work environments with limited space.

Gravity-assisted: The vertical structure facilitates the natural fall of chips, reducing interference with the machining process.

Ease of operation: Operators can more easily observe and adjust the machining process.

Why Choose Zhihui Precision CNC Machining Services

We operate over 50 CNC machining centers, including more than 40 five-axis CNC machining centers, providing ample production capacity to handle batch orders simultaneously and ensuring short lead times for customer projects.

Our five-axis machining centers are designed with optimal and high-performance structures, achieving machining accuracy of +/- 0.002mm.

We employ experienced project managers with fluent English communication skills, enabling effective collaboration with customers and ensuring the quality and delivery timelines of their projects are meticulously managed.

Our adoption of the MES digital management system guarantees effective control over every production process.

We strictly adhere to a quality control system that oversees every stage of preparation, manufacturing, and inspection, ensuring that the quality of our five-axis CNC machined parts consistently meets requirements.

Through efficient management and continuous innovation in manufacturing technology, we consistently improve production efficiency and accuracy. This allows us to offer highly competitive pricing and exceptional service experiences while maintaining fast turnaround times and timely deliveries.

Material We Use

| Aluminum | Steel | Stainless steels | Copper | High Temperature Alloys | Plastic |

| 6061, 6061-T6 | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36 | SUS201 | Brass: C27400, C28000, C36000 | Titanium Alloy TC4/Ti-6AI4V | PEEK |

| 7075, 7075-T6 | Die steel: M238, S7. | 2205 | Bronze: Tin Bronze | Titanium Alloy TA1 | PEI |

| 2024 | Alloy steel | SUS303 | Beryllium copper | Titanium Alloy TA2 | PAI |

| 5052 | High-speed steel | SUS304 | Copper C101 (T2) | Magnesium Alloy AZ31B | PPS |

| 5083 | Cold rolled steel | SUS316 | Copper C103 (T1) | Magnesium Alloy AZ91 | PTFE(Teflon) |

| 6063 | Bearing steel | SUS316L | Copper C103 (TU2) | Nickel | PA(Nylon) |

| 6082 | Spring steel | SUS420 | Copper C110 (TU0) | PPA | |

| AL6013 | SUS430 | POM | |||

| Fixture Aluminum | SUS431 | PMMA | |||

| ADC12 (A380) | SUS440C | PBT | |||

SUS630/17-4PH/15-5PH | ABS | ||||

AISI304 | PC | ||||

| 3Cr13, GCr15, | PC/ABS |

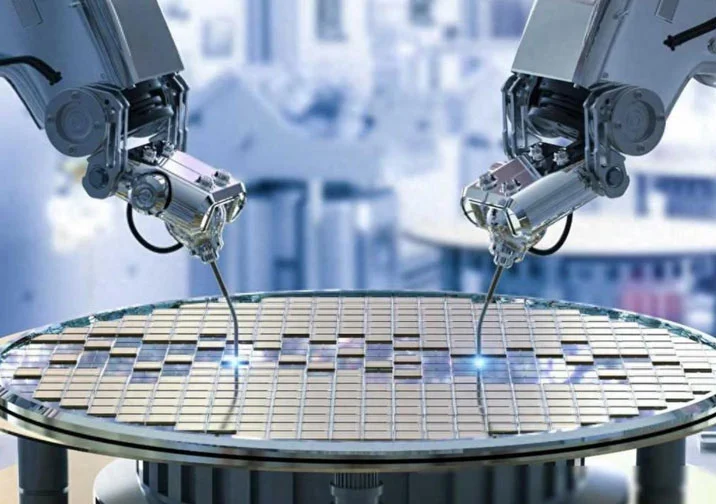

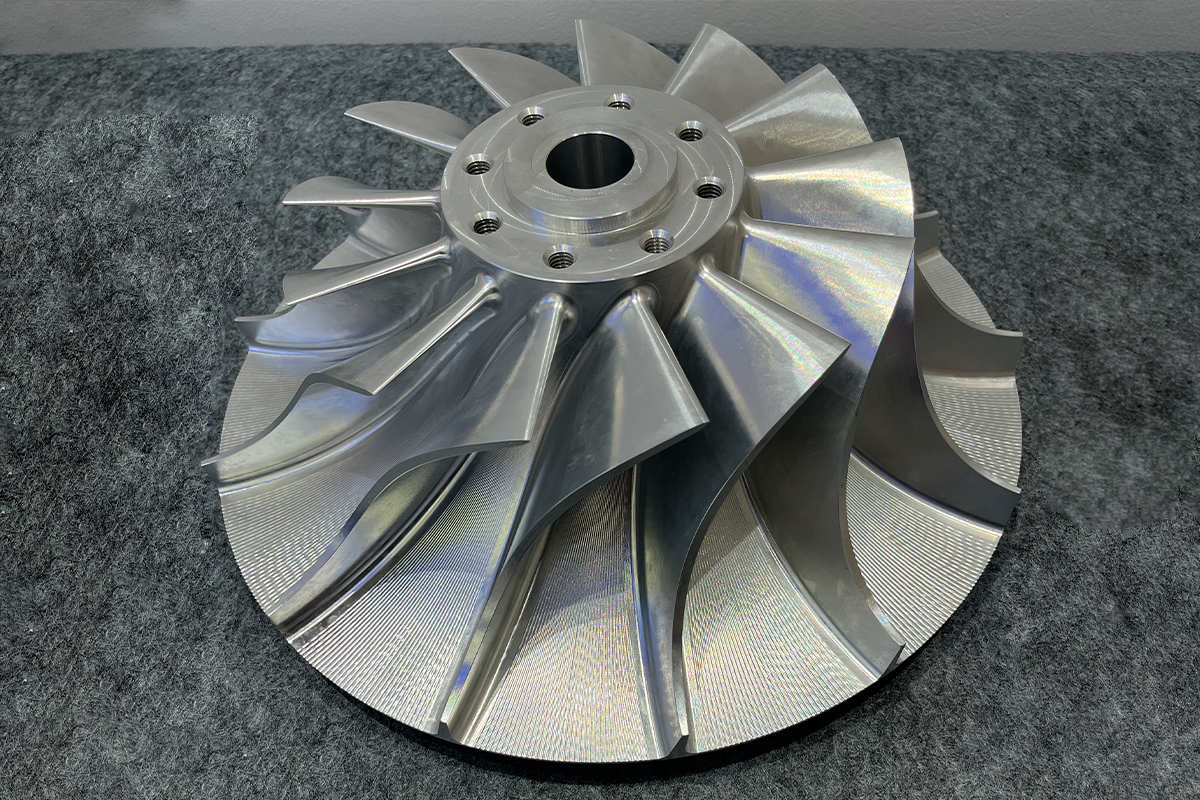

Precision Machining Applications Industry

Widely used in industries such as aerospace, Automotive, Medical Equipment, New Energy, Robot& Surgical Robot, Semi-conductor, oil and gas, Food Processing, Mechanical equipment, Mining, Power Generation, and Transportation.

Ideal for manufacturing components like turbine blades, propellers, and orthopedic implants.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文