-

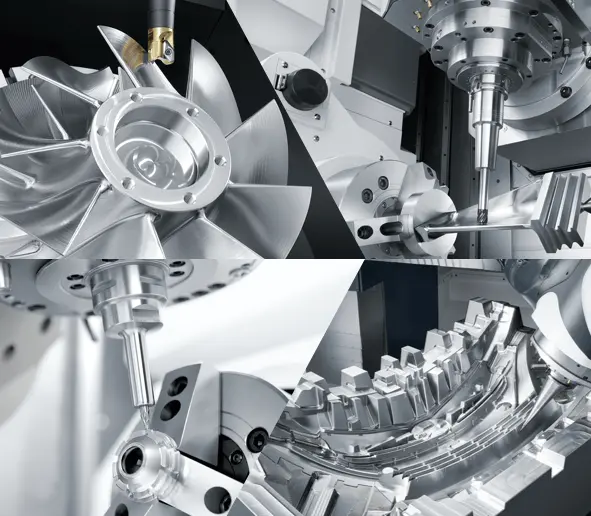

Precision 5 Axis CNC Machining Manufacturing Factory

Zhihui Precision is the largest 5-axis CNC machining company in southern China, renowned for its state-of-the-art facilities and expertise in 5 axis cnc service and 5 axis machining services. With over 50+ CNC machining centers and more than 40 multi-axis 5-axis CNC machining centers, the company is committed to delivering top-quality services to various industries. As a trusted provider of 5-axis CNC machining services, Zhihui Precision specializes in high-precision manufacturing, offering a tolerance of 0.001mm for complex designs and customized components. Whether you require advanced 5-axis CNC machining solutions or access to cutting-edge technology, Zhihui Precision ensures accuracy, reliability, and efficiency in every 5 axis cnc machining services and 5 axis manufacturing project.

Custom manufacturing of metal parts from prototyping to mass production

Prototype design within 3-5 days and mass production within 1-2 weeks

5 Axis CNC machining and forming of precision metal parts

ISO 9001 Certified Factory, Aerospace AS9100 and Medical 13485 certifications in progress;

Tolerance with±0.001mm and above precision requirements can be processed

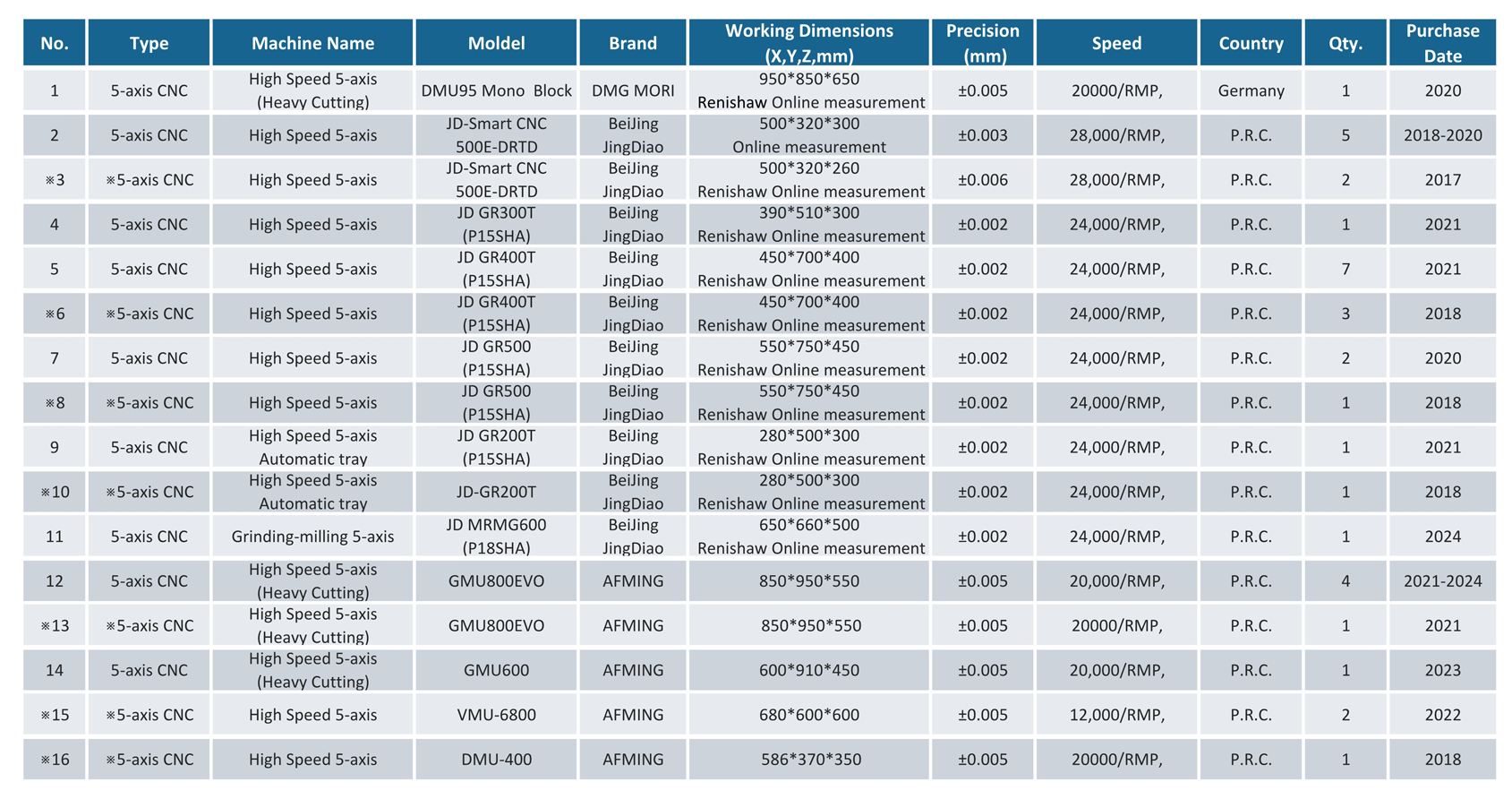

5-Axis CNC Machinery List

Precision 5 Axis CNC Machining Service

No matter you need 1 piece or a large batch, Zhihui Precision always keeps the same service and works carefully on your project and parts. So if you have any parts that need CNC machining & precision cutting services, you are always welcome and can provide high-quality, on-demand rapid manufacturing services for custom parts prototyping and product manufacturing, including professional 5 axis cnc machining services and reliable 5 axis manufacturing solutions.

Advantage

Zhihui Precision has a large number of high-precision five-axis machining equipment (over 50+ CNC machining centers and over 40 multi-axis 5-axis CNC machining centers), mature technology and management team can ensure that the production of a high rate of correctness, the production management of MES system to effectively monitor the production of each production link to ensure that the production of timely delivery—all of which solidifies our position as a reliable 5 axis machining manufacturer and enables us to stand out in market competition through high-quality 5 axis cnc service.

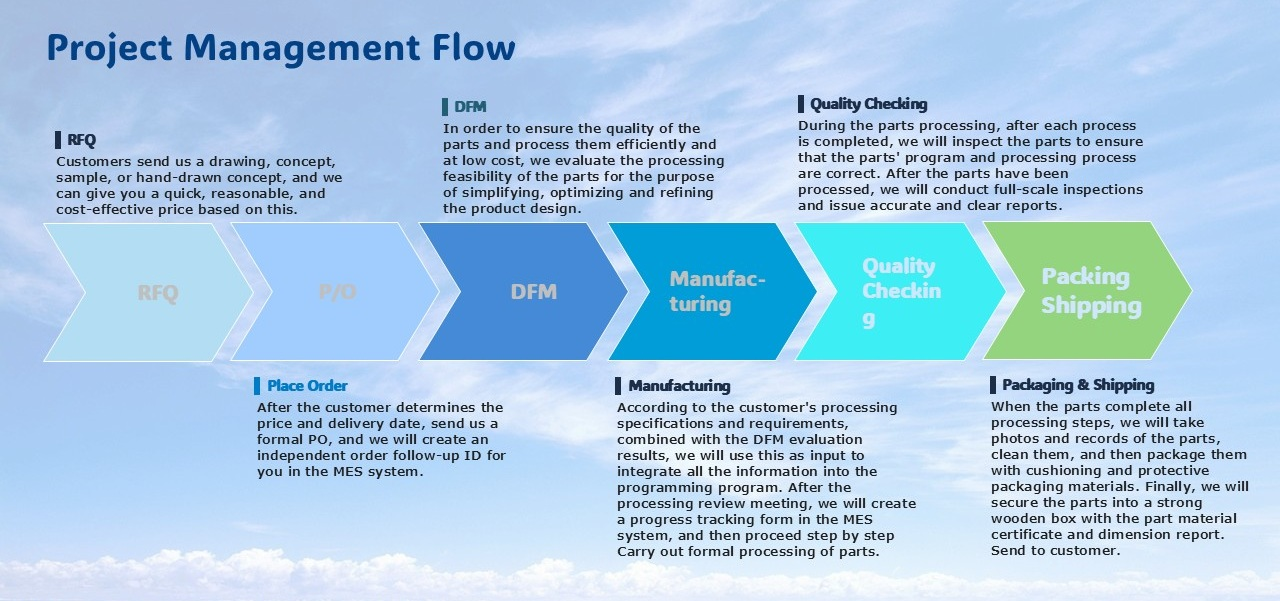

Project Management

For every customer requiring 5 axis machining services, we assign a dedicated project manager to take care of everything carefully, and working closely with the customer and our sales team, this can make customer very easy to follow the project situation and easy to contact a familiar person. This makes working easy and getting the right answer easily.

Quality Management

As a dedicated 5 axis machining manufacturer, we are equipped with comprehensive testing equipment and a proficient quality management team and processes. We consistently uphold the principle that quality is paramount, continuously providing our customers with reliable quality and excellent service, every time we ship the parts to customers, always with but not limited:

First sample inspection report

Full sample inspection report

Material certification sheet

Part dimension inspection drawing

Delivery note

Surface treatment report

Certifications

As a distinguished manufacturer specializing in 5-axis CNC machining, we possess and offer our clients a range of relevant certifications, including but not limited to:

ISO 9001:2015

Aerospace Industry AS9100(being obtained)

Medical 13485(being negotiation)

RoHS

CE

Our 5 Axis CNC Machining Experience

Precision 5 Axis CNC Machining Services & Manufacturing

If you are seeking a reliable 5-axis CNC machining manufacturer, Zhihui Precision is your best choice. Not only can we accommodate production needs ranging from small batches to large-scale manufacturing, but we also specialize in machining components of various sizes and shapes. As we have the largest number of 5-axis machines in South China, our highly trained and experienced team, combined with robust management systems and stringent quality control, ensures that we can meet customer requirements with precision and deliver an exceptional service experience.

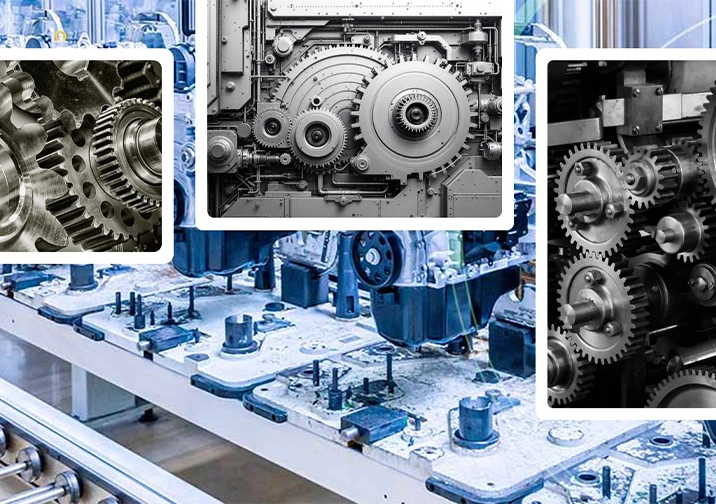

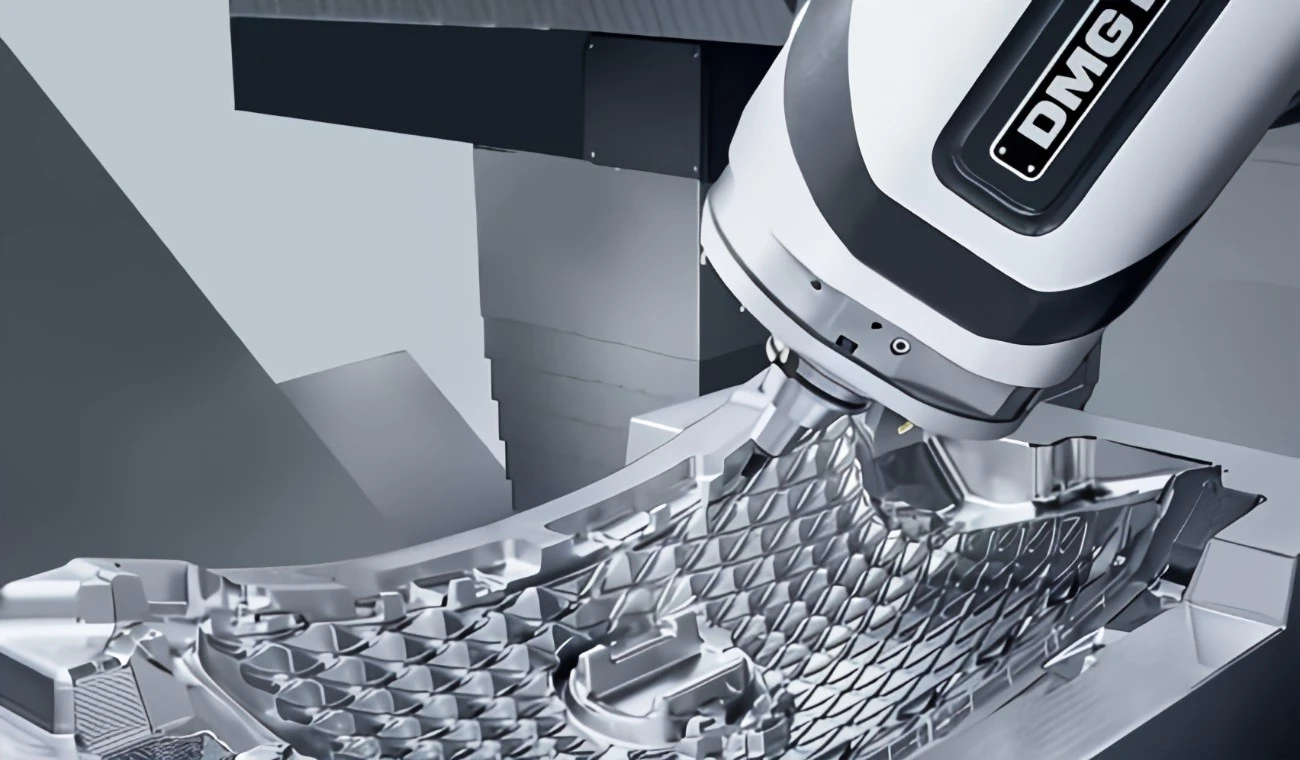

To meet the diversified production needs and overcome all kinds of processing problems, the company has spared no effort in the introduction of equipment. Now we have purchased 5-axis machining centers 40 units and brands are Germany DMG MORI five-axis machining centers, Beijing Jingdiao, the US Haas, Korea Doosan and Afming, these devices have high precision, high stability advantages, can efficiently process difficult, complex products, from precision parts of the fine sculpture, to the perfect shape of complex surfaces, can easily handle, with excellent hardware strength for product quality and production efficiency. These machines are capable of efficiently machining difficult and complex products, from fine carving of precision parts to perfect shaping of complex surfaces, providing a solid guarantee for product quality and production efficiency with their excellent hardware strength.

What is 5 Axis Machining?

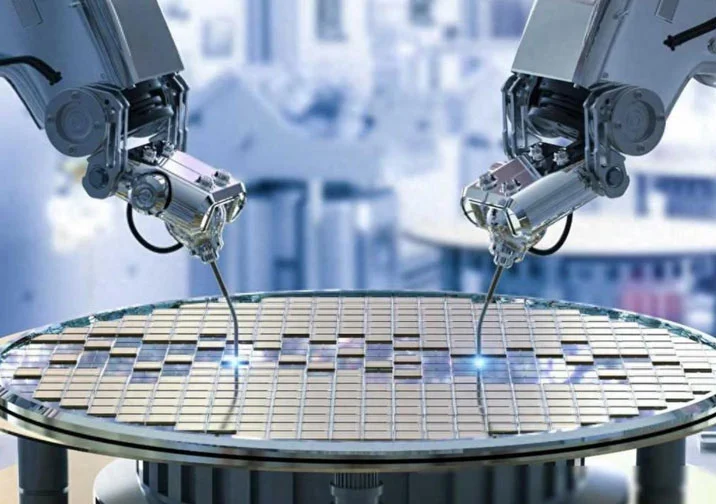

About Precision five-axis CNC machining which represents a paradigm shift in modern manufacturing, offering transformative benefits that extend far beyond traditional machining capabilities. Its unique ability to manipulate workpieces along five axes simultaneously unlocks new dimensions of design freedom, enabling the production of highly intricate and organic shapes that were previously unachievable. This technological leap is particularly impactful in industries where innovation and precision are paramount, such as advanced robotics, renewable energy systems, and next-generation consumer electronics.

One of the most profound advantages of five-axis CNC machining is its role in fostering sustainable manufacturing practices. By minimizing material waste through precise, single-setup machining, it significantly reduces the environmental footprint of production processes. Additionally, its ability to optimize tool paths and cutting strategies leads to lower energy consumption, aligning with global efforts to create greener industrial ecosystems.

The technology also acts as a catalyst for the integration of advanced materials into industrial applications. From high-strength alloys to engineered composites, five-axis CNC machining enables the efficient processing of materials that are critical for cutting-edge innovations but traditionally difficult to work with. This capability is driving breakthroughs in fields like electric vehicle manufacturing, where lightweight and durable components are essential for performance and efficiency.

Furthermore, five-axis CNC machining is reshaping the relationship between design and production. By bridging the gap between complex digital models and physical reality, it empowers engineers to experiment with bold, unconventional designs without being constrained by manufacturing limitations. This synergy between creativity and technical feasibility is accelerating the development of products that are not only functional but also aesthetically groundbreaking.

In essence, precision five-axis CNC machining is more than just an advanced manufacturing tool—it is a cornerstone of industrial evolution. By enabling unprecedented levels of precision, efficiency, and innovation, it is helping to redefine the boundaries of what is possible in modern manufacturing, paving the way for a future where complexity and sustainability coexist seamlessly.

Benefits of Precision 5 Axis Machining

High-precision and complex part machining, reducing setups and improving accuracy

Completing complex geometric shapes in a single operation, where traditional machining might struggle

Enhancing part accuracy, improving precision, and quality when producing parts with intricate features

Reducing part handling, setup times, and the number of machines required, saving time and enhancing machining accuracy

Minimizing material waste and extending spindle uptime through continuous and efficient operations

Producing parts on demand

Reducing costly workpiece fixtures and tooling redundancy

Decreasing the need for ancillary equipment, such as gauges and tools

Conducive to unattended operations—single-point loading and unloading

Improving traceability and documentation—done-in-one

Comprehensive support—hobbing, gear cutting, and skiving

Design for manufacturability

Full Range of Categories / Advanced Cutting Tool Management

Zhihui Precision implemented professional tool management and assigned dedicated personnel for tool installation to ensure precise operations. Additionally, we spares no expense in procuring high-precision tool heads, tool holders, and cutting tools, including high-precision thermal shrink tool holders, to comprehensively guarantee the effectiveness of tool usage. Leveraging a fully functional and high-performance digital management system, we have established a refined and intelligent management framework. This ensures that every aspect of the operation is closely coordinated under the guidance of digitalization, transforming the concept of effective digital management into reality.

Why Choose Zhihui Precision 5 Axis CNC Machining Services

We operate over 50 CNC machining centers, including more than 40 five-axis CNC machining centers, providing ample production capacity to handle batch orders simultaneously and ensuring short lead times for customer projects.

Our five-axis machining centers are designed with optimal and high-performance structures, achieving machining accuracy of +/- 0.002mm.

We employ experienced project managers with fluent English communication skills, enabling effective collaboration with customers and ensuring the quality and delivery timelines of their projects are meticulously managed.

Our adoption of the MES digital management system guarantees effective control over every production process.

We strictly adhere to a quality control system that oversees every stage of preparation, manufacturing, and inspection, ensuring that the quality of our five-axis CNC machined parts consistently meets requirements.

Through efficient management and continuous innovation in manufacturing technology, we consistently improve production efficiency and accuracy. This allows us to offer highly competitive pricing and exceptional service experiences while maintaining fast turnaround times and timely deliveries.

Material We Use

| Aluminum | Steel | Stainless steels | Copper | High Temperature Alloys | Plastic |

| 6061, 6061-T6 | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36 | SUS201 | Brass: C27400, C28000, C36000 | Titanium Alloy TC4/Ti-6AI4V | PEEK |

| 7075, 7075-T6 | Die steel: M238, S7. | 2205 | Bronze: Tin Bronze | Titanium Alloy TA1 | PEI |

| 2024 | Alloy steel | SUS303 | Beryllium copper | Titanium Alloy TA2 | PAI |

| 5052 | High-speed steel | SUS304 | Copper C101 (T2) | Magnesium Alloy AZ31B | PPS |

| 5083 | Cold rolled steel | SUS316 | Copper C103 (T1) | Magnesium Alloy AZ91 | PTFE(Teflon) |

| 6063 | Bearing steel | SUS316L | Copper C103 (TU2) | Nickel | PA(Nylon) |

| 6082 | Spring steel | SUS420 | Copper C110 (TU0) | PPA | |

| AL6013 | SUS430 | POM | |||

| Fixture Aluminum | SUS431 | PMMA | |||

| ADC12 (A380) | SUS440C | PBT | |||

SUS630/17-4PH/15-5PH | ABS | ||||

AISI304 | PC | ||||

| 3Cr13, GCr15, | PC/ABS |

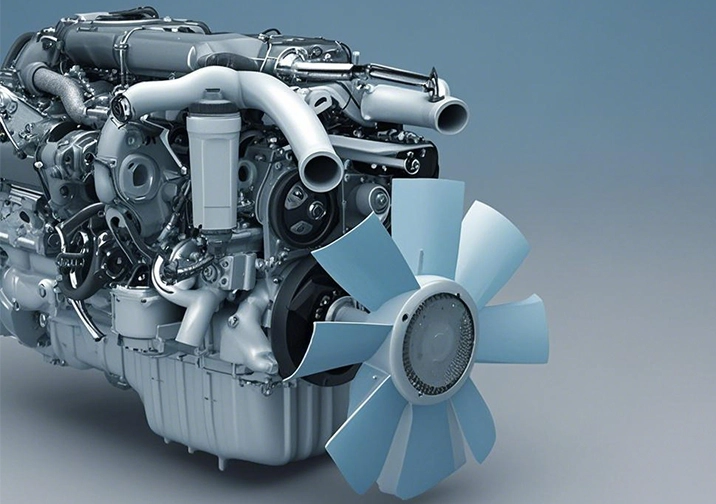

Precision Machining Applications Industry

Widely used in industries such as aerospace, Automotive, Medical Equipment, New Energy, Robot& Surgical Robot, Semi-conductor, oil and gas, Food Processing, Mechanical equipment, Mining, Power Generation, and Transportation

Ideal for manufacturing components like turbine blades, propellers, and orthopedic implants.

English

English Deutsch

Deutsch Español

Español français

français 日本語

日本語 русский

русский 한국어

한국어 italiano

italiano português

português العربية

العربية Türkçe

Türkçe 中文

中文